YOU ARE HERE >

HOME >

DIAMOND SAW BLADE

How to choose a good quality diamond circular saw blade

Publish Date:2021-02-03

In recent years, with the continuous development of the stone industry, especially the vigorous development of natural stone and artificial stone, the diamond tools industry has also experienced explosive growth. Many people don't understand saw blades, so there are some bad businesses that only focus on profit and not quality. Inferior products not only reduce work efficiency, increase costs, but also put operators in danger. So what kind of saw blade is better quality? Through the following five-point detection methods, we can probably understand the pros and cons of the selected saw blades, which is convenient for everyone to compare.

The weight is used to distinguish. Generally speaking, the heavier the saw blade of the same specification and material, the better, especially the large saw blade. The saw blade blade is certain, if the weight differs a lot, then the steel part must be faulty , Either the rigidity is insufficient, or the toughness is not enough, so when selecting a saw blade, load bearing can help us choose a better saw blade.

Listen to the sound and tap the erected saw blade with your fingers. The saw blade with dull sound has a thicker steel body, while the saw blade with crisper sound has poor steel body quality, do not to choose it.

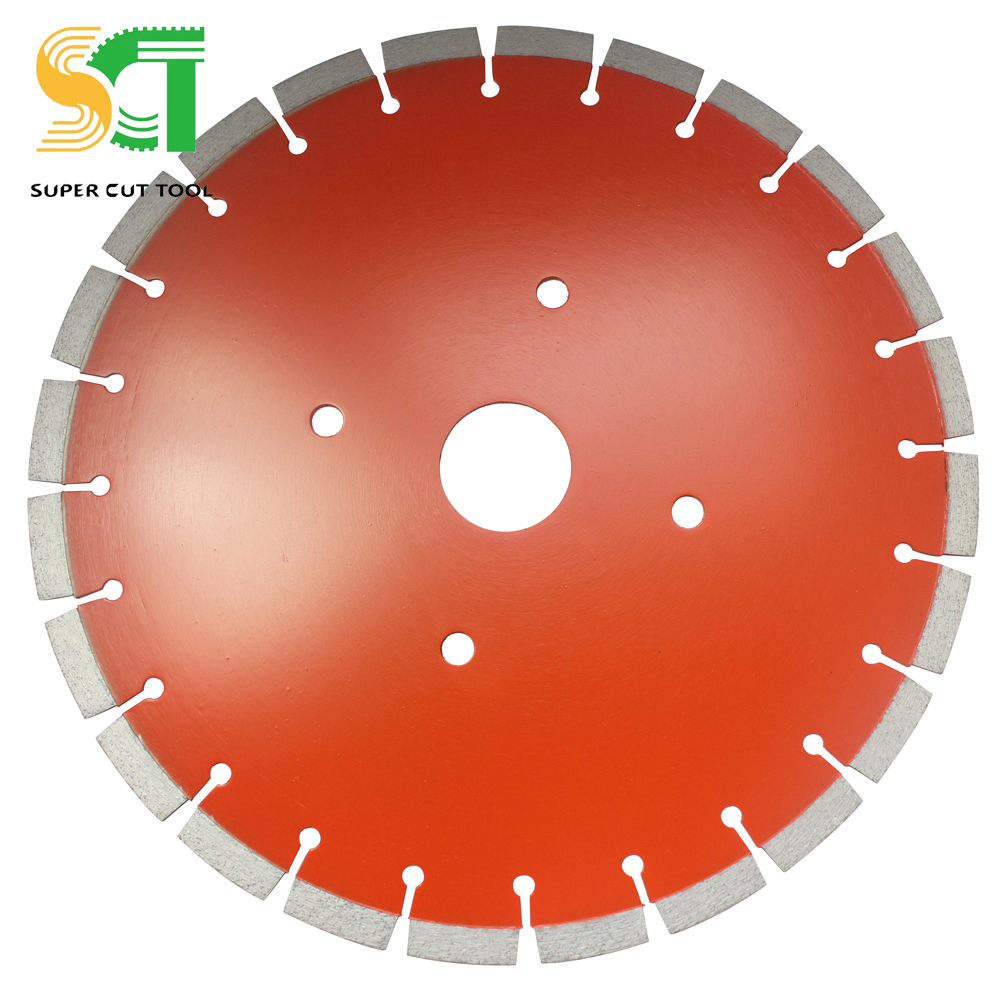

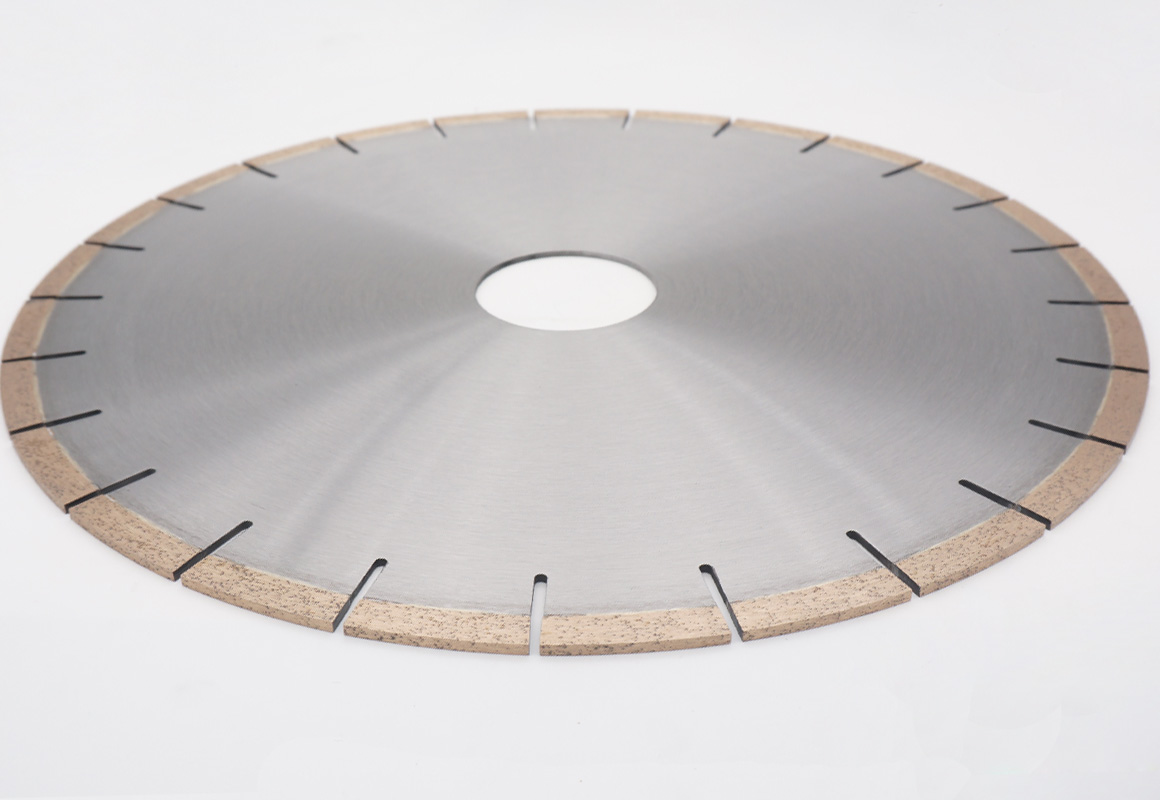

Observe whether the concentration and distribution of the exposed diamond on the marble saw blade segment is uniform. In order to reduce the cost of the inferior saw blade, the method of reducing the diamond content is used to reduce the cost. The process is extremely simple, and the uneven mixing of the diamond causes uneven force surface , After the buyer uses it, not only can’t cut, but also consumes quickly. A good diamond saw blade will see that the diamond distribution of the segment is extremely uniform, and the color and lines of the segment are also very clear. If it is impossible to observe with the naked eye, you can use a magnifying glass or a mobile phone to observe at a macro distance. The higher the diamond concentration, the larger the particles, and the evenly distributed saw blade is a good product.

