Properties of graphite mould for sintered diamond segment

Graphite has good conductivity, and its thermal conductivity is also better than the general non-metallic materials and some metal materials. The compressive strength of dense graphite can reach 45MPa, so graphite is often used as heat forming materials. Graphite is selected as the hot pressing die material for hot pressing diamond nodal block, which is based on these characteristics of graphite.

Graphite has a small coefficient of thermal expansion, which can withstand the rapid change of temperature without cracking; nodal matrix materials are mostly metallic materials, whose coefficient of thermal expansion is much larger than graphite, which brings convenience for de-moulding; in addition, when graphite is hot pressed, the surface reacts with oxygen to generate Co or CO2 gas, which can protect diamond and matrix materials from oxidation; graphite has low hardness and is easy to be used In machining.

Graphite, as a mold material, also has some shortcomings, mainly because its porosity is very large compared with metal material. Therefore, during the course of hot pressing, the liquid metal (low melting point component of melting) may be squeezed into the void, making the mold brittle and easