YOU ARE HERE >

HOME >

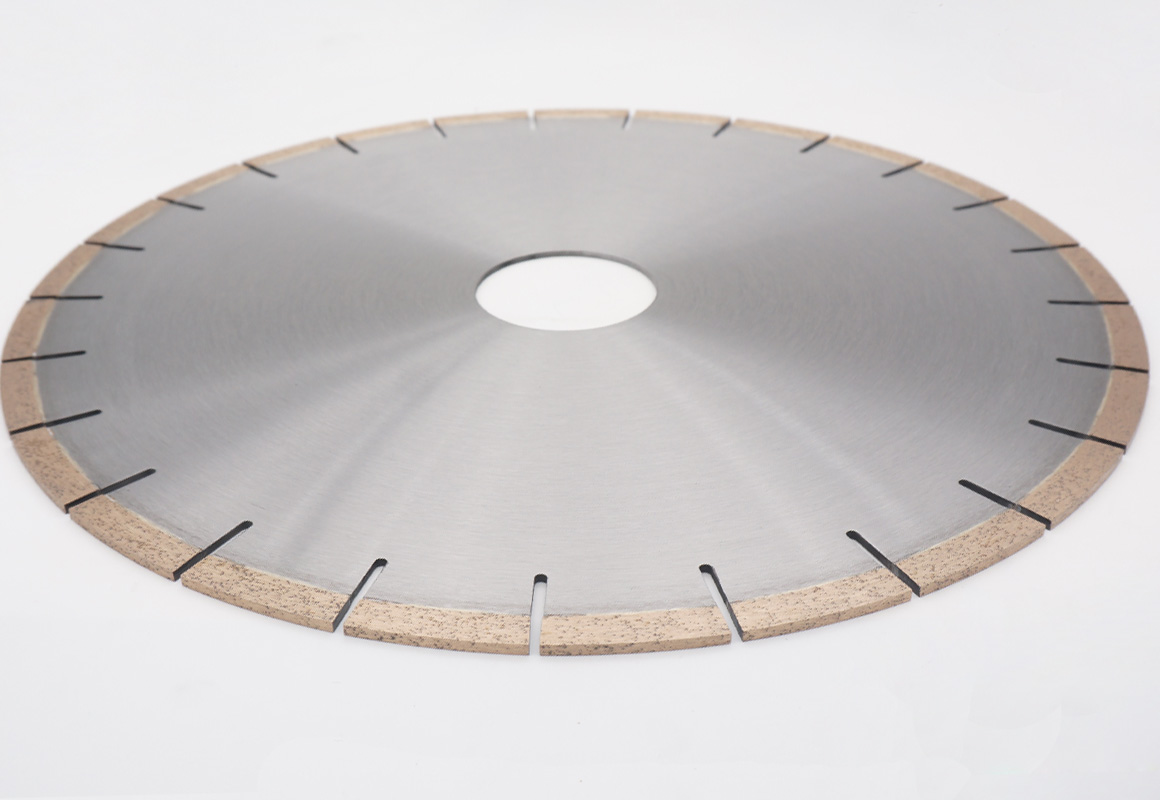

DIAMOND SAW BLADE

The role of the blade steel base in the diamond saw blade

Publish Date:2021-02-03

Everyone knows that a diamond saw blade is composed of a saw blade steel base and the segment. The segment is the main cutting part and is used for cutting. Besides fixing the segment and facilitating cutting, does the saw blade steel base have any other functions? In this article, we mainly introduce several other functions of the saw blade steel base.1: For the help of welding, in the process of welding the segment, if there is no saw blade steel base, then the welding cannot accurately grasp the welding straightness, so the welding will be very troublesome. With the saw blade steel base, after welding the first segment, no need to adjust the straightness, you can proceed to the next welding. For automatic welding machines, the saw blade steel base provides an accurate welding position for welding more conveniently.

