YOU ARE HERE >

HOME >

DIAMOND SAW BLADE

The development of diamond saw blades

Publish Date:2020-09-24

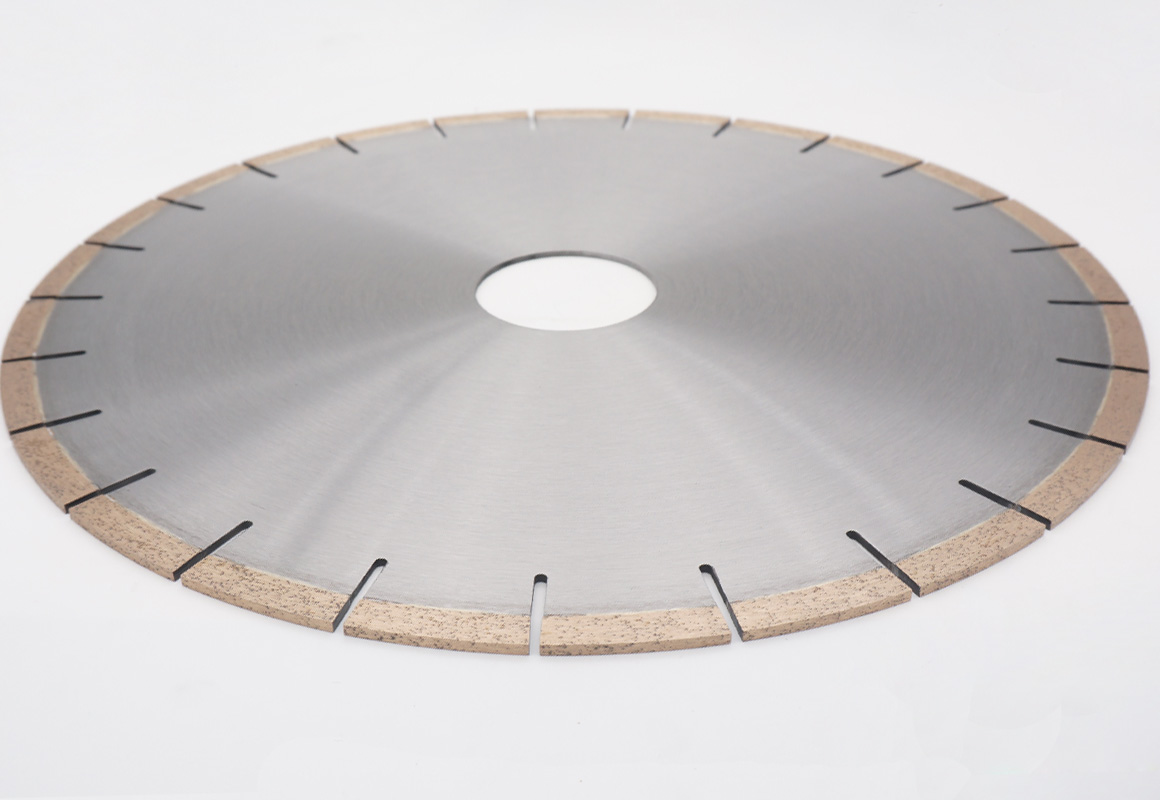

In 1885, in the development of modern science and technology, the first diamond saw blade was manufactured in a small town in France. Because the artificial diamond technology did not exist at that time, a large number of natural diamonds were embedded in this blade. On the saw blade, the high price of diamonds makes this kind of saw blade a luxury item, and it is not widely used, but it is also such a saw blade that makes people see the possibility of fast sawing. In the following decades, people have continuously studied to reduce the cost of diamond saw blades and continuously improve their efficiency. Finally, at the end of the 20th century, European diamond saw blades have already possessed the characteristics of modern saw blades and are also the embryonic form of modern diamond saw blades.The progress of material technology is the reason for the continuous breakthrough and development of diamond saw blades. The continuous innovation of metal bond, the continuous research and development of the fusion of metal materials, and the continuous optimization of the particle size of diamond powder are the reasons for the development of diamond saw blades. The performance is essentially the root cause of the improvement. Science and technology is the primary productive force, and it is also applicable in the diamond industry.

The real reduction in the threshold of diamond saw blades is that in the 1970s, synthetic diamonds began to replace natural diamonds in large quantities. The mass production of synthetic diamonds allowed natural diamonds to be completely separated from the industry, thereby greatly reducing the production cost, and the controllability of the particle size and structure of synthetic diamond also improves the stability of diamond powder. In addition, in powder metallurgy, the birth of laser welding technology allows the segment and the blade body to be closely combined, which not only reduces the cost of diamond saw blades, but also improves the performance of diamond saw blades to another high stage.

