Diamond fickert production process

Publish Date:2020-12-31

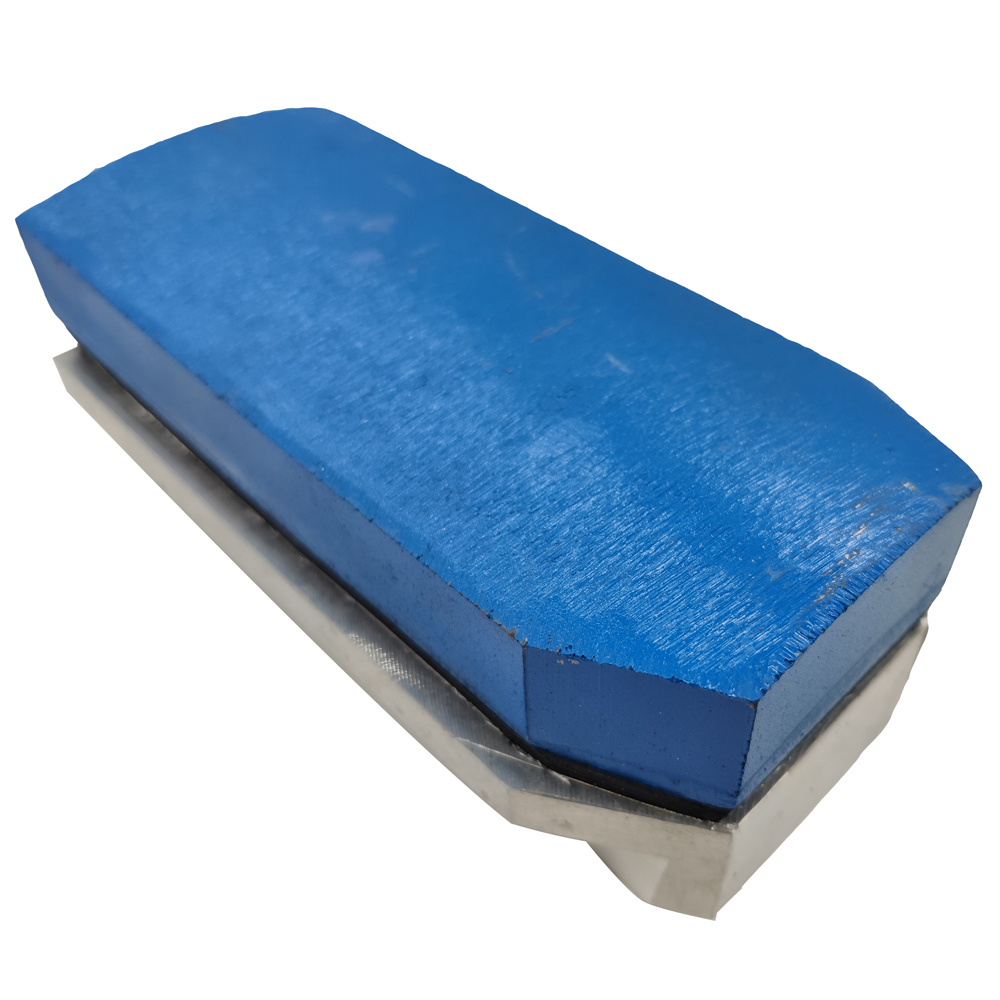

The most important part of the diamond fickert is the part used to polish the stone. It is generally called the diamond fickert grinding block and also known as the fickert segment. This kind of grinding block is formed by the combination of diamond powder and metal matrix binder, which can be used for rough grinding and fine grinding of natural stone slab.

The production of diamond fickert grinding blocks is extremely important, because the main cutting material diamond powder is contained here, below, we will detail the production steps of diamond fickert grinding blocks:

Material selection: usually we select it according to the different hardness of the stone and the diamond particle size required by the customer. Generally speaking, the metal bond materials required for the coarse grit and fine grit diamond fickert are different. Therefore, the selection of materials must be cautious and must not be confused.