2. Under the condition that the saw blade does not need intermediate maintenance or inspection, the segment on the base can be fully utilized: the saw blade steel base provides very clear inspection items for the inspection and repair of the saw blade, and people can fully understand the use of the saw blade by the segment. And half of the worn or slightly deformed saw blade steel base, if used for cutting edges, still has great utility value and will not affect the use.

3. By reducing the thickness of the saw blade steel base, reducing the cost of the segment, reducing sawing resistance and cutting loss: At present, most of the saw blades used in the market are still relatively thick, but with the continuous improvement of alloy steel technology, the market Ultra-thin alloy blade steel base have also begun to appear on the market. The thickness of these saw blade steel base is thin, and some are less than half or less of the previous thickness. The continuous maturity of these products can reduce cutting consumption and energy consumption, and is environmentally friendly and energy-saving, it is the future development direction of diamond saw blades.

4. After re-welding segment, the cost of leveling and straightening is low. The saw blade steel base is very friendly to secondary welding, especially for the adjustment of flatness. After the secondary welding, since the weld seam of the first welding still exists, it is very simple to fix and easy to adjust.

5. Many times of repeated use. The saw blade is reused many times to reduce the use cost. If the saw blade steel base is not selected, the segment and the saw blade are connected as a whole, the cost of the diamond saw blade will be very high, which will affect the cost of stone processing.

6. The saw blade steel base can conduct heat, and the segment generates a lot of heat during the cutting process. The heat is dispersed through the saw blade steel base, and the segment can work in a stable and good environment under rapid rotation and water cooling.

7: Share the impact force of the segment. Although the segment can disperse part of the impact force in the diamond grinding process, there is still a large impact force acting on the saw blade steel base, and the saw blade steel base also plays a role in impact resistance, ensuring the cutting of the segment performance.

Tags:

.jpg)

Installation and use process of diamond circular saw blade

2020-11-09

Diamond saw blades can be used in single blade saw, multiblade saws, infrared bridge cutting machines, hand cutter and other large and medium-sized stone machinery according to their sizes. They can also be used in angle grinders, hand cutting machines etc., the small machines are used in a wide range. This article is mainly based on the application of different saw blades in installation and cutting....

.jpg)

Diamond circular saw blade classification

2020-11-09

Diamond circular saw blades are mainly classified according to size. Generally speaking, they are divided into small-diameter saw blades, medium-diameter saw blades and large saw blades. Small saw blades are also divided according to the shape of the blade, while medium-diameter saw blades can be divided according to the cutting material or the shape of the segment, and the large saw blade is divided according to the purpose. This article introduces the classification of circular saw blades to let you better understand the relevant knowledge of diamond saw blades....

The development of diamond saw blades

2020-09-24

Among all diamond tools, diamond saw blades are the first to appear. With saw blades, cutting becomes simple. Cutting changes the entire world. In terms of decorative materials, wood is not the only choice. Stone, artificial stone, and ceramic tiles are used extensively. In terms of engineering, the cutting of asphalt, reinforced concrete and other materials has also become simpler....

Five common diamond circular saw blades

2020-12-31

Diamond circular saw blades are the largest sales volume of diamond products, accounting for more than 95% of the total sales of diamond tools. In recent years, China has conducted a lot of research on optimizing the formula of diamond circular saw blades, which has made the sawing function of diamond circular saw blades significantly improved, and the cost of blades has been greatly reduced, making domestic saw blades have strong competitiveness at home and abroad. At present, there are mainly five common circular saw blades on the market. This article gives a detailed introduction to these five different saw blades....

Common process of diamond circular saw blade

2020-09-09

Diamond circular saw blades have different manufacturing methods, and different manufacturing methods allow the saw blade to have different performances after being manufactured. And different processes can make saw blades have different sawing processes. This article introduces four common methods of circular saw blades to let everyone know about the production process of circular saw blades....

Diamond saw blade production process

2020-11-09

Diamond saw blade is a product of the combination of diamond segment and alloy blade body. This article describes the entire saw blade production process from segment production, blade body procurement, saw blade welding, inspection and testing, storage and packaging....

RETURN

RETURN