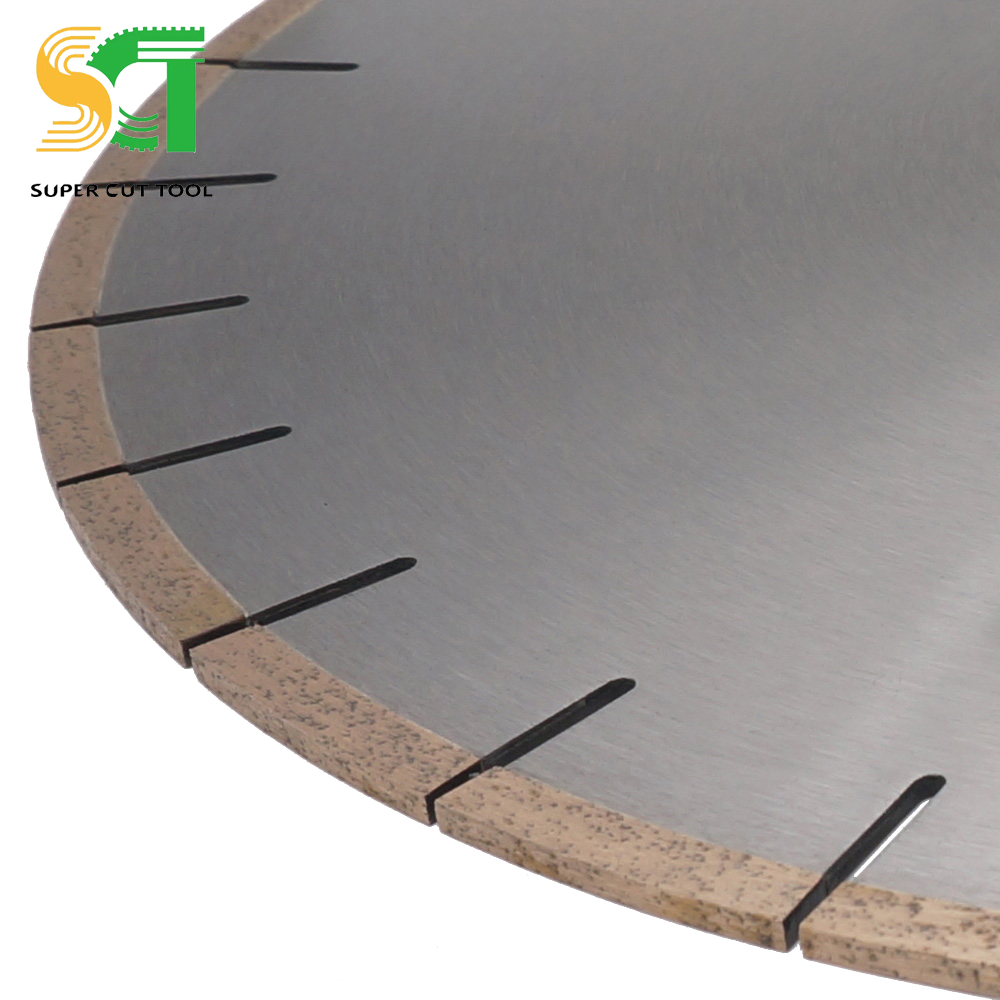

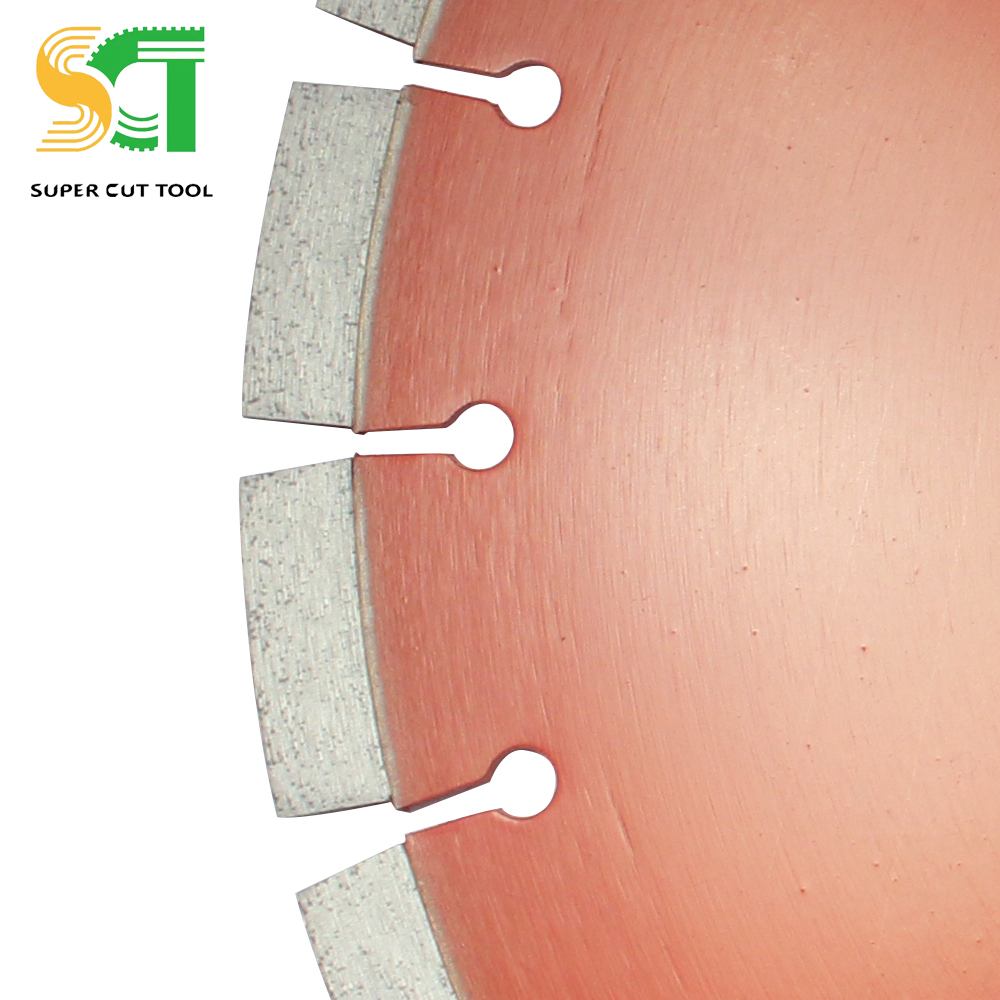

With the improvement of the diamond saw blades performance, diamond saw blades have gradually transitioned from the earliest cutting jade, wood, aluminum and other materials to the field of stone sawing processing. In this transition process, diamond technology and metallurgical technology are the core factors. The most fundamental factor is the continuous improvement of the hardness of the diamond saw blade segment. There is an old Chinese saying that The stones of those hills may be used to polish gems. Hardness directly determines the cutting ability of diamond saw blades. At present, the hardness of diamond blades can reach Mohs hardness 10-11, while the Mohs hardness of stone is about 6-8. In this way, the use hardness to overcome hardness is the cutting principle of diamond saw blades.

Generally speaking, the Mohs hardness largely determines the segment sharpness and the life. However, in practical applications, there will be two bad situations for the cutter head with too high Mohs hardness. First, The diamond loss exceeds the consumption of the segment bond, then such a saw blade will not be able to cut, the blade body will be distorted, the diamond saw blade will be damaged, or the slab will be broken. In more serious cases, the saw blade will rise the cutting machine main shaft that causes mechanical damage. Second, the diamond loss is lower than the loss of the segment bond, so it is easy to peel off the diamond powder.

According to the quality of diamond saw blades, there are mainly super-class Italian and Korean saw blades. They use good materials and advanced technology, but they are expensive. The second batch is saw blades produced by Chinese manufacturers, occupying stone with cost-effectiveness. The third batch of saw blades for developing countries, such as saw blades produced in India, Indonesia and other countries, are mainly low-priced products

Tags:

blades

.jpg)

Installation and use process of diamond circular saw blade

2020-11-09

Diamond saw blades can be used in single blade saw, multiblade saws, infrared bridge cutting machines, hand cutter and other large and medium-sized stone machinery according to their sizes. They can also be used in angle grinders, hand cutting machines etc., the small machines are used in a wide range. This article is mainly based on the application of different saw blades in installation and cutting....

.jpg)

Diamond circular saw blade classification

