YOU ARE HERE >

HOME >

DIAMOND SAW BLADE

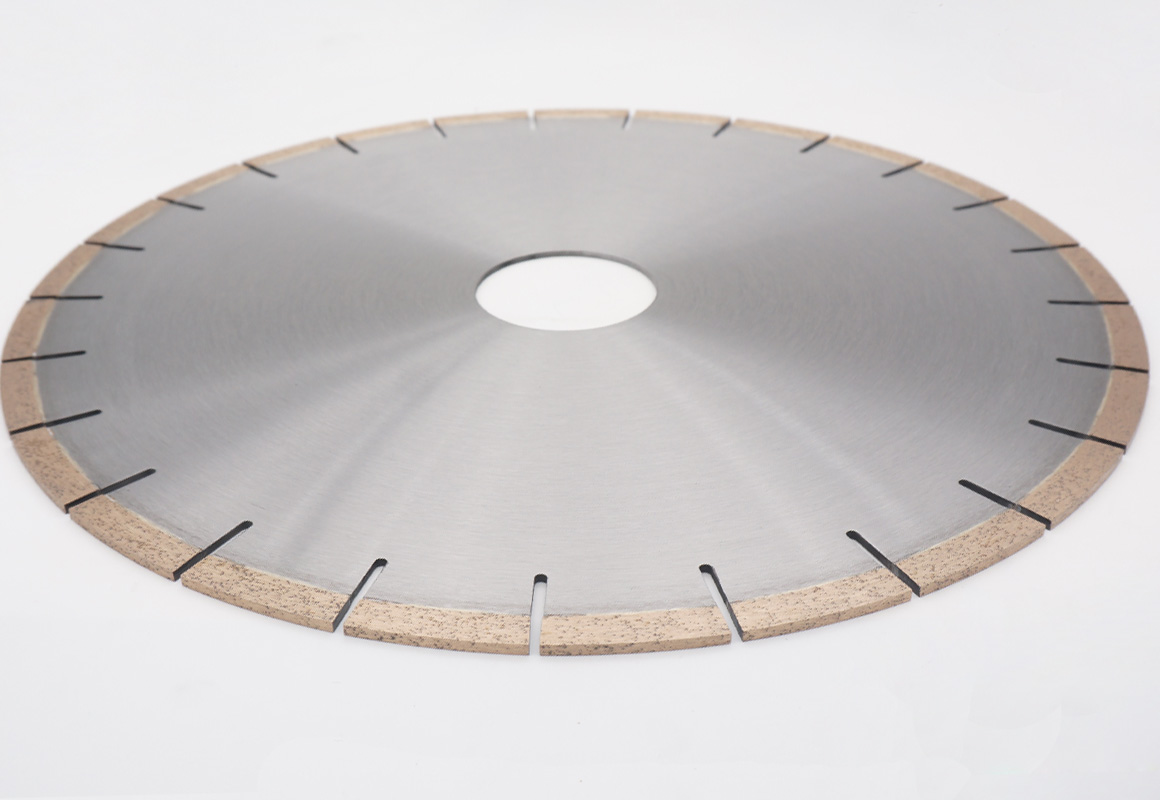

Common problems and treatment of stone saw blade cutting process

Publish Date:2020-09-24

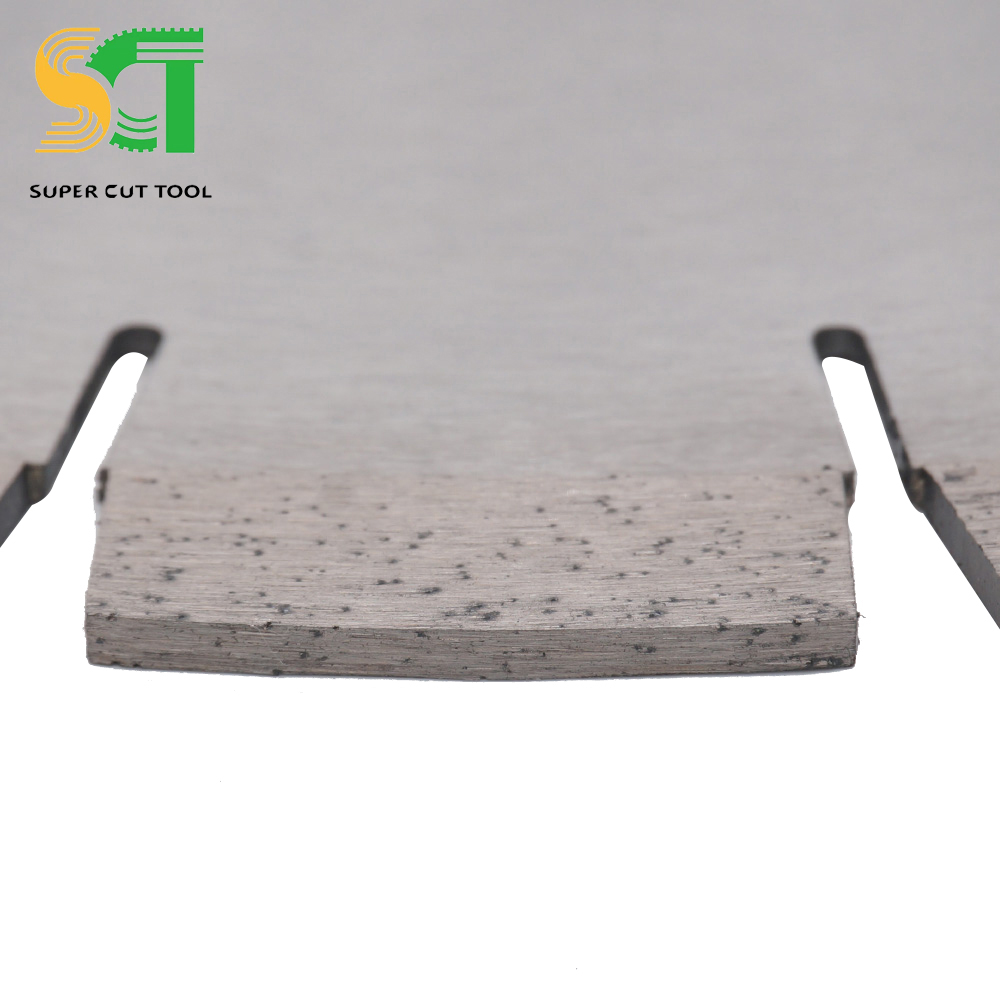

In the process of cutting stone, diamond saw blades will have various problems. Below we have listed the eight most common problems and their treatment methods. I hope it will help to you.1. Wear at the joint between the blade body and segment

Reason: The material to be cut is very wear-resistant, and the cutting debris can not be discharged in time.

Solution: Use protective teeth at special positions on the blade body, and use a higher pressure cooling water flow to enhance the chip removal effect. In addition, the use of M-shaped and W-shaped segment can also improve this situation.

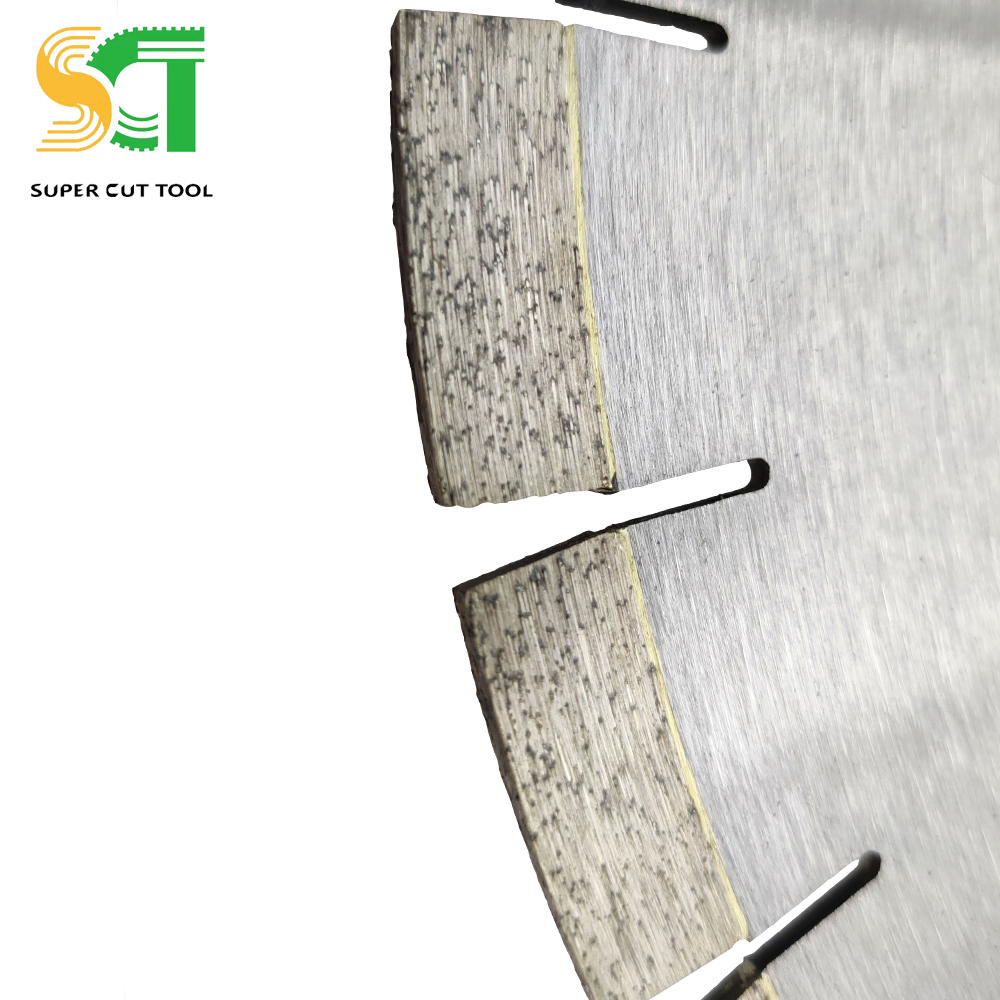

2. Both sides of the segment wear unevenly and partly wear

Reasons: There are two reasons, the first one: the saw blade is cutting obliquely; the second: the water volume on both sides is different, and the water volume on one side is insufficient.

Solution: The respective response methods are: the first: check the tilt of the saw blade; the second: check the cooling water system, adjust the direction of the water pipe and waterway.

3. Saw blade out of circle

Reason: The shaft is worn and the gap between the center hole of the saw blade and the spindle is large or the installation is incorrect.

Solution: Replace the worn shaft or repair the center hole.

4. Saw blade swing

Reasons: There are three reasons: the first one: the debris of the cut material caught in the saw gap causes uneven force on the blade body; the second one: the flange diameter is too small or the flange diameters on both sides are not consistent; the third: There is foreign matter between the saw blade and the flange; the saw blade is not installed correctly.

Solution: Separate solutions: The first: clean up debris and enhance the chip removal effect; the second: adjust or replace the flange; the third: install the saw blade correctly according to the instructions.

5. Segment broken

Reason: There are two reasons: the first one: the segment bond is too hard; the second one: the feeding speed of the saw blade is too fast.

Solution: Separate solutions: The first: select a softer bond for the segment according to the material to be cut; the second: reduce the feed speed of the saw blade.

6. The cutter head wears out too quickly

Reasons: There are four reasons: first: the segment bond is too soft (for the material to be cut); second: insufficient cooling water; third: insufficient power due to loose transmission belt or low voltage or improper speed; Four: The saw blade is not perpendicular to the material being cut.

Solution: Corresponding solution: The first: select a softer bond for the segment according to the material to be cut; the second: check the cooling water system to ensure the normal operation of the water pump; ensure the power supply voltage; the third: check The main shaft flange ensures the verticality of the saw blade and the equipment; the fourth type: check the speed of the saw blade and measure the verticality of the saw blade.

7. The saw blade has segment drop

Reasons: There are five reasons: the first one is during the cutting process, the stone moves to twist the segment; the second one is the segment is hit hard; the third one is flange wears out and can not fix the saw blade, which causes the saw blade to twist; the fourth one is the saw blade is out of circle caused by the spindle wear The saw blade is subject to greater impact; the fifth one is overheating; the saw blade is subject to violent impact.

Solution: Corresponding solutions: The first: firmly fix the stone; the second: replace the flanges on both sides; the third: replace the worn spindle; the fourth: check the cooling water; Five types: Avoid hitting the saw blade when moving machinery or stones.

8. Blunt saw blade can not cut

Reasons: There are three reasons: the first: the matrix bond of the diamond segment is too hard; the second: insufficient power which can not make the saw blade cut normally, the saw blade is not applied enough cutting pressure; third: the saw blade line speed is too high.

Solution: The first method is to use a softer bond diamond segment; the second method: check the transmission belt, voltage and motor; make sure to use sufficient and not too large cutting pressure; the third method: select the matching linear speed according the machine manual.

Tags:

blades

.jpg)

Installation and use process of diamond circular saw blade

2020-11-09

Diamond saw blades can be used in single blade saw, multiblade saws, infrared bridge cutting machines, hand cutter and other large and medium-sized stone machinery according to their sizes. They can also be used in angle grinders, hand cutting machines etc., the small machines are used in a wide range. This article is mainly based on the application of different saw blades in installation and cutting....

.jpg)

Diamond circular saw blade classification

2020-11-09

Diamond circular saw blades are mainly classified according to size. Generally speaking, they are divided into small-diameter saw blades, medium-diameter saw blades and large saw blades. Small saw blades are also divided according to the shape of the blade, while medium-diameter saw blades can be divided according to the cutting material or the shape of the segment, and the large saw blade is divided according to the purpose. This article introduces the classification of circular saw blades to let you better understand the relevant knowledge of diamond saw blades....

The development of diamond saw blades

2020-09-24

Among all diamond tools, diamond saw blades are the first to appear. With saw blades, cutting becomes simple. Cutting changes the entire world. In terms of decorative materials, wood is not the only choice. Stone, artificial stone, and ceramic tiles are used extensively. In terms of engineering, the cutting of asphalt, reinforced concrete and other materials has also become simpler....

Five common diamond circular saw blades

2020-12-31

Diamond circular saw blades are the largest sales volume of diamond products, accounting for more than 95% of the total sales of diamond tools. In recent years, China has conducted a lot of research on optimizing the formula of diamond circular saw blades, which has made the sawing function of diamond circular saw blades significantly improved, and the cost of blades has been greatly reduced, making domestic saw blades have strong competitiveness at home and abroad. At present, there are mainly five common circular saw blades on the market. This article gives a detailed introduction to these five different saw blades....

Common process of diamond circular saw blade

2020-09-09

Diamond circular saw blades have different manufacturing methods, and different manufacturing methods allow the saw blade to have different performances after being manufactured. And different processes can make saw blades have different sawing processes. This article introduces four common methods of circular saw blades to let everyone know about the production process of circular saw blades....

Diamond saw blade production process

2020-11-09

Diamond saw blade is a product of the combination of diamond segment and alloy blade body. This article describes the entire saw blade production process from segment production, blade body procurement, saw blade welding, inspection and testing, storage and packaging....

RETURN

RETURN