YOU ARE HERE >

HOME >

DIAMOND SAW BLADE

Classification of diamond circular saw blades

Publish Date:2020-09-09

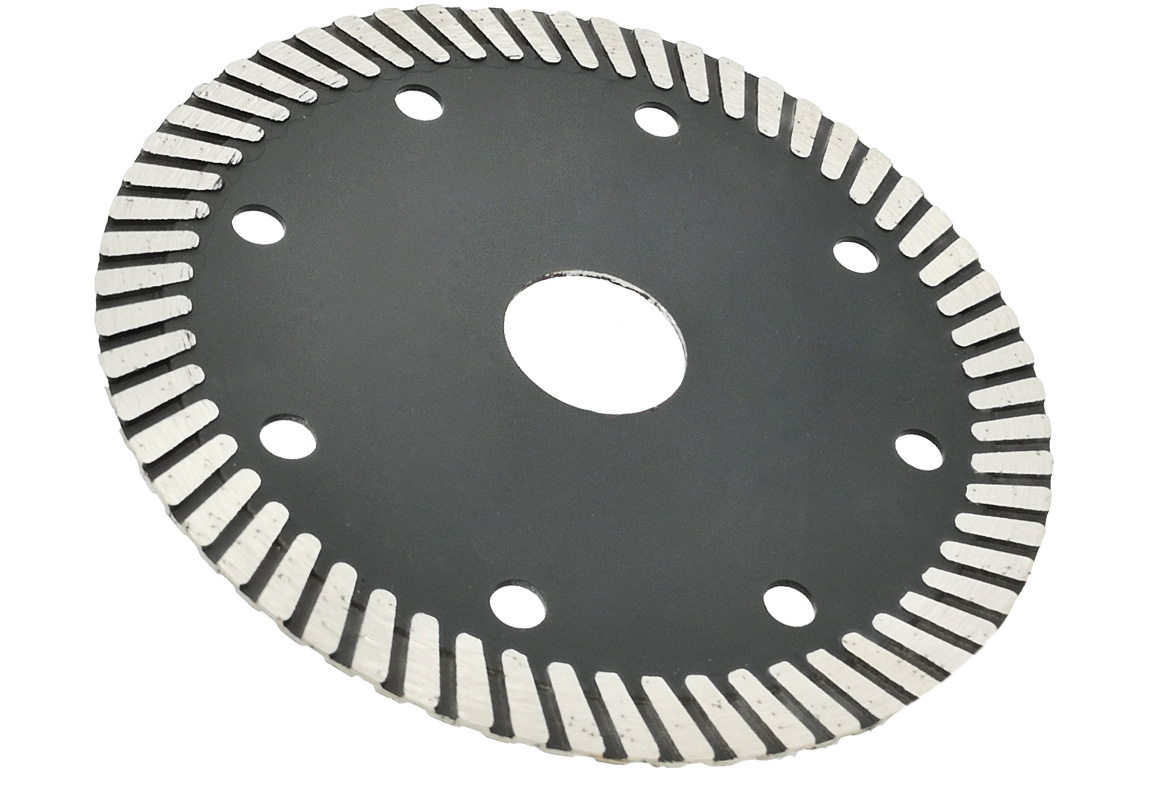

Circular saw blade is the most commonly used sawing tool. Its diameter spans from Dia:105mm to 4800mm, and its thickness ranges from 0.1mm to 15mm. It has a wide range of uses, and its manufacturing methods are many and difficult. There are three main types of circular saw blades:(1) The segmental saw blade includes the cold press. Sintered (Dia: 105mm-450 dry cutter, and 350mm-4800mm marble and granite cutting blades manufactured by hot pressing and welding are the most versatile. Diamond sintered cutting blades, also known as tooth cutting blades. It is characterized by sharp cutting and long life, mainly used for cutting granite, sandstone, concrete, bricks, etc. According to the process, it can be divided into two types: sintered and hot-pressed sintered. The latter has a longer service life and safer. Welding according to different segment. The methods are divided into high-frequency welding and laser welding. There are also high-temperature framing weld methods in some countries and regions. Generally speaking, high-frequency welding is more suitable for stone cutting, while diamond laser welding professional cutting blades are used for concrete and asphalt roads, Refractory brick, bricks, building blocks, etc. Because laser welding strength will not decrease under cutting conditions without coolant, so it is suitable for field operations.

