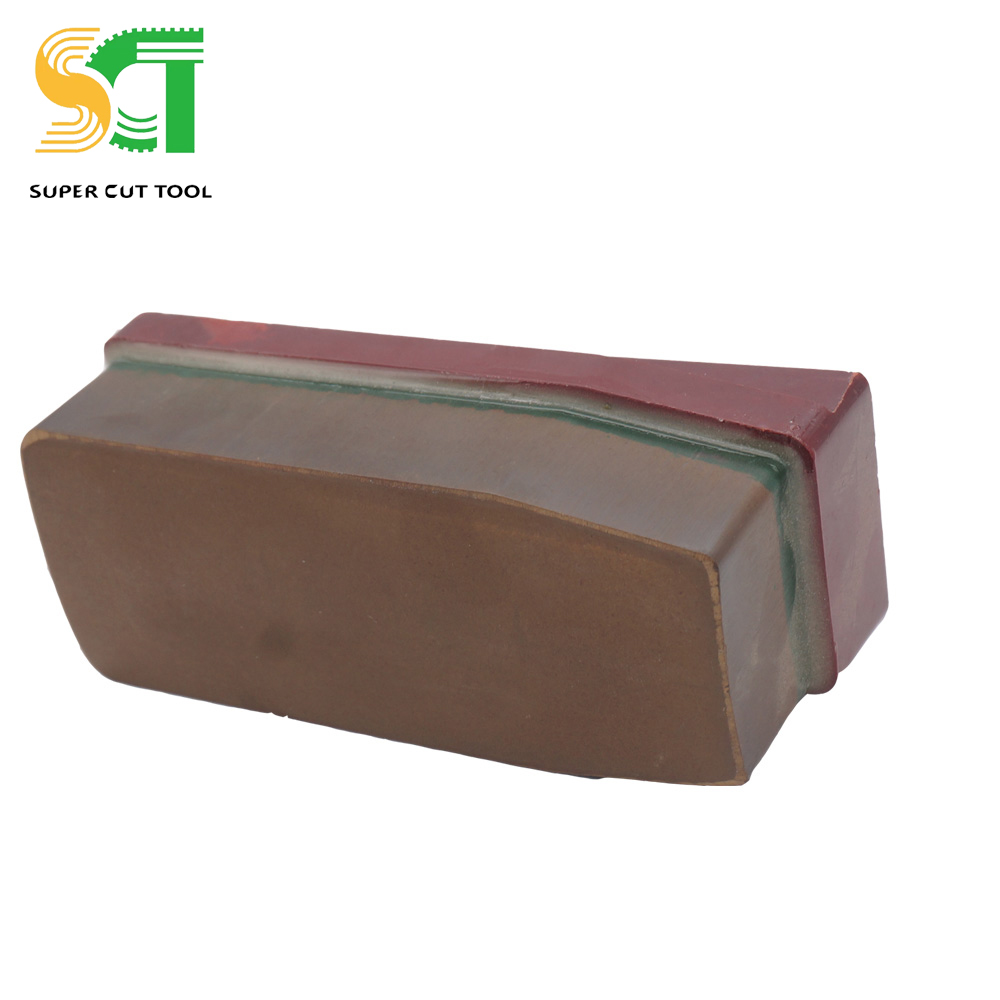

Resin bond diamond fickert

Publish Date:2020-12-31

In the early days, silicon carbide was used as the main abrasive for grinding stone, and phosphor-magnesium metal powder and cement were used as the bonding agent. This kind of traditional grinding block that has been commonly used has many problems, such as short service life, low processing efficiency, high work intensity, and low product gloss.

