YOU ARE HERE >

HOME >

DIAMOND SAW BLADE

Diamond saw blade selection

Publish Date:2020-09-24

The price of diamond saw blades on the market now varies from high to low, and the difference in technology has led to confusion in the price of diamond saw blades. However, what is even more confusing is that even if the price of saw blades is close, their use effects will appear uneven. The situation is not only due to the difference in brands, but even if the diamond saw blades of the same manufacturer use different equipment or face different cutting objects, the results will be very different, and the difference will be very different. Why is this?In recent years, through a large amount of data and research, it has been proved that the use of equipment and processing objects is very important for the selection and process design of the diamond saw blade segment. In the process of production and use, according to the processing materials and equipment, pay attention to the following aspects in design and production:

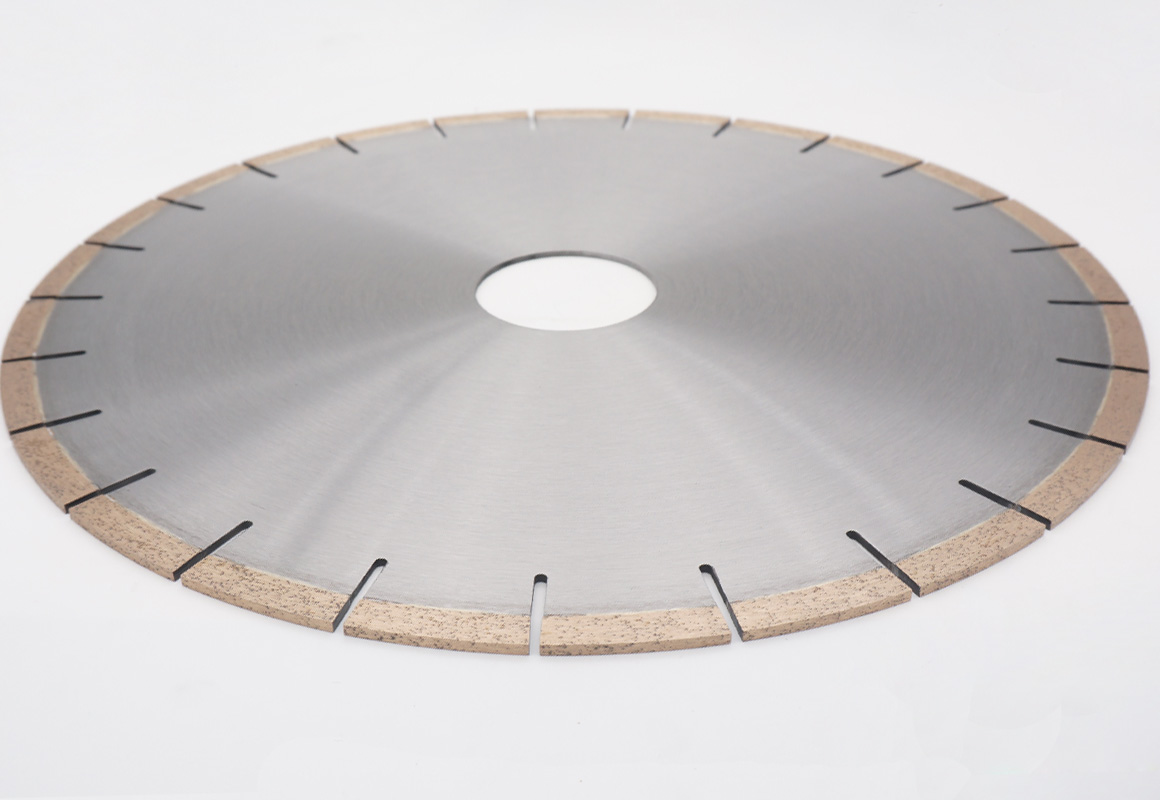

Diamond material has its own inherent advantages-indestructible, extremely hard, strong wear resistance, but its resistance to collapse is its weakness. For materials such as stone, concrete, cement, steel, artificial stone, ceramic tile, asphalt, etc., sintering can be used. However, in order to save the cost of the blade body, the secondary utilization of the blade body is very important for the saw blades for cutting stone and concrete. Therefore, a large number of stone saw blades will choose the high-frequency welding process to complete the saw. For high-strength concrete, asphalt and other materials, saw blades are mostly used for dry cutting. the recycling rate of the blade body is not high. Therefore, laser welding technology is used. Such saw blades basically do not lose teeth. However, materials such as artificial stone and ceramic tiles are too brittle, so try to choose turbo, continuous or music slot blade to cut.

