YOU ARE HERE >

HOME >

DIAMOND SAW BLADE

How to choose a diamond saw blade

Publish Date:2020-11-09

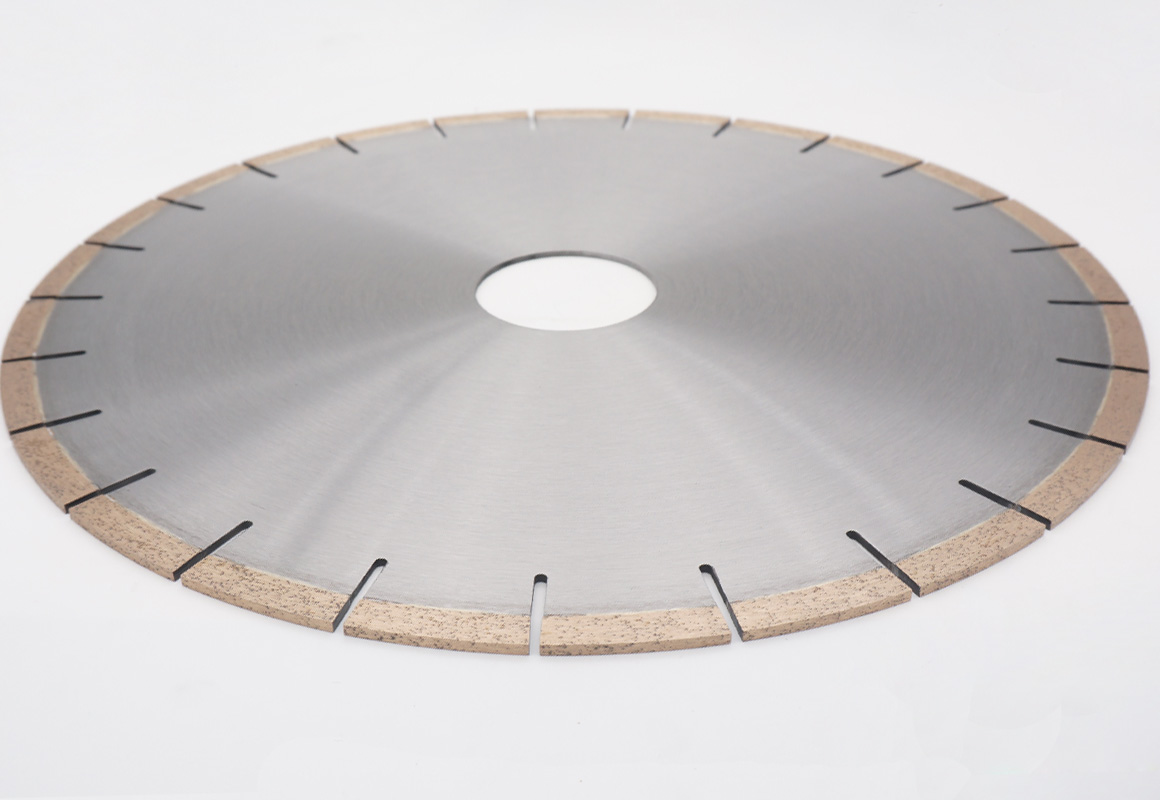

Diamond saw blades are industrial products. Unlike ordinary products, it is not easy to see whether they are good or bad in appearance. In fact, this is also true. Many saw blades have poor quality control, but the quality of the selected segment is better, although it looks ugly, but it is very practical to use. Although the decisive factor of the saw blade is the segment, how to choose the saw blade must be judged through some specific details.In the selection process, we mainly check the following aspects. Through simple visual observation, we can simply make a judgment on the quality of the saw blade.

1. First look at whether the segment on the diamond saw blade is in the same straight line

If the segment is not on the same straight line, it means that the size of the segment is irregular, some may be wide and some narrow, which will cause unstable and affect the quality of the saw blade.