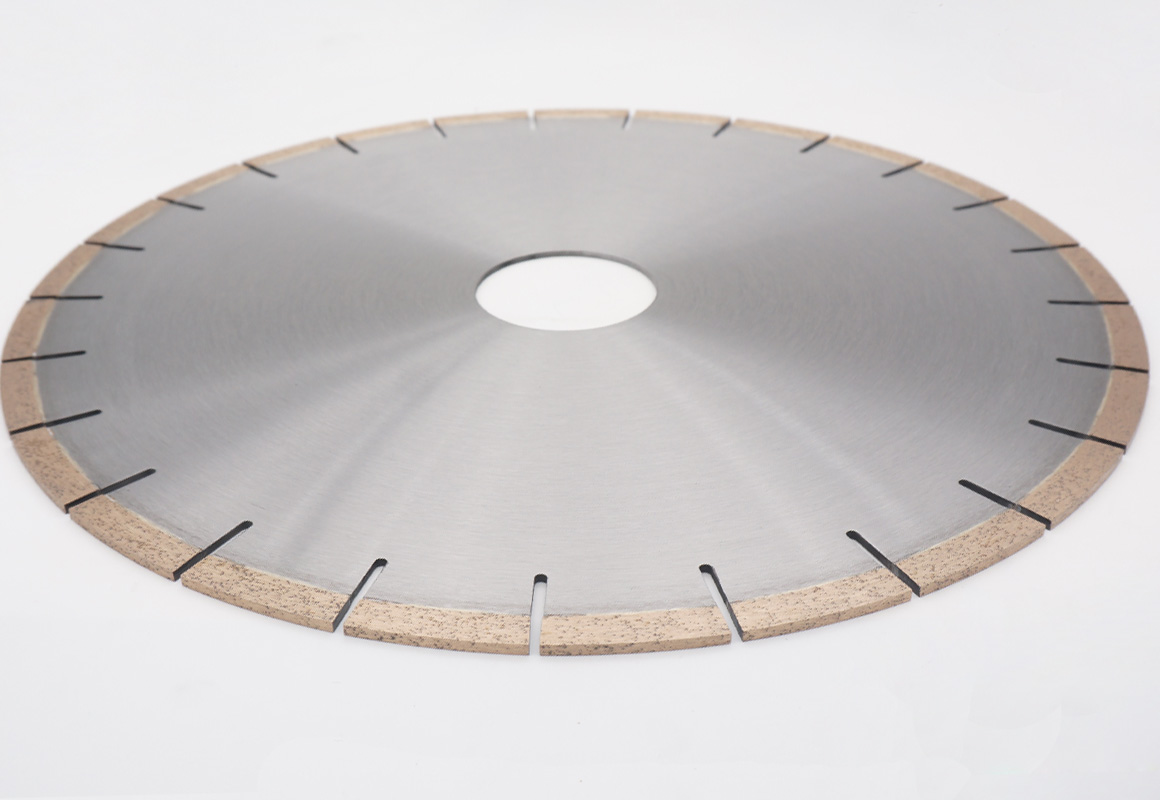

(2) Continuous rim saw blade. generally manufactured by cold pressing or hot pressing methods, including jade carving saw blades for jade cutting, dry and wet saw blade for other purposes. Diamond continuous rim cutting blade is also called diamond wet saw blade. Because the diamond blade is continuous, the cooling effect of cutting is not good. Generally, it is cut under the condition of adding water or coolant. This kind of cutting blade is generally more suitable for cutting and fragile Marble, ceramic tile, glass, quartz and other extremely brittle materials. Of course, it can also be used to cut granite, concrete, etc.

(3) The inner circle cutting disc is mainly used for cutting precious materials such as monocrystalline silicon. In order to save precious materials, its thickness is required to be very thin (b= 0.1-0.5mm), and it is generally manufactured by plating.

Tags:

.jpg)

Installation and use process of diamond circular saw blade

2020-11-09

Diamond saw blades can be used in single blade saw, multiblade saws, infrared bridge cutting machines, hand cutter and other large and medium-sized stone machinery according to their sizes. They can also be used in angle grinders, hand cutting machines etc., the small machines are used in a wide range. This article is mainly based on the application of different saw blades in installation and cutting....

.jpg)

Diamond circular saw blade classification

2020-11-09

Diamond circular saw blades are mainly classified according to size. Generally speaking, they are divided into small-diameter saw blades, medium-diameter saw blades and large saw blades. Small saw blades are also divided according to the shape of the blade, while medium-diameter saw blades can be divided according to the cutting material or the shape of the segment, and the large saw blade is divided according to the purpose. This article introduces the classification of circular saw blades to let you better understand the relevant knowledge of diamond saw blades....

The development of diamond saw blades

2020-09-24

Among all diamond tools, diamond saw blades are the first to appear. With saw blades, cutting becomes simple. Cutting changes the entire world. In terms of decorative materials, wood is not the only choice. Stone, artificial stone, and ceramic tiles are used extensively. In terms of engineering, the cutting of asphalt, reinforced concrete and other materials has also become simpler....

Five common diamond circular saw blades

2020-12-31

Diamond circular saw blades are the largest sales volume of diamond products, accounting for more than 95% of the total sales of diamond tools. In recent years, China has conducted a lot of research on optimizing the formula of diamond circular saw blades, which has made the sawing function of diamond circular saw blades significantly improved, and the cost of blades has been greatly reduced, making domestic saw blades have strong competitiveness at home and abroad. At present, there are mainly five common circular saw blades on the market. This article gives a detailed introduction to these five different saw blades....

Common process of diamond circular saw blade

2020-09-09

Diamond circular saw blades have different manufacturing methods, and different manufacturing methods allow the saw blade to have different performances after being manufactured. And different processes can make saw blades have different sawing processes. This article introduces four common methods of circular saw blades to let everyone know about the production process of circular saw blades....

Diamond saw blade production process

2020-11-09

Diamond saw blade is a product of the combination of diamond segment and alloy blade body. This article describes the entire saw blade production process from segment production, blade body procurement, saw blade welding, inspection and testing, storage and packaging....

RETURN

RETURN