YOU ARE HERE >

HOME >

DIAMOND SEGMENT

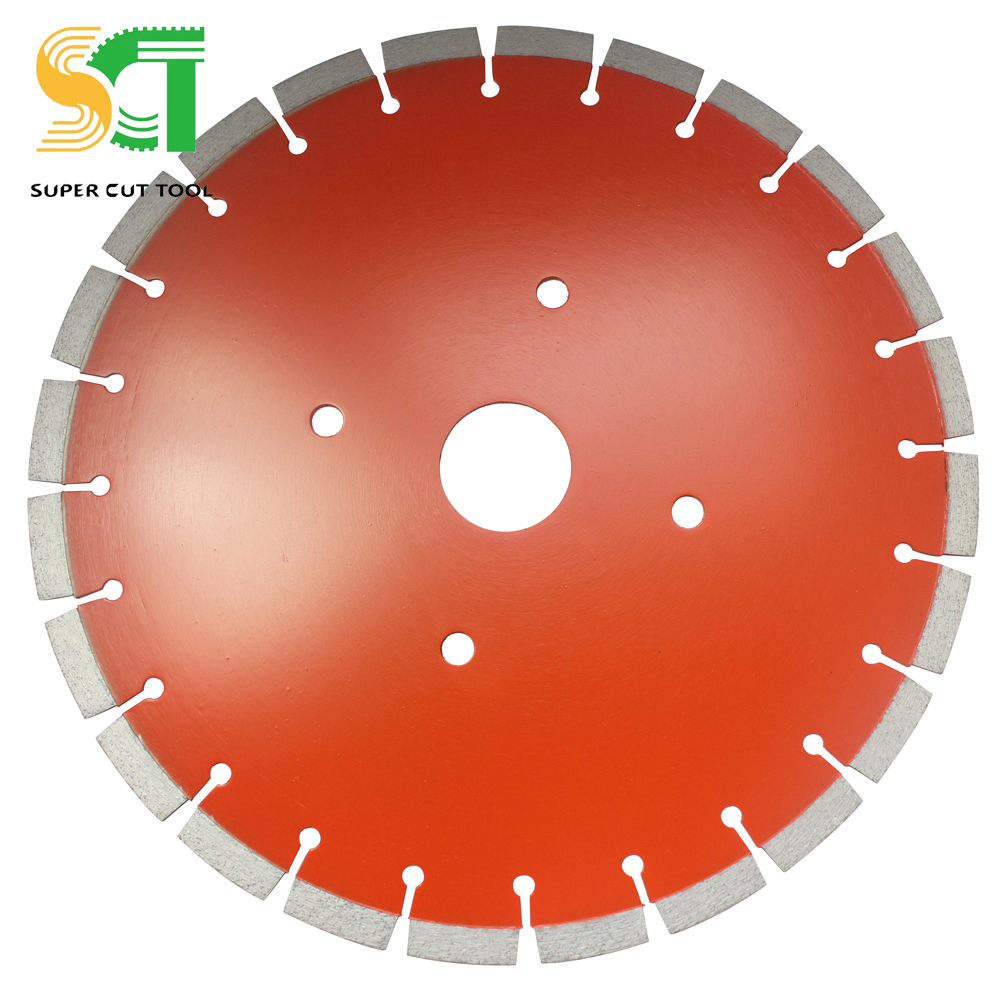

How to choose a good quality diamond circular saw blade

Publish Date:2020-12-31

In recent years, with the continuous development of the stone industry, especially the vigorous development of natural stone and artificial stone, the diamond tools industry has also experienced explosive growth. Many people don't understand saw blades, so there are some bad businesses that only focus on profit and not quality. Inferior products not only reduce work efficiency, increase costs, but also put operators in danger. So what kind of saw blade is better quality? Through the following five-point detection methods, we can probably understand the pros and cons of the selected saw blades, which is convenient for everyone to compare.

The weight is used to distinguish. Generally speaking, the heavier the saw blade of the same specification and material, the better, especially the large saw blade. The saw blade blade is certain, if the weight differs a lot, then the steel part must be faulty , Either the rigidity is insufficient, or the toughness is not enough, so when selecting a saw blade, load bearing can help us choose a better saw blade.

Listen to the sound and tap the erected saw blade with your fingers. The saw blade with dull sound has a thicker steel body, while the saw blade with crisper sound has poor steel body quality, do not to choose it.