Look at the color of the blade. The normal granite saw blade has the natural color of iron. The color of the blade is preferably off-white. The inferior granite saw blade is dark because it contains more impurities. For marble saw blades, the color of the blade head is better than golden yellow, while the color of brown is not good. Of course, some manufacturers will choose different binders, and the color of the formula is different, but the overall color is uniform, and it is better for the segment to not blacken.

The cutting effect is also a very important factor. It is mainly manifested in cutting edge smooth without chipping. If the chipping occurs, the saw blade is not very good, especially for cutting some soft stones with uneven cuts, chipped edges or missing corners, it is all caused by poor quality saw blades.

Inferior marble saw blades use inferior diamond powder which low level degree of wear resistance. It make the diamond saw blades not durable, and some manufacturers will the diamond powder from the waste segment. The biggest feature of such a segment is not stable enough, and the diamond is opaque, and seriously carbonization, which leads to problems such as low life and low efficiency of the saw blade.

If the selection of saw blades is still not possible, the quality of diamond saw blades produced by SCT is guaranteed. Higher quality diamonds are used. It is worry-free after sale. Once quality problems occur, SCT will provide a complete compensation plan to provide worry-free services for customers.

Tags:

.jpg)

Installation and use process of diamond circular saw blade

2020-11-09

Diamond saw blades can be used in single blade saw, multiblade saws, infrared bridge cutting machines, hand cutter and other large and medium-sized stone machinery according to their sizes. They can also be used in angle grinders, hand cutting machines etc., the small machines are used in a wide range. This article is mainly based on the application of different saw blades in installation and cutting....

.jpg)

Diamond circular saw blade classification

2020-11-09

Diamond circular saw blades are mainly classified according to size. Generally speaking, they are divided into small-diameter saw blades, medium-diameter saw blades and large saw blades. Small saw blades are also divided according to the shape of the blade, while medium-diameter saw blades can be divided according to the cutting material or the shape of the segment, and the large saw blade is divided according to the purpose. This article introduces the classification of circular saw blades to let you better understand the relevant knowledge of diamond saw blades....

The development of diamond saw blades

2020-09-24

Among all diamond tools, diamond saw blades are the first to appear. With saw blades, cutting becomes simple. Cutting changes the entire world. In terms of decorative materials, wood is not the only choice. Stone, artificial stone, and ceramic tiles are used extensively. In terms of engineering, the cutting of asphalt, reinforced concrete and other materials has also become simpler....

Five common diamond circular saw blades

2020-12-31

Diamond circular saw blades are the largest sales volume of diamond products, accounting for more than 95% of the total sales of diamond tools. In recent years, China has conducted a lot of research on optimizing the formula of diamond circular saw blades, which has made the sawing function of diamond circular saw blades significantly improved, and the cost of blades has been greatly reduced, making domestic saw blades have strong competitiveness at home and abroad. At present, there are mainly five common circular saw blades on the market. This article gives a detailed introduction to these five different saw blades....

Common process of diamond circular saw blade

2020-09-09

Diamond circular saw blades have different manufacturing methods, and different manufacturing methods allow the saw blade to have different performances after being manufactured. And different processes can make saw blades have different sawing processes. This article introduces four common methods of circular saw blades to let everyone know about the production process of circular saw blades....

Diamond saw blade production process

2020-11-09

Diamond saw blade is a product of the combination of diamond segment and alloy blade body. This article describes the entire saw blade production process from segment production, blade body procurement, saw blade welding, inspection and testing, storage and packaging....

RETURN

RETURN