Diamond fickert length and style

Publish Date:2020-12-31

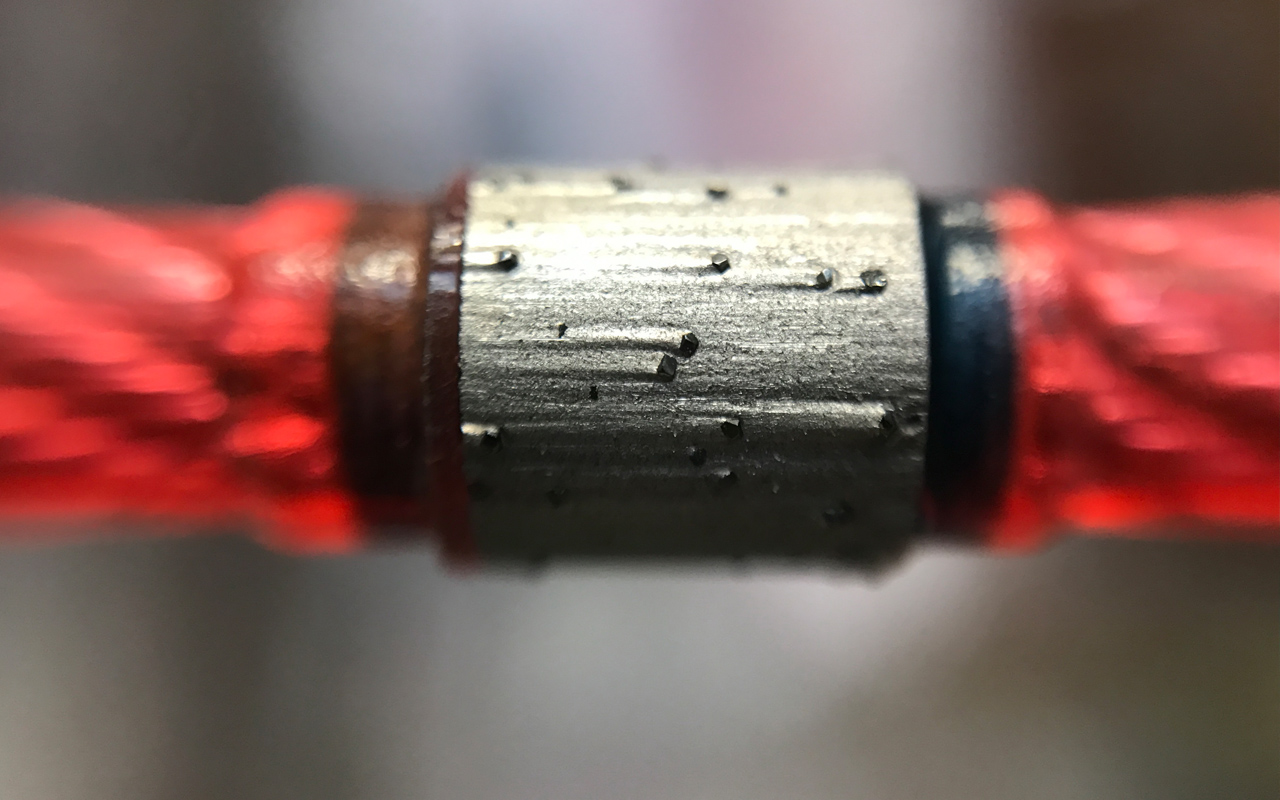

Diamond fickertce is an important tool for granite grinding. The coarsest grain size is 36#, and the finest is 320#. According to the arrangement rules of abrasives, the combination of nearly twice the grain size can be used a combination, such as 36#, 60#, 100#, 180#, 320# which can save polishing materials to the greatest extent and achieve the most material-saving and energy-saving processing method. If the strict request for slab flatness, you can choose 46#, 80#, 140#, 240# combination, but will have a greater impact on the consumption of the resin fickert used later.In terms of length, the 130mm long diamond fickert is used for the polishing of ceramic tiles, artificial quartz stone and other product lines, because most of these slabs are relatively smooth and have a small contact area, which saves processing time and processing costs, and also reduces the consumption of the abrasive. 135mm length diamond fickert is used for easy-to-polish granite, that is, softer granite, because the small length means that the overall polishing surface is small, and the contact area is small, which will result in insufficient polishing gloss, but for medium-soft granite, 135mm The diamond fickert is the most economical and has a good polishing effect. Most of the granite is medium-hard material. The 140mm length diamond fickertce can basically meet the processing of this kind of stone. During the polishing process, the contact area of the fickert and the stone is appropriate, and the rough grinding effect can basically be satisfied. The 170mm long diamond fickertce is relatively rare, and it is mainly used for the harder stone to increase the friction surface and make the diamond fickert more in contact with the stone, thereby obtaining a better polishing effect. In general, the hardness of the stone directly determines the length of the diamond fickert. The harder the stone, the longer the diamond fickert will have a better processing effect. Of course, the higher the processing cost will follow. For example, if the electricity bill increases, the cooling water requires a larger flow rate, but there are also benefits. The longer the diamond fickert, if the stone requires the same brightness, the line speed of the automatic grinding machine can be appropriately increased to increase production efficiency.