For wood, the hardness is not high,so most wood saw blades will choose high-speed steel alloy. If you want to increase the life of wood saw blades, you can also choose saw blades with PCD cutters. Or TCT saw blade. These two saw blades are excellent in cutting and are suitable for cutting soft and tough materials, such as rubber, plastic, aluminum and so on.

.jpg)

For jade and glass, it is easy to break, especially jade is very precious and often very expensive, so in the process of cutting jade, saving materials and not chipping are the most basic requirements. At this time, People will choose electroplated saw blades. Because there is no welding process of the blades, the blades are very neat. With the appearance of continuous saw blades, the electroplated saw blades can handle these materials with ease. The price is relatively high (mainly because the increase in diamond concentration leads to an increase in diamond materials), but it meets the demand for ultra-thin cutting of jade, crystal and other materials.

As early as the 20th century, people discovered that during the rescue process, the saw blade was used to cut the reinforced concrete of the wall. The saw blade was slow in the cutting process, which increased the rescue time of the trapped personnel. In addition, many diamond saw blades It is required to cut in a watery environment, otherwise it will cause the thermal decline of the saw blade, resulting in the inability to cut wall panels and steel bars. Therefore, in 2010, Super Cutting designed a rescue saw blade specifically for in fire scenes, earthquakes and other rescue scenes, our saw blades can rescue the trapped people at a high cutting speed, which is 30-50% more efficient than traditional saw blades. In China, many fire brigades are equipped with speed cutting Rescue saw blade. And this kind of saw blade is a vacuum brazed saw blade.

.jpg)

These are common saw blade selection methods. In addition, it is necessary to consider the machinery that the saw blade needs to install, such as the speed, whether it supports water cutting, etc. These can help us better choose the diamond saw blade.

Tags:

blade

.jpg)

Installation and use process of diamond circular saw blade

2020-11-09

Diamond saw blades can be used in single blade saw, multiblade saws, infrared bridge cutting machines, hand cutter and other large and medium-sized stone machinery according to their sizes. They can also be used in angle grinders, hand cutting machines etc., the small machines are used in a wide range. This article is mainly based on the application of different saw blades in installation and cutting....

.jpg)

Diamond circular saw blade classification

2020-11-09

Diamond circular saw blades are mainly classified according to size. Generally speaking, they are divided into small-diameter saw blades, medium-diameter saw blades and large saw blades. Small saw blades are also divided according to the shape of the blade, while medium-diameter saw blades can be divided according to the cutting material or the shape of the segment, and the large saw blade is divided according to the purpose. This article introduces the classification of circular saw blades to let you better understand the relevant knowledge of diamond saw blades....

The development of diamond saw blades

2020-09-24

Among all diamond tools, diamond saw blades are the first to appear. With saw blades, cutting becomes simple. Cutting changes the entire world. In terms of decorative materials, wood is not the only choice. Stone, artificial stone, and ceramic tiles are used extensively. In terms of engineering, the cutting of asphalt, reinforced concrete and other materials has also become simpler....

Five common diamond circular saw blades

2020-12-31

Diamond circular saw blades are the largest sales volume of diamond products, accounting for more than 95% of the total sales of diamond tools. In recent years, China has conducted a lot of research on optimizing the formula of diamond circular saw blades, which has made the sawing function of diamond circular saw blades significantly improved, and the cost of blades has been greatly reduced, making domestic saw blades have strong competitiveness at home and abroad. At present, there are mainly five common circular saw blades on the market. This article gives a detailed introduction to these five different saw blades....

Common process of diamond circular saw blade

2020-09-09

Diamond circular saw blades have different manufacturing methods, and different manufacturing methods allow the saw blade to have different performances after being manufactured. And different processes can make saw blades have different sawing processes. This article introduces four common methods of circular saw blades to let everyone know about the production process of circular saw blades....

Diamond saw blade production process

2020-11-09

Diamond saw blade is a product of the combination of diamond segment and alloy blade body. This article describes the entire saw blade production process from segment production, blade body procurement, saw blade welding, inspection and testing, storage and packaging....

RETURN

RETURN