YOU ARE HERE >

HOME >

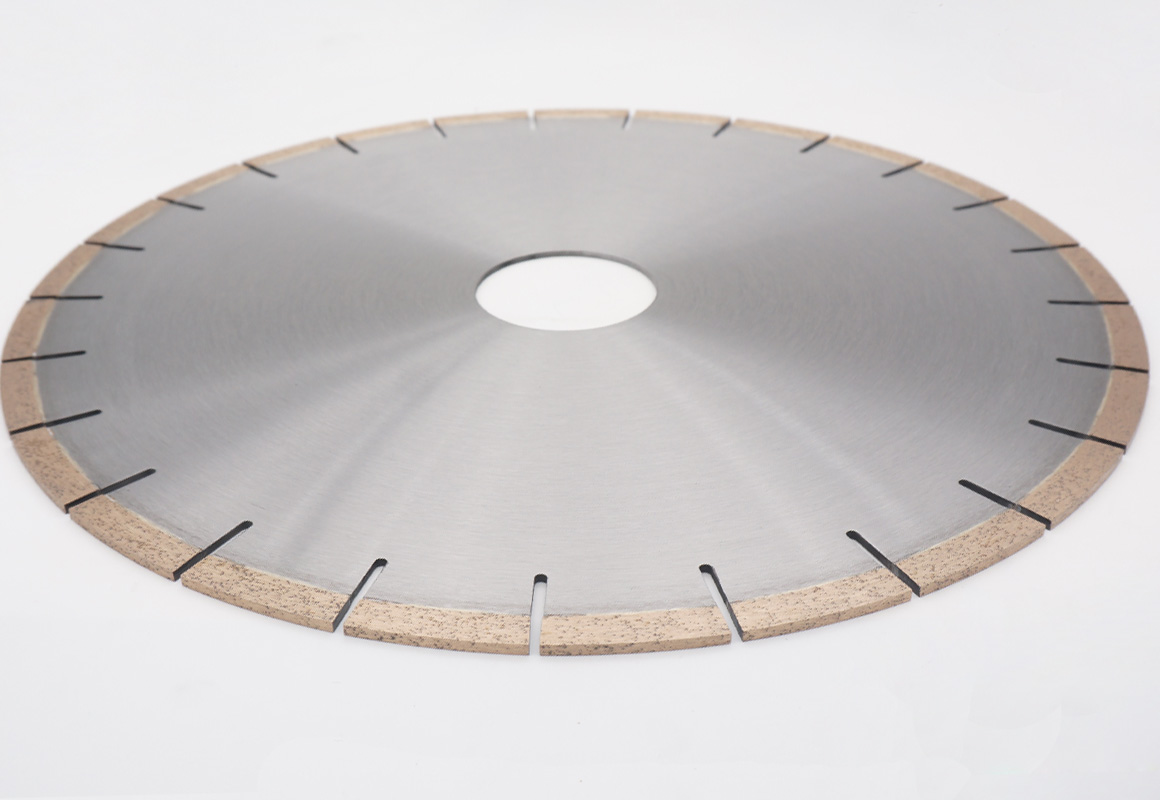

DIAMOND SAW BLADE

Maintenance and repair of diamond saw blades

Publish Date:2020-09-24

During the cutting process of diamond saw blades, the segment and the cutting surface of the stone are impacted. During the long-term impact of the saw blade, the saw blade will experience impact strain. The main manifestation of this impact strain is the change of the steel body. Softness is the most obvious manifestation. In order to reduce the impact force of the material, modern segment intentionally reduce the bond hardness. In the design of the base body, a more flexible alloy steel is used to replace the hard alloy base body. During the process, the saw blade will swing slightly, but if the cutting rate is controlled, the service life of the saw blade can be effectively increased and the stability can be ensured.In addition to the use of diamond saw blades caused by impact, heat loss is also a very big problem faced by diamond saw blades. The current method is to use running water to cool down. Under the condition of a certain sawing speed, adjust the amount of water in the cutting process, To ensure that the temperature of the diamond saw blade is kept low. In addition to cooling, increasing lubrication is also a common process for saw blade maintenance. Stone lubricants are also used. This lubricant is dissolved in water. During the cutting process, adding such lubricants can cool the saw blade, it can also provide good lubrication effect and reduce the heat in the cutting process.

Normal blade loss is the most common maintenance and repair item for diamond saw blades. Most of the current diamond saw blades use high-frequency welding to combine the blade and the steel base. After the blade is excessively worn, it can be replaced with a new segment, So that the steel base can be reused many times. The repair of the steel base is a little troublesome.

The repair of the steel base is a very tedious process, from checking the degree of wear to the final metal polishing, it goes through a lot of processes. Of course, not all diamond saw blades can be repaired, such as openings and fractures. Such saw blades cannot be repaired. The basic saw blade repair is actually the repair of the slight deformation, and blade wear. Repairing the center hole deformation and other places can generally increase the service life by 3-8 months, which greatly reduces the cost of the stone factory.

Of course, not all diamond saw blades can be repaired, because from the perspective of the nature of diamond saw blade grinding, the material of the saw blade itself is very critical. If the blade body material itself does not have the possibility of repair, then later repair it becomes empty talk. Only saw blades with good material properties, toughness and rigidity, such saw blades can be repaired.

The later maintenance and repair of diamond saw blades is a way to save costs, reduce the burden on stone processing enterprises, and increase the competitiveness of enterprises. This method is slowly recognized by people. With the development of the stone industry and sawing industry development, in the future, there will be better and more scientific saw blade maintenance methods and maintenance methods. This is also the only way for the development of diamond saw blades.

Tags:

blades

.jpg)

Installation and use process of diamond circular saw blade

2020-11-09

Diamond saw blades can be used in single blade saw, multiblade saws, infrared bridge cutting machines, hand cutter and other large and medium-sized stone machinery according to their sizes. They can also be used in angle grinders, hand cutting machines etc., the small machines are used in a wide range. This article is mainly based on the application of different saw blades in installation and cutting....

.jpg)

Diamond circular saw blade classification

2020-11-09

Diamond circular saw blades are mainly classified according to size. Generally speaking, they are divided into small-diameter saw blades, medium-diameter saw blades and large saw blades. Small saw blades are also divided according to the shape of the blade, while medium-diameter saw blades can be divided according to the cutting material or the shape of the segment, and the large saw blade is divided according to the purpose. This article introduces the classification of circular saw blades to let you better understand the relevant knowledge of diamond saw blades....

The development of diamond saw blades

2020-09-24

Among all diamond tools, diamond saw blades are the first to appear. With saw blades, cutting becomes simple. Cutting changes the entire world. In terms of decorative materials, wood is not the only choice. Stone, artificial stone, and ceramic tiles are used extensively. In terms of engineering, the cutting of asphalt, reinforced concrete and other materials has also become simpler....

Five common diamond circular saw blades

2020-12-31

Diamond circular saw blades are the largest sales volume of diamond products, accounting for more than 95% of the total sales of diamond tools. In recent years, China has conducted a lot of research on optimizing the formula of diamond circular saw blades, which has made the sawing function of diamond circular saw blades significantly improved, and the cost of blades has been greatly reduced, making domestic saw blades have strong competitiveness at home and abroad. At present, there are mainly five common circular saw blades on the market. This article gives a detailed introduction to these five different saw blades....

Common process of diamond circular saw blade

2020-09-09

Diamond circular saw blades have different manufacturing methods, and different manufacturing methods allow the saw blade to have different performances after being manufactured. And different processes can make saw blades have different sawing processes. This article introduces four common methods of circular saw blades to let everyone know about the production process of circular saw blades....

Diamond saw blade production process

2020-11-09

Diamond saw blade is a product of the combination of diamond segment and alloy blade body. This article describes the entire saw blade production process from segment production, blade body procurement, saw blade welding, inspection and testing, storage and packaging....

RETURN

RETURN