The styles of diamond fickert are mainly divided into two categories. The first category is slotted, also called toothed fickert. The surface of the fickert is divided into many pieces, and the common one is two pieces with a groove in the middle. Divided teeth, two grooves, three divided teeth, and three grooves, four divided teeth. The grooves can be divided into oblique grooves and straight grooves. With this distinction, the style of the diamond fickert has increased. But no matter what, the slotted diamond fickert has three important characteristics:

1: Better cooling. During the polishing process, the diamond fickert and the stone are polished to generate a lot of heat. During the processing of the slotted fickertce, the water flow can not only reduce the temperature around the fickert, but also follow the groove, enter the inside of the fickert, so as to better cool down, keep the diamond fickert at a lower temperature, so as to maintain the stability of the agglomeration of the fickert.

2: Better removal of burrs and bumps, the agglomerated fickertce has better grinding ability, especially on both sides of the groove, forming a natural grinding surface, which can remove uneven burrs and stone crystals on the slab, thereby Make the surface smoother. Whether it is diagonal or straight, it is to better deal with this problem.

3: The grooved fickertzil reduces the processing area and increases the pressure under certain pressure. Therefore, the diamond fickertzil will have a higher polishing efficiency during the polishing process and will produce a good polishing effect.

The second type is continuous type fickert, also known as one-piece fickert, this type of fickert is the shape of the original diamond fickert, more traditional structure, this type of fickert also has several advantages:

1: Longer life, this kind of fickert has no grooves, so when the length and height are certain, the raw materials used are larger than the slotted fickert, so the cost is higher, of course, the life must be longer.

2: The grinding effect is good, the contact area of this kind of fickert and the stone slab is large, so the polishing effect is higher than that of the grooved fickertzil.

In general, when choosing a diamond fickert, you must pay attention to the length and style. These factors also seriously affect the life and efficiency of the diamond fickert.

Tags:

Polishing technology and principle of natural stone

2020-08-17

Natural stone needs to face the most basic technological processes such as cutting, grinding and polishing during the processing. Polishing is an important step in stone processing. We need to understand the polishing process and principles of stone processing, so as to facilitate us to master stone processing Basic knowledge also gives us a better understanding of the stone industry....

Diamond fickert length and style

2020-12-31

The shape of the diamond fickert has already been determined in terms of styling. The main difference lies in the change of its length and the style. Generally speaking, the commonly used lengths of the diamond fickert are 130mm, 135mm, 145mm, 170mm. On the one hand, abrasive agglomeration can be divided into two types: slotted and continuous. This article mainly introduces the influence of diamond fickert different lengths and different styles of on stone processing....

Granite Polishing Products-Metal bond diamond fickert afickertsive

2020-12-31

Diamond fickert is a product used in the automatic granite polishing line. It is mainly used in fickert-type polishing machine. The biggest feature of this machine is that there are 6-7 firkets installation grooves on the bottom of the polishing head. It is used for rough grinding of granite slabs, so it is placed at the front of the granite polishing line, and the front is connected with the califickertting afickertsives....

Resin bond diamond fickert

2020-12-31

Diamond is the main tool for grinding stone. After rough grinding the granite slab with metal bond diamond fickert, it is necessary to further process the stone that has completed the rough grinding process. At this time, the resin bond diamond fickert which made by diamond and resin bonded came into being. This kind of product performs finer grinding on the surface of granite slabs, also known as fine grinding. After fine grinding, the surface of the slab is basically flat and presents a matt surface....

Introduction of diamond fickert

2020-10-16

Diamond fickert is a common abrasive used in stone polishing machinery. It is mainly composed of diamond segment and steel base. The steel base part is used to be fixed on the grinding head of the polishing machine. A grinding head can be inlaid with 6-7 pieces diamond fickert. During the operation, the diamond fickert polishes the slabs in all directions through the rotation of the grinding head on the polishing machine and the forward and backward movement of the grinding machine crossbeam....

Diamond fickert production process

2020-12-31

Diamond fickert is composed of steel base and fickert abrasive block. In the process of producing diamond fickert, the steel base is basically purchased from alloy steel supplier. The steel body material requires high temperature resistance and must can be formed into a compact one-piece structure with the fickert abrasive block, and the other part is the fickert abrasive block, which is also the focus of this article....

RETURN

RETURN