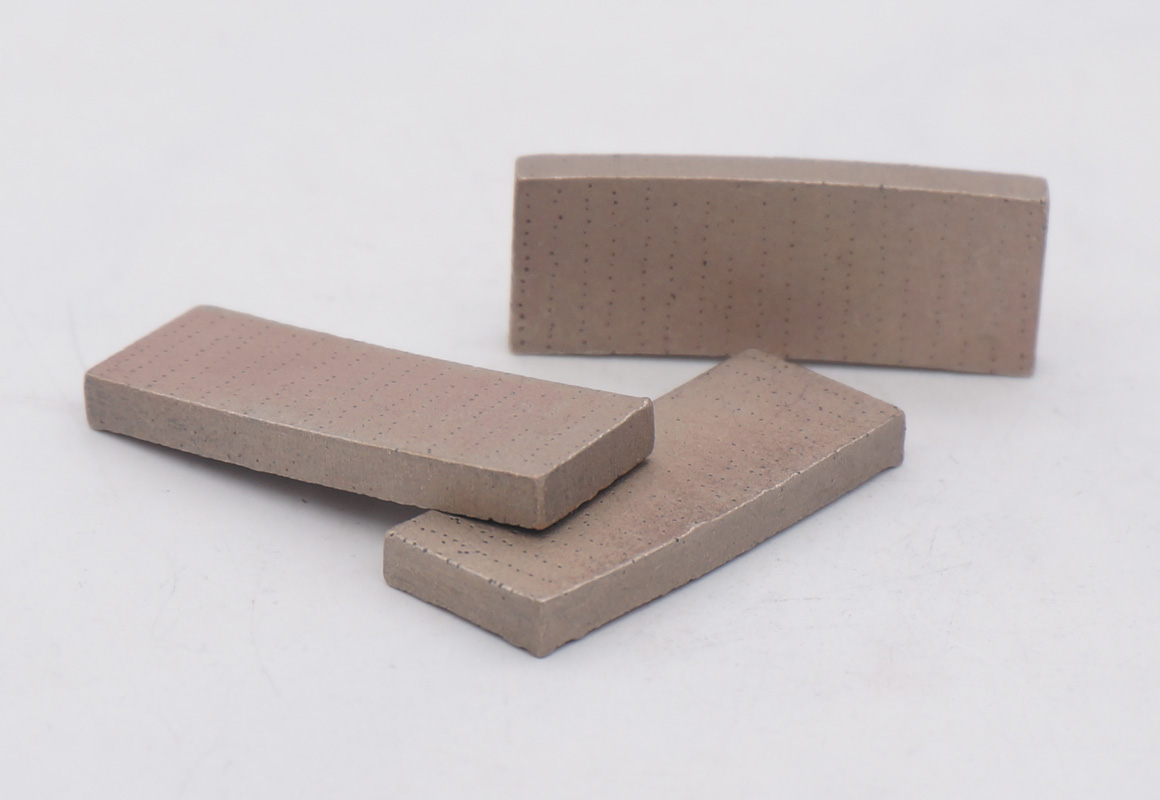

Observe whether the concentration and distribution of the exposed diamond on the marble saw blade segment is uniform. In order to reduce the cost of the inferior saw blade, the method of reducing the diamond content is used to reduce the cost. The process is extremely simple, and the uneven mixing of the diamond causes uneven force surface , After the buyer uses it, not only can’t cut, but also consumes quickly. A good diamond saw blade will see that the diamond distribution of the segment is extremely uniform, and the color and lines of the segment are also very clear. If it is impossible to observe with the naked eye, you can use a magnifying glass or a mobile phone to observe at a macro distance. The higher the diamond concentration, the larger the particles, and the evenly distributed saw blade is a good product.

Look at the color of the blade. The normal granite saw blade has the natural color of iron. The color of the blade is preferably off-white. The inferior granite saw blade is dark because it contains more impurities. For marble saw blades, the color of the blade head is better than golden yellow, while the color of brown is not good. Of course, some manufacturers will choose different binders, and the color of the formula is different, but the overall color is uniform, and it is better for the segment to not blacken.

The cutting effect is also a very important factor. It is mainly manifested in cutting edge smooth without chipping. If the chipping occurs, the saw blade is not very good, especially for cutting some soft stones with uneven cuts, chipped edges or missing corners, it is all caused by poor quality saw blades.

Inferior marble saw blades use inferior diamond powder which low level degree of wear resistance. It make the diamond saw blades not durable, and some manufacturers will the diamond powder from the waste segment. The biggest feature of such a segment is not stable enough, and the diamond is opaque, and seriously carbonization, which leads to problems such as low life and low efficiency of the saw blade.

If the selection of saw blades is still not possible, the quality of diamond saw blades produced by SCT is guaranteed. Higher quality diamonds are used. It is worry-free after sale. Once quality problems occur, SCT will provide a complete compensation plan to provide worry-free services for customers.

Tags:

The control ratio of the metal content in the diamond segment bond

2020-08-17

The diamond segment is composed of two parts of the bond and the diamond, and the bond is actually not just one component, it is made of paraffin, nickel, tin, zinc, copper, iron, silicon carbide, tungsten and other metal powders, and non-metallic powder, in which copper, iron, silicon carbide and tungsten are the main components, while nickel, tin, and zinc are the metal binders, which make the diamond and the bond more firmly....

Selection of diamond powder for diamond segment

2020-09-24

During the diamond segment working process, the role of diamond powder crystals is very important, especially in the cutting process, a good crystal can be very good in anti-breakage ability, reduce the power consumption of the equipment, and extend the life of the cutting....

Arrayed diamond segment and the saw blade

2020-12-29

In traditional diamond segment products, the diamond powder in the segment is arranged in disorder. During the cutting process, the exposed diamond will impact the stone surface at various angles, and the exposed height of the diamond will vary. As a result, the diamond is not evenly stressed, and diamonds with high exposure are prone to fracture. In order to improve this situation and make the diamond distribution more uniform, arrayed segments have emerged. Weld the arrayed segment on the blade steel body to be an arrayed saw blade....

Commonly used bond for diamond segment

2020-09-09

There are four commonly used bonds for diamond segment. These four bonds are matched with different diamond powders according to different materials to make diamond segments for different purposes. Each bond has its advantages and disadvantages. In the process of designing the diamond segment, we must take advantage and reinforce its shortcomings. This is the charm of diamond segment production and design....

Common problems and treatment methods of diamond segment

2020-08-17

Diamond segment is a non-standard industry in modern industry. The instability of product quality is the most common problem. The following are some of the most prone problems and related solutions in producing diamond segments. Through these instructions, Let everyone better understand the details of diamond segments production process....

Formula design of diamond segment

2020-10-16

Diamond segment is a very special segmented product. Through different formulas and different processes, products with different appearances, different cutting performances and different cutting life can be produced. The most attractive part of this product is that it is not Certainty, especially the new formula, needs to consider factors such as the object to be processed, the matrix metal bond, diamond grade and particle size, pressure and sintering temperature....

RETURN

RETURN