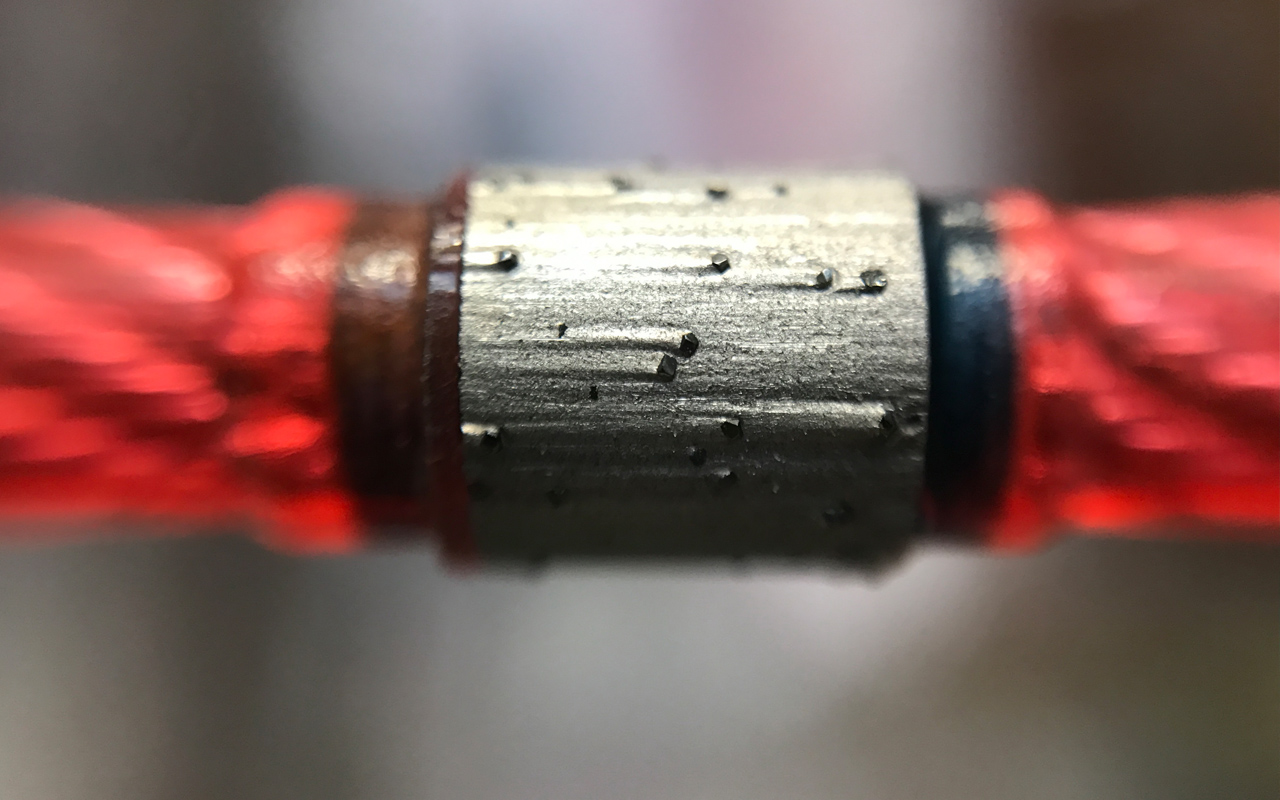

Later, diamond grinding blocks appeared, but the fixation of diamond grinding blocks to the base of the abrasive tool is a new issue. At present, there are inlaid diamond grinding blocks, in which diamonds are embedded on a metal substrate or a ceramic substrate, but in the actual production and use process, the effect is not ideal and the structure is complicated. There are also cases where a connecting steel plate is added between the base and the grinding block. The grinding block is welded to the connecting steel plate, and the connecting steel plate is bolted to the base. The entire manufacturing process is quite complicated and costly. In recent years, diamond fickert products have gradually matured, but only rough grinding can be carried out, and the problem of stone fine grinding is also in front of us.

With continuous efforts, people invented and created the resin bond diamond fickert. This product has a simple structure, low production cost, and a firm and reliable combination of the base and the grinding block; moreover, it has higher grinding efficiency and the acceptable polished product glossiness, so it gradually replaced the traditional abrasive. At present, it is widely used in fickert type polishing line.

