YOU ARE HERE >

HOME >

DIAMOND SAW BLADE

How to judge the quality of diamond saw blades

Publish Date:2020-11-09

Diamond saw blades are mainly used to cut concrete, refractory materials, stone, ceramics, etc hard and brittle materials. In the process of use, the sharpness and the life of diamond saw blades are different. What causes it? Usually many people only know blade quality after they have tried it. Today, Super Cut Tool Co., Ltd saw blade production engineers will analyze how to distinguish the quality of the diamond saw blade in the simplest way.

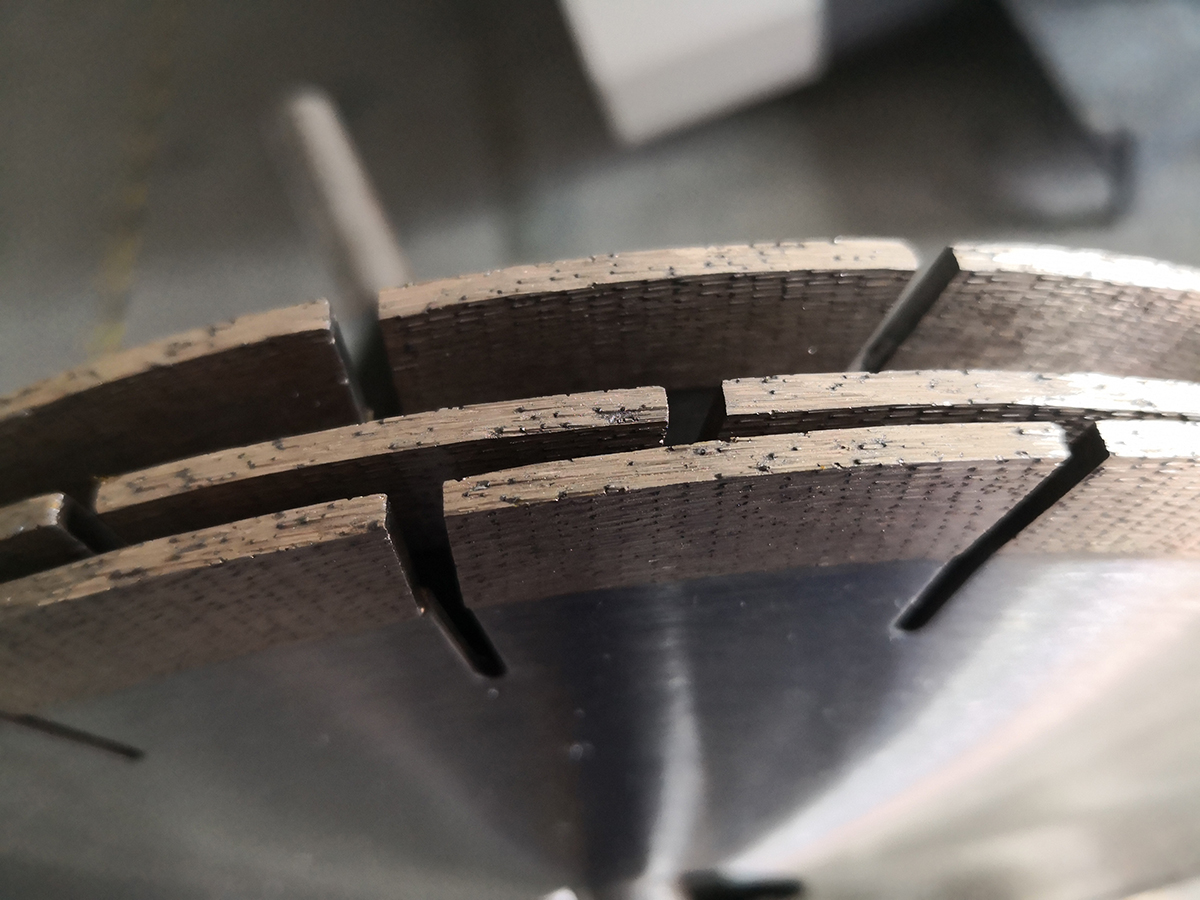

1. Observe the segment, mainly to observe the exposed diamond and observe its concentration and distribution. The content of diamond in a good diamond saw blade will not be too small, but not too much. Uniform dispersion is the best. How to call it evenly distributed? After the saw blade is opened, we can observe that if the diamond on the saw blade shows a uniform meteor trailing effect, and the trailing will be 0.5-1 cm long, then such a blade is very good. If the content of diamond is too small, there will be very little tailing. If too much diamond is put in, the bond will not hold the diamond enough, so tailing will not happen. If the segment is good, the saw blade is basically not too bad.

2. Welding seam, Welding seam directly affects chip removal and heat dissipation, and severely even causes the segment to fall off. Therefore, it is very important to observe whether the welding seam is complete and tidy. If the welding seam is not continuous and the edge of the segment is not vertically aligned with the steel blade body slot, the segment will fall off and break. If you cannot judge from experience, it is best to purchase a horizontal clamp. When the clamp is fixed on the segment and the steel blade base, the angle between the segment and the saw blade is automatically judged, and the weld strength can also be tested.

3. Hold the saw blade in your hand and observe whether the diamond segment is aligned with the blade steel body on the horizontal plane. If the segment is not aligned, the segment will collapse or even fall off during use. To measure the welding seam, and here is to measure the level.