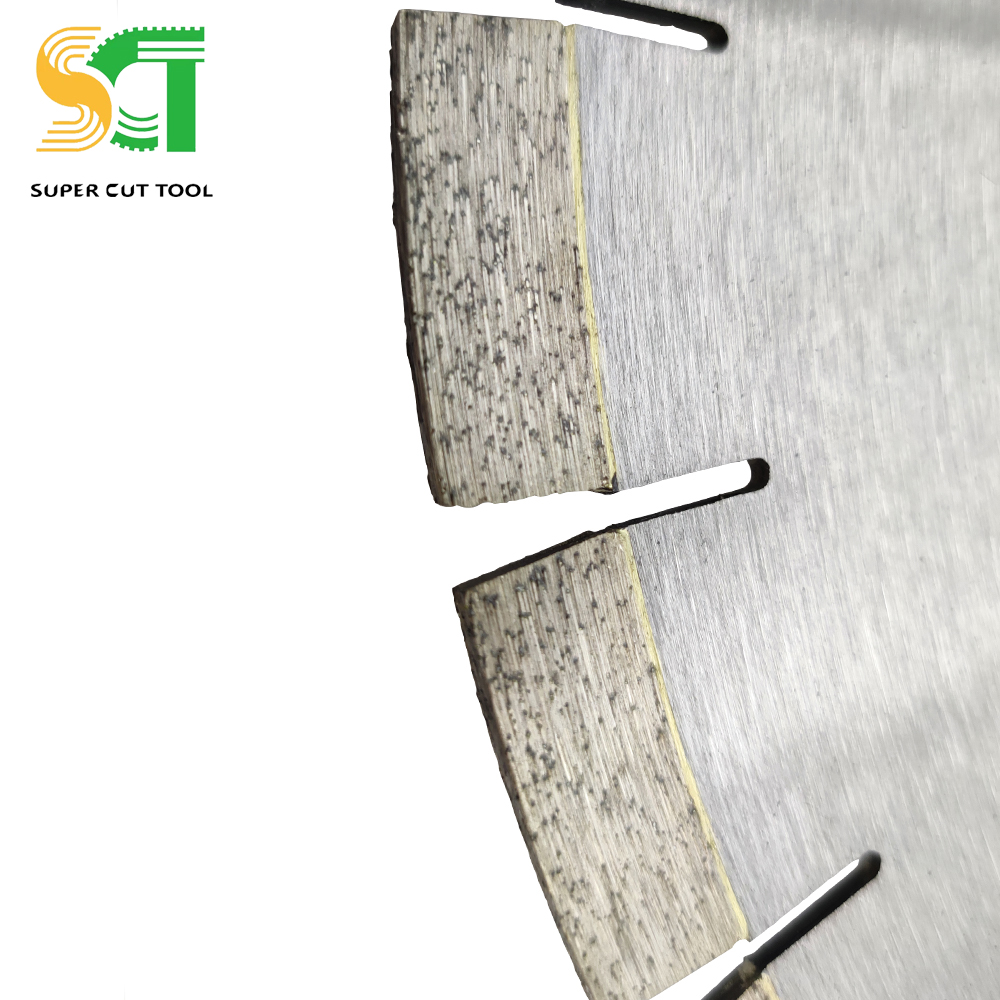

2. Observe whether the weld and the steel blade body are tightly welded

There will be a welding seam and the base body after segment welding on steel blade body. If the arc-shaped surface of the segment is completely fused with the blade body, there will be no gap. The gap indicates that the segment on the diamond saw blade and the blade body are not completely fused. This is because the curved surface at the bottom of the segment is unevenly ground.

3. Measure the weight of the saw blade

The heavier and thicker the diamond saw blade is, the better, because if the saw blade is heavy, the greater the inertial force during cutting, the more stable the cutting performance. Generally speaking, 350mm diamond saw blade should be about 2 kg, 400mm diamond saw blade should be about 3 kg.

4. Check the hardness of the blade body

The higher the hardness of the blade body, the less likely to be deformed. Therefore, whether the blade body hardness reaches the standard directly affects the quality of the saw blade during welding or cutting. It is a good blade for high temperature welding without deformation, and without deformation under force majeure conditions.

5. Test the toughness of the blade body

There are many blade body materials for the saw blade. At present, high-speed steel and alloy steel are the best choices, but the blade body must be tough. Although it cannot be judged directly with the naked eye, it can be considered from the parameters of the saw blade. If the toughness of the blade body is strong, the impact resistance and bending resistance will be better during the cutting process, thereby extending the service life of the substrate.

When selecting a saw blade, you can test the contents of these 5 aspects separately, and compare the above aspects to verify whether the selected saw blade is a high-quality and durable diamond saw blade.

Tags:

.jpg)

Installation and use process of diamond circular saw blade

2020-11-09

Diamond saw blades can be used in single blade saw, multiblade saws, infrared bridge cutting machines, hand cutter and other large and medium-sized stone machinery according to their sizes. They can also be used in angle grinders, hand cutting machines etc., the small machines are used in a wide range. This article is mainly based on the application of different saw blades in installation and cutting....

.jpg)

Diamond circular saw blade classification

2020-11-09

Diamond circular saw blades are mainly classified according to size. Generally speaking, they are divided into small-diameter saw blades, medium-diameter saw blades and large saw blades. Small saw blades are also divided according to the shape of the blade, while medium-diameter saw blades can be divided according to the cutting material or the shape of the segment, and the large saw blade is divided according to the purpose. This article introduces the classification of circular saw blades to let you better understand the relevant knowledge of diamond saw blades....

The development of diamond saw blades

2020-09-24

Among all diamond tools, diamond saw blades are the first to appear. With saw blades, cutting becomes simple. Cutting changes the entire world. In terms of decorative materials, wood is not the only choice. Stone, artificial stone, and ceramic tiles are used extensively. In terms of engineering, the cutting of asphalt, reinforced concrete and other materials has also become simpler....

Five common diamond circular saw blades

2020-12-31

Diamond circular saw blades are the largest sales volume of diamond products, accounting for more than 95% of the total sales of diamond tools. In recent years, China has conducted a lot of research on optimizing the formula of diamond circular saw blades, which has made the sawing function of diamond circular saw blades significantly improved, and the cost of blades has been greatly reduced, making domestic saw blades have strong competitiveness at home and abroad. At present, there are mainly five common circular saw blades on the market. This article gives a detailed introduction to these five different saw blades....

Common process of diamond circular saw blade

2020-09-09

Diamond circular saw blades have different manufacturing methods, and different manufacturing methods allow the saw blade to have different performances after being manufactured. And different processes can make saw blades have different sawing processes. This article introduces four common methods of circular saw blades to let everyone know about the production process of circular saw blades....

Diamond saw blade production process

2020-11-09

Diamond saw blade is a product of the combination of diamond segment and alloy blade body. This article describes the entire saw blade production process from segment production, blade body procurement, saw blade welding, inspection and testing, storage and packaging....

RETURN

RETURN