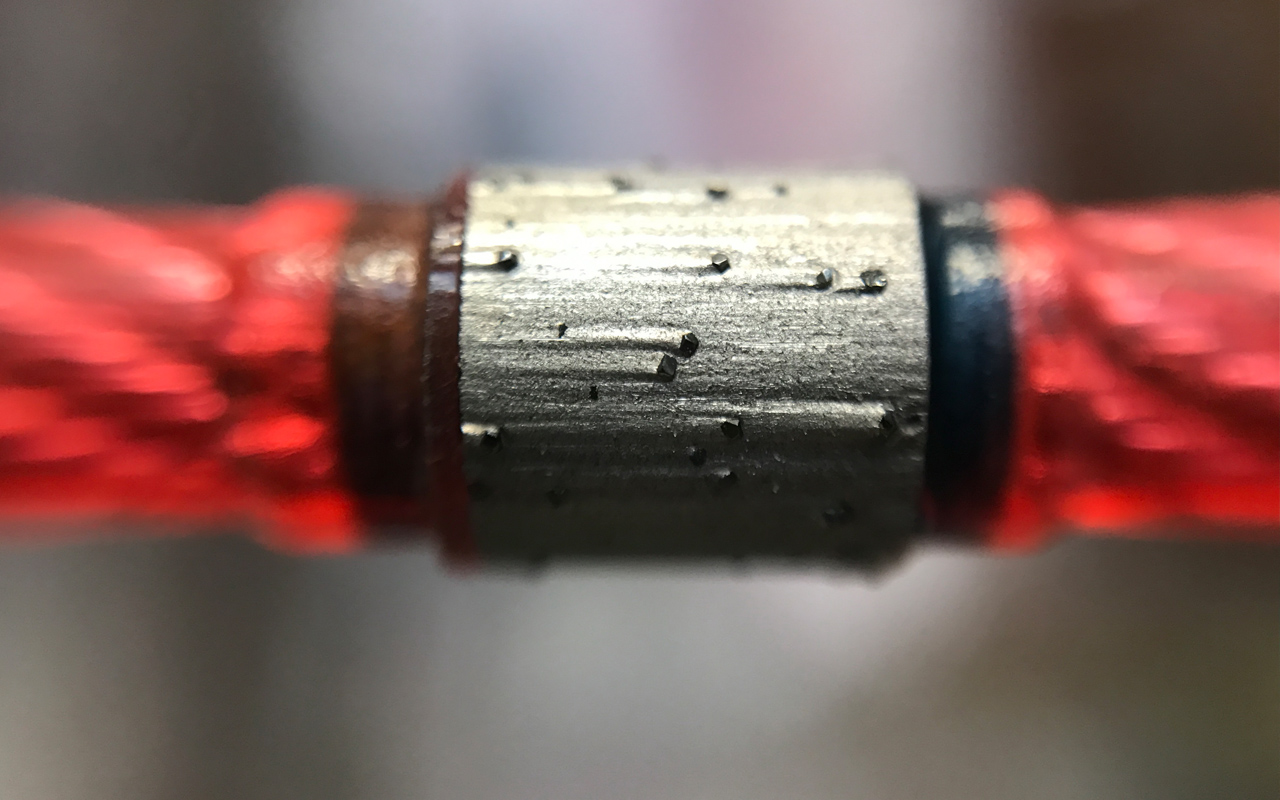

Stirring: Put the diamond and metal bond of different particle sizes into the stirring equipment, and mix the powder evenly through long-term stirring. After the stirring is completed, the diamond is evenly dispersed in the metal powder to prepare for the later sintering.

High-temperature and high-pressure sintering: Put the mixed powder into a graphite mold and distribute it according to weight. In the automatic sintering machine, set the heating temperature, holding time, boost pressure, holding pressure and other data for sintering.

Cooling and demoulding: The sintered diamond fickert is cooled at room temperature. After cooling, the diamond fickert block is separated from the graphite mold.

Trimming and post-treatment: The diamond fickert block from the graphite mold will have some appearance problems, which need to be polished, trimmed, and some anti-rust treatments will be carried out.

The processed diamond grinding block should be fixed on the steel base, which is usually done by bolt fixing. The shock absorber must be added during the fixing process to prevent rigid fracture during the diamond fickert working. In addition to fixing bolts, in the design of the steel base, in order to better combine the diamond grinding block with the steel base, a dovetail groove design or a diagonal groove design is generally adopted to allow the grinding block to be stuck into the groove of the steel base through physical stress. The connection will make the diamond fickert stronger and the structure more stable.

In general, the diamond fickert production process can be attributed to the production of diamond grinding block, the purchase of steel base, bolts, and shock-absorbing materials, and finally the fixation of them.

Tags:

Polishing technology and principle of natural stone

2020-08-17

Natural stone needs to face the most basic technological processes such as cutting, grinding and polishing during the processing. Polishing is an important step in stone processing. We need to understand the polishing process and principles of stone processing, so as to facilitate us to master stone processing Basic knowledge also gives us a better understanding of the stone industry....

Diamond fickert length and style

2020-12-31

The shape of the diamond fickert has already been determined in terms of styling. The main difference lies in the change of its length and the style. Generally speaking, the commonly used lengths of the diamond fickert are 130mm, 135mm, 145mm, 170mm. On the one hand, abrasive agglomeration can be divided into two types: slotted and continuous. This article mainly introduces the influence of diamond fickert different lengths and different styles of on stone processing....

Granite Polishing Products-Metal bond diamond fickert afickertsive

2020-12-31

Diamond fickert is a product used in the automatic granite polishing line. It is mainly used in fickert-type polishing machine. The biggest feature of this machine is that there are 6-7 firkets installation grooves on the bottom of the polishing head. It is used for rough grinding of granite slabs, so it is placed at the front of the granite polishing line, and the front is connected with the califickertting afickertsives....

Resin bond diamond fickert

2020-12-31

Diamond is the main tool for grinding stone. After rough grinding the granite slab with metal bond diamond fickert, it is necessary to further process the stone that has completed the rough grinding process. At this time, the resin bond diamond fickert which made by diamond and resin bonded came into being. This kind of product performs finer grinding on the surface of granite slabs, also known as fine grinding. After fine grinding, the surface of the slab is basically flat and presents a matt surface....

Introduction of diamond fickert

2020-10-16

Diamond fickert is a common abrasive used in stone polishing machinery. It is mainly composed of diamond segment and steel base. The steel base part is used to be fixed on the grinding head of the polishing machine. A grinding head can be inlaid with 6-7 pieces diamond fickert. During the operation, the diamond fickert polishes the slabs in all directions through the rotation of the grinding head on the polishing machine and the forward and backward movement of the grinding machine crossbeam....

Diamond fickert production process

2020-12-31

Diamond fickert is composed of steel base and fickert abrasive block. In the process of producing diamond fickert, the steel base is basically purchased from alloy steel supplier. The steel body material requires high temperature resistance and must can be formed into a compact one-piece structure with the fickert abrasive block, and the other part is the fickert abrasive block, which is also the focus of this article....

RETURN

RETURN