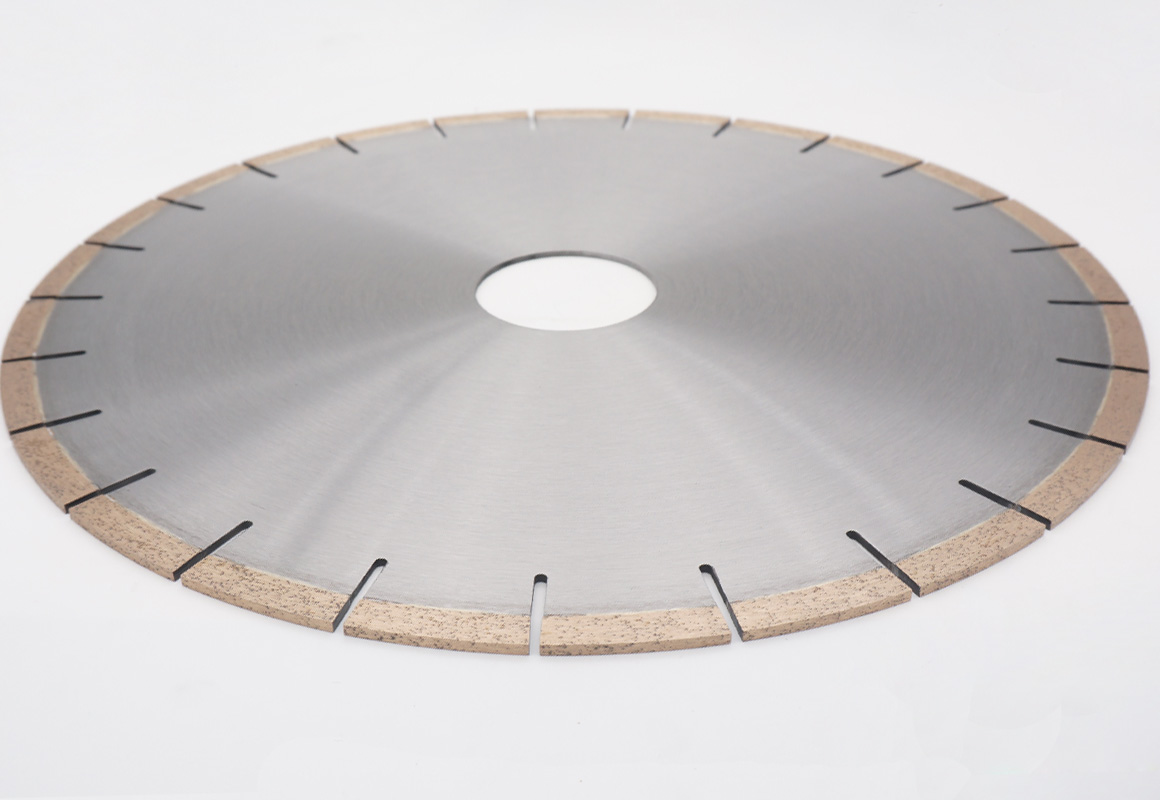

4. Compare the thickness of the segment and the blade steel body. Take a 350mm granite saw blade as an example. Under normal circumstances, the segment is about 1mm thicker than blade steel body. The 350mm marble saw blade segment will be about 0.8mm thicker than the blade steel body. The reason for this design is to prevent damage to the blade steel body and increase the service life of the saw blade. There is a contradiction between the sharpness and wear resistance of the saw blade. The suggestion is that when the life of the saw blade reaches the expected target and the sharpness is moderate, do not ask for an increase in the life. Because the external environment, such as the cutting machine, the operation of the worker, the hardness of the stone, etc., will change at any time, and once the external environment changes, the original wear-resistant saw blade may not necessarily be usable.

In fact, there are still a lot of test data for the quality of the saw blade, such as the toughness of the blade steel body, the fracture resistance, the elasticity and the rigidity, etc. In terms of the segment, it is also necessary to observe the solder joint, whether it is a copper solder or a silver solder. Of course, these are simple ways of judging the quality of the saw blade at present, and more accurate data still have to wait until the cutting efficiency and service life of the saw blade in the cutting process.

Tags:

.jpg)

Installation and use process of diamond circular saw blade

2020-11-09

Diamond saw blades can be used in single blade saw, multiblade saws, infrared bridge cutting machines, hand cutter and other large and medium-sized stone machinery according to their sizes. They can also be used in angle grinders, hand cutting machines etc., the small machines are used in a wide range. This article is mainly based on the application of different saw blades in installation and cutting....

.jpg)

Diamond circular saw blade classification

2020-11-09