The resin bond diamond fickert abrasive block includes a base and an resin bond grinding block. The grinding block is connected to the base through a connecting layer. The base is made of plastic or polyurethane. The abrasive block is made of polymer material (polyolefin plastic or unsaturated polyester). Resin or phenolic resin) is a diamond abrasive block with a bonding agent. The lower surface of the abrasive block is provided with pits or holes, and the upper surface of the base is provided with pits or holes. The abrasive blocks are connected by bonding resin The layer is connected and fixed with the base, and the bonding resin fills the pits or holes of the grinding block and the base. In terms of shape, the diamond resin fickert abrasive block is a rectangular block with two corners chamfered at one end. In terms of advantages, this diamond abrasive has the characteristics of high grinding efficiency, high gloss of processed granite, simple structure and low manufacturing cost.

The length of the resin bond diamond fickert is generally 135mm, 140mm, 170mm. Among them, the length of 140mm is more common. This kind of fickert contains finer-grit diamond powder, 120#, 180#, 240#, 320# , 400#, 600#, 800#, 1000#, 1200#, 1500#, 3000# are more common particle sizes, which are used in combination with the particle size of metal bond diamond fickert.

Rsin bond diamond fickert are used after metal bond diamond fickert and use them in the form of a set. How to match a set of reasonable rough grinding and fine grinding abrasives requires the operator to test the commonly used stones for a long time before getting a conclusion. In general, resin bond diamond fickert abrasive is the second step of granite polishing. A good resin bond diamond fickert can lay a good foundation for later stone polishing and save time and production costs for the subsequent polishing process.

Tags:

Polishing technology and principle of natural stone

2020-08-17

Natural stone needs to face the most basic technological processes such as cutting, grinding and polishing during the processing. Polishing is an important step in stone processing. We need to understand the polishing process and principles of stone processing, so as to facilitate us to master stone processing Basic knowledge also gives us a better understanding of the stone industry....

Diamond fickert length and style

2020-12-31

The shape of the diamond fickert has already been determined in terms of styling. The main difference lies in the change of its length and the style. Generally speaking, the commonly used lengths of the diamond fickert are 130mm, 135mm, 145mm, 170mm. On the one hand, abrasive agglomeration can be divided into two types: slotted and continuous. This article mainly introduces the influence of diamond fickert different lengths and different styles of on stone processing....

Granite Polishing Products-Metal bond diamond fickert afickertsive

2020-12-31

Diamond fickert is a product used in the automatic granite polishing line. It is mainly used in fickert-type polishing machine. The biggest feature of this machine is that there are 6-7 firkets installation grooves on the bottom of the polishing head. It is used for rough grinding of granite slabs, so it is placed at the front of the granite polishing line, and the front is connected with the califickertting afickertsives....

Resin bond diamond fickert

2020-12-31

Diamond is the main tool for grinding stone. After rough grinding the granite slab with metal bond diamond fickert, it is necessary to further process the stone that has completed the rough grinding process. At this time, the resin bond diamond fickert which made by diamond and resin bonded came into being. This kind of product performs finer grinding on the surface of granite slabs, also known as fine grinding. After fine grinding, the surface of the slab is basically flat and presents a matt surface....

Introduction of diamond fickert

2020-10-16

Diamond fickert is a common abrasive used in stone polishing machinery. It is mainly composed of diamond segment and steel base. The steel base part is used to be fixed on the grinding head of the polishing machine. A grinding head can be inlaid with 6-7 pieces diamond fickert. During the operation, the diamond fickert polishes the slabs in all directions through the rotation of the grinding head on the polishing machine and the forward and backward movement of the grinding machine crossbeam....

Diamond fickert production process

2020-12-31

Diamond fickert is composed of steel base and fickert abrasive block. In the process of producing diamond fickert, the steel base is basically purchased from alloy steel supplier. The steel body material requires high temperature resistance and must can be formed into a compact one-piece structure with the fickert abrasive block, and the other part is the fickert abrasive block, which is also the focus of this article....

RETURN

RETURN