Polish&Drill

Polish&Drill

+

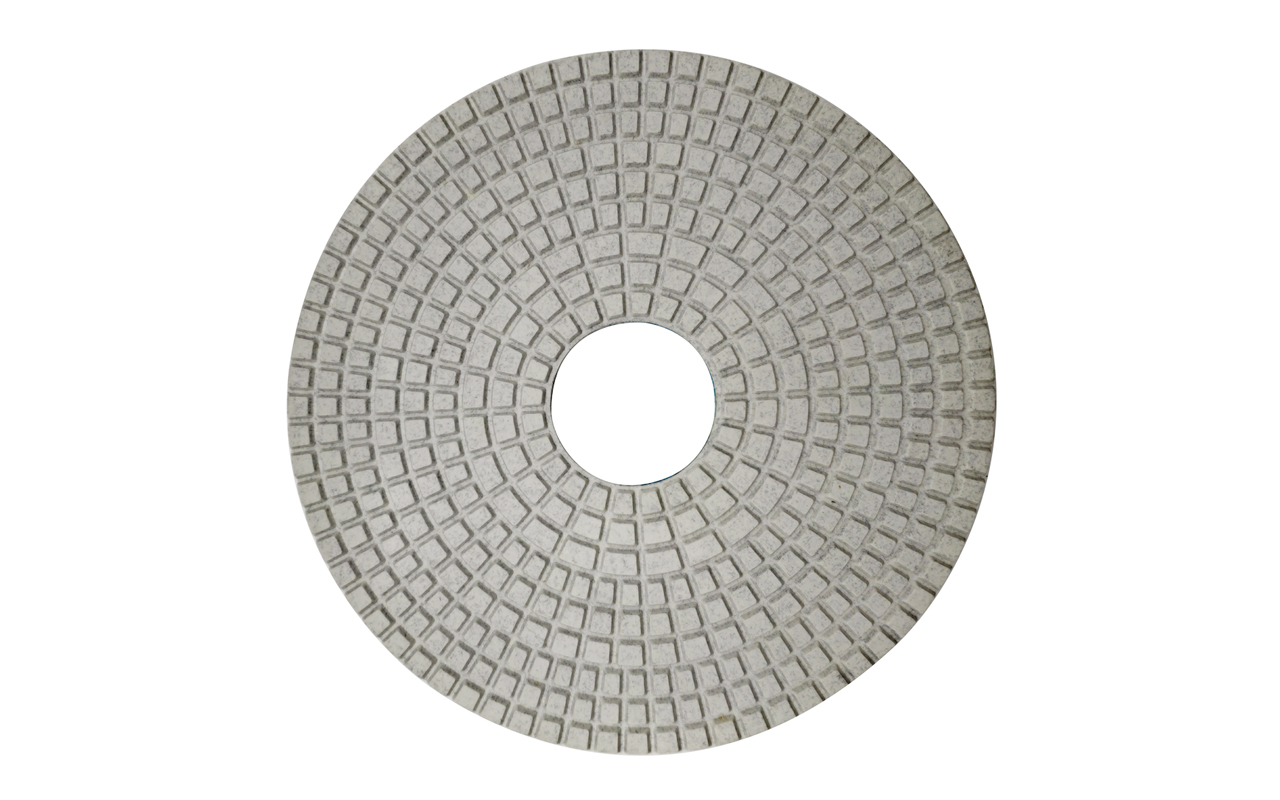

Product description

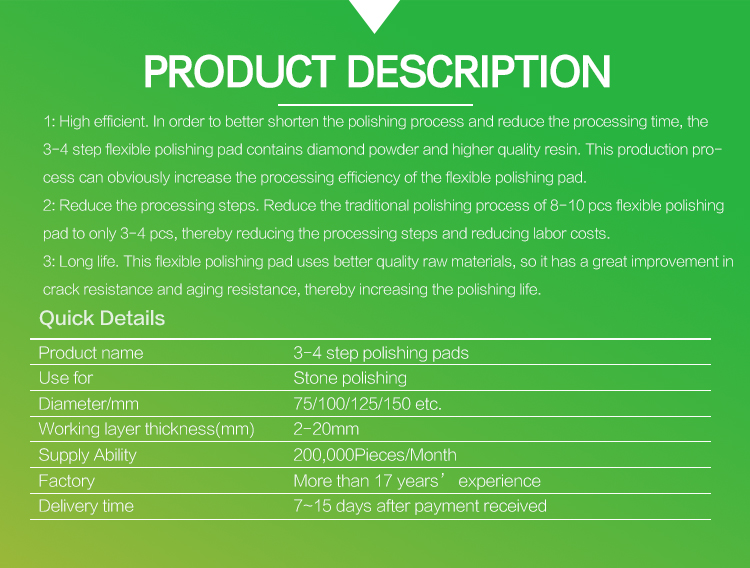

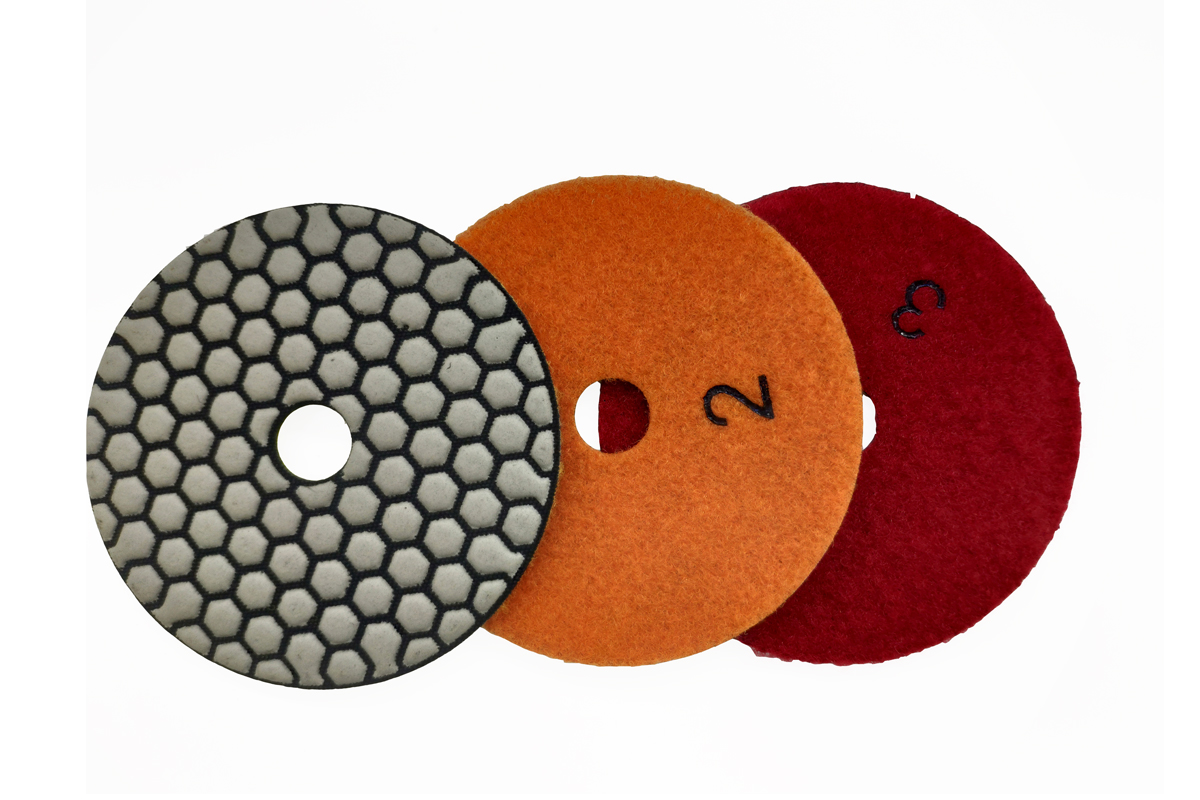

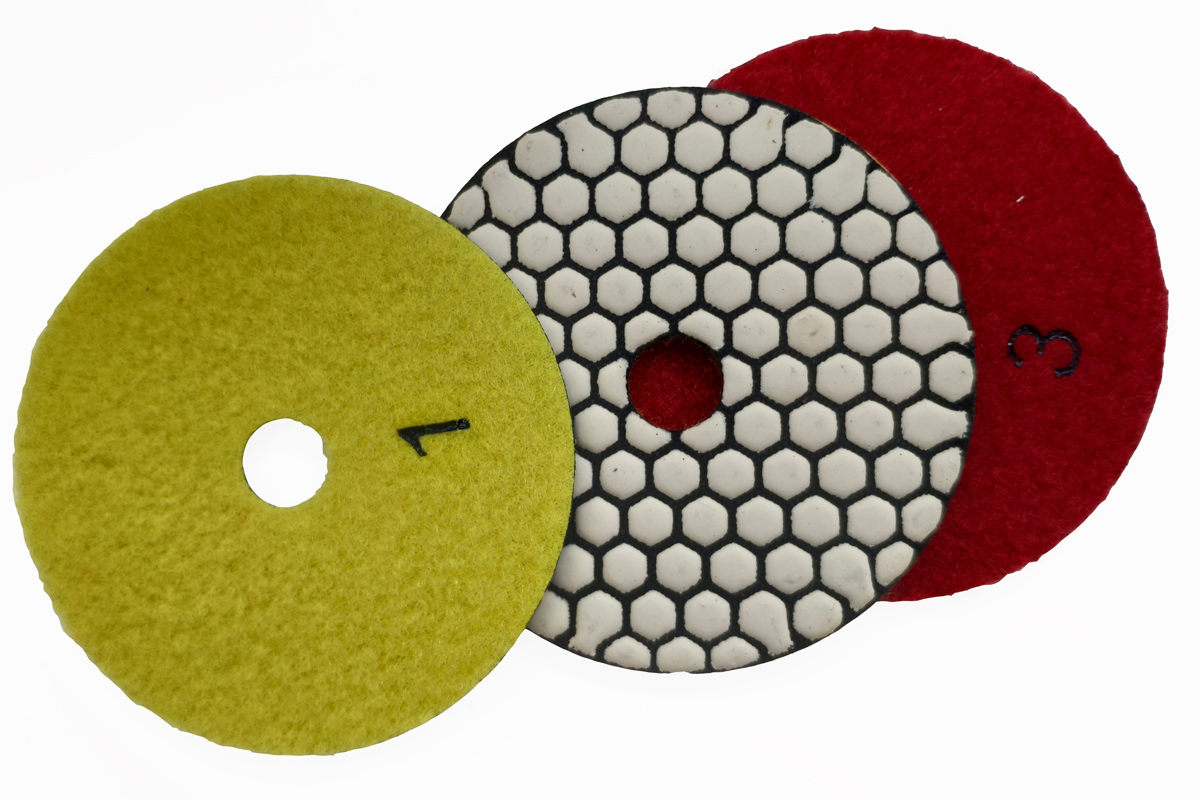

1: High efficient. In order to better shorten the polishing process and reduce the processing time, the 3-4 step flexible polishing pad contains diamond powder and higher quality resin. This production