2020-11-09

Diamond circular saw blades are mainly classified according to size. Generally speaking, they are divided into small-diameter saw blades, medium-diameter saw blades and large saw blades. Small saw blades are also divided according to the shape of the blade, while medium-diameter saw blades can be divided according to the cutting material or the shape of the segment, and the large saw blade is divided according to the purpose. This article introduces the classification of circular saw blades to let you better understand the relevant knowledge of diamond saw blades....

The development of diamond saw blades

2020-09-24

Among all diamond tools, diamond saw blades are the first to appear. With saw blades, cutting becomes simple. Cutting changes the entire world. In terms of decorative materials, wood is not the only choice. Stone, artificial stone, and ceramic tiles are used extensively. In terms of engineering, the cutting of asphalt, reinforced concrete and other materials has also become simpler....

Five common diamond circular saw blades

2020-12-31

Diamond circular saw blades are the largest sales volume of diamond products, accounting for more than 95% of the total sales of diamond tools. In recent years, China has conducted a lot of research on optimizing the formula of diamond circular saw blades, which has made the sawing function of diamond circular saw blades significantly improved, and the cost of blades has been greatly reduced, making domestic saw blades have strong competitiveness at home and abroad. At present, there are mainly five common circular saw blades on the market. This article gives a detailed introduction to these five different saw blades....

Common process of diamond circular saw blade

2020-09-09

Diamond circular saw blades have different manufacturing methods, and different manufacturing methods allow the saw blade to have different performances after being manufactured. And different processes can make saw blades have different sawing processes. This article introduces four common methods of circular saw blades to let everyone know about the production process of circular saw blades....

Diamond saw blade production process

2020-11-09

Diamond saw blade is a product of the combination of diamond segment and alloy blade body. This article describes the entire saw blade production process from segment production, blade body procurement, saw blade welding, inspection and testing, storage and packaging....

RETURN

RETURN