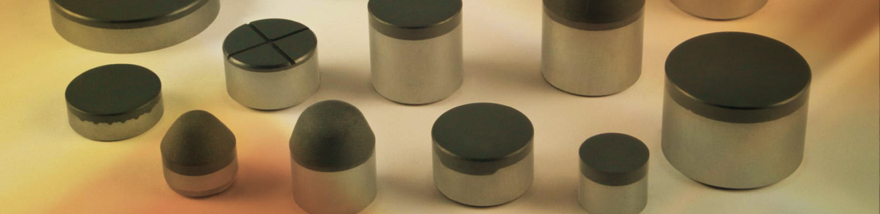

1:Product Name:PDC cutter for mining and Chain saw

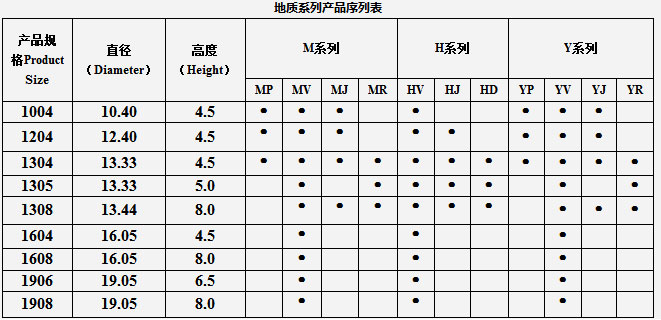

With the introduction of U.S. technology and the adoption of new high-efficiency catalysts and new processes, the geological series of diamond compacts have a high wear ratio and impact resistance, and at the same time improve the bonding between the diamond layer and the carbide interface, and improve the stress distribution. The joint surface is more solid, greatly improving the reliability and service life of the product, and has a higher cost performance.

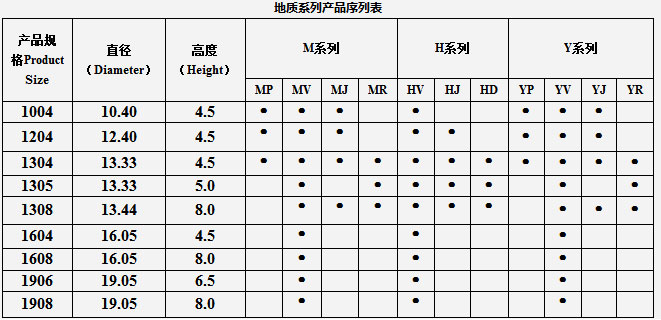

Geological series product sequence table

2: PDC Cutter for drilling oil and gas

Product Name: Diamond PDC Sheet Petroleum

Product details:

The company's oil-based diamond composite sheet introduced US technology, using a higher level of diamond powder and cemented carbide substrate, using new high-efficiency catalysts and new processes, with a complete CC bond between the diamond grains in the polycrystalline diamond layer. The microscopic characteristics of the bond enable the diamond layer to have high strength, high hardness and high wear resistance. Using a variety of tooth structure and special post-processing technology, effectively reduce the residual stress of the diamond composite sheet, the interface is more solid and uniform, with high thermal stability and strong impact toughness.

YD series

YD series is our best-selling product. With a variety of tooth structure and special post-processing technology, it has high thermal stability and strong impact toughness.

|

SIZE |

1919 |

1916 |

1913 |

1910 |

1908 |

1619 |

1616 |

1613 |

1610 |

1608 |

|

D(mm) |

19.05 |

19.05 |

19.05 |

19.05 |

19.05 |

16.05/15.88 |

16.05/15.88 |

16.05/15.88 |

16.05/15.88 |

16.05/15.88 |

|

H(mm) |

19.0 |

16.0 |

13.2 |

10.0 |

8.0 |

19.0 |

16.0 |

13.2 |

10.0 |

8.0 |

|

SIZE |

1313 |

1310 |

1308 |

1008 |

0808 |

|

|

|

|

|

|

D(mm) |

13.44 |

13.44 |

13.44 |

10.0 |

8.0 |

|

|

|

|

|

|

H(mm) |

13.2 |

10.0 |

8.0 |

8.0 |

8.0 |

|

|

|

|

|

EM series

The EM series is an alternative product to the YD series. Apart from the advantages of YD, EM has been significantly improved in terms of product performance, especially wear resistance, and its wear resistance has been adapted to the PDC bit for oil drilling in the international market in recent years. The new requirements of the company have quickly become popular with customers both at home and abroad.

|

SIZE |

1919 |

1916 |

1913 |

1910 |

1908 |

1619 |

1616 |

1613 |

1610 |

1608 |

|

D(mm) |

19.05 |

19.05 |

19.05 |

19.05 |

19.05 |

16.05/15.88 |

16.05/15.88 |

16.05/15.88 |

16.05/15.88 |

16.05/15.88 |

|

H(mm) |

19.0 |

16.0 |

13.2 |

10.0 |

8.0 |

19.0 |

16.0 |

13.2 |

10.0 |

8.0 |

|

SIZE |

1313 |

1310 |

1308 |

1008 |

0808 |

|

|

|

|

|

|

D(mm) |

13.44 |

13.44 |

13.44 |

10.0 |

8.0 |

|

|

|

|

|

|

H(mm) |

13.2 |

10.0 |

8.0 |

8.0 |

8.0 |

|

|

|

|

|

EH series

The EH series is a high-end product developed by our company. Both the wear resistance and impact resistance have advanced international standards. Suitable for drilling in hard formations and ultra deep drilling.

|

SIZE |

1919 |

1916 |

1913 |

1910 |

1908 |

1619 |

1616 |

1613 |

1610 |

1608 |

|

D(mm) |

19.05 |

19.05 |

19.05 |

19.05 |

19.05 |

16.05/15.88 |

16.05/15.88 |

16.05/15.88 |

16.05/15.88 |

16.05/15.88 |

|

H(mm) |

19.0 |

16.0 |

13.2 |

10.0 |

8.0 |

19.0 |

16.0 |

13.2 |

10.0 |

8.0 |

|

SIZE |

1313 |

1310 |

1308 |

1008 |

0808 |

|

|

|

|

|

|

D(mm) |

13.44 |

13.44 |

13.44 |

10.0 |

8.0 |

|

|

|

|

|

|

H(mm) |

13.2 |

10.0 |

8.0 |

8.0 |

8.0 |

|

|

|

|

|

Specially shaped PDC cutter

Product details

It is mainly used for geological drilling. This type of product combines the advantages of both flat and spherical composite sheets. Under the premise of ensuring wear resistance, the product's impact resistance is further improved.

|

Product number |

Diameter(mm) |

Height(mm) |

Diamond layer thickness(mm) |

|

1305 |

13.33 |

5.0 |

0.9-1.1 |

|

1308 |

13.33 |

8.0 |

0.9-1.1 |

|

1313 |

13.44 |

13.20 |

1.0-1.3 |

Product details

The ridge-shaped diamond composite sheet is a new type of diamond composite sheet introduced by our company.

The product has high abrasion resistance and strong impact toughness. Because this kind of composite sheet adopts a special inclined surface structure design, it can not only prevent the local stress concentration of the composite sheet, but also reduce the occurrence of collapse of the composite sheet. Mainly used in the manufacture of oil drill bits and coal fields, geological drills.

|

Product number |

Diameter(mm) |

Height(mm) |

|

WG1308 |

13.44 |

8.00 |

|

WG1305 |

13.33 |

5.00 |

Polish&Drill

Polish&Drill

Machines

Machines