process can obviously increase the processing efficiency of the flexible polishing pad.2: Reduce the processing steps. Reduce the traditional polishing process of 8-10 pcs flexible polishing pad to only 3-4 pcs, thereby reducing the processing steps and reducing labor costs.

3: Long life. This flexible polishing pad uses better quality raw materials, so it has a great improvement in crack resistance and aging resistance, thereby increasing the polishing life.

Application for material: Granite/Marble/Artificial stone, ceramic, concrete, etc.

Grit size: 50~3000#, as customized.

Product specification

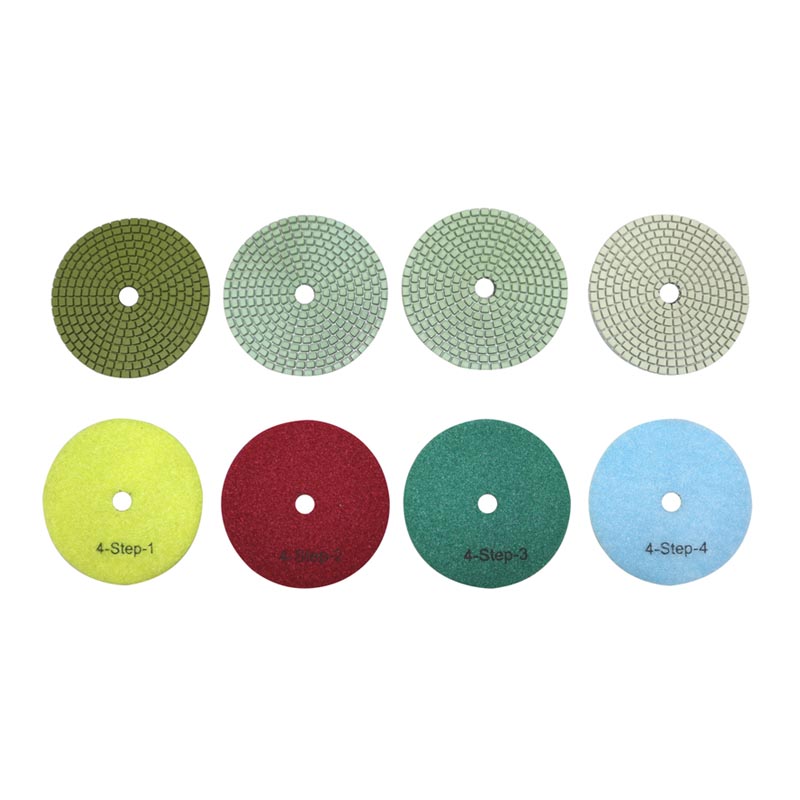

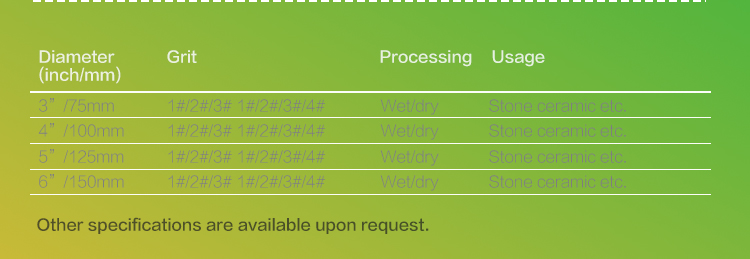

| Diameter(mm) | Thickness(mm) | Grit No. | Processing project | Use |

| 3”, 4”, 5”, 6” | 2-10mm | 1#,2#,3#,4# | stone | Wet and dry |

Machines

Machines