Diamond circular saw blades are mainly classified according to size. Generally speaking, they are divided into small-diameter saw blades, medium-diameter saw blades and large saw blades. Small saw blades are also divided according to the shape of the blade, while medium-diameter saw blades can be divided according to the cutting material or the shape of the segment, and the large saw blade is divided according to the purpose. This article introduces the classification of circular saw blades to let you better understand the relevant knowledge of diamond saw blades....

The development of diamond saw blades

2020-09-24

Among all diamond tools, diamond saw blades are the first to appear. With saw blades, cutting becomes simple. Cutting changes the entire world. In terms of decorative materials, wood is not the only choice. Stone, artificial stone, and ceramic tiles are used extensively. In terms of engineering, the cutting of asphalt, reinforced concrete and other materials has also become simpler....

Five common diamond circular saw blades

2020-12-31

Diamond circular saw blades are the largest sales volume of diamond products, accounting for more than 95% of the total sales of diamond tools. In recent years, China has conducted a lot of research on optimizing the formula of diamond circular saw blades, which has made the sawing function of diamond circular saw blades significantly improved, and the cost of blades has been greatly reduced, making domestic saw blades have strong competitiveness at home and abroad. At present, there are mainly five common circular saw blades on the market. This article gives a detailed introduction to these five different saw blades....

Common process of diamond circular saw blade

2020-09-09

Diamond circular saw blades have different manufacturing methods, and different manufacturing methods allow the saw blade to have different performances after being manufactured. And different processes can make saw blades have different sawing processes. This article introduces four common methods of circular saw blades to let everyone know about the production process of circular saw blades....

Diamond saw blade production process

2020-11-09

Diamond saw blade is a product of the combination of diamond segment and alloy blade body. This article describes the entire saw blade production process from segment production, blade body procurement, saw blade welding, inspection and testing, storage and packaging....

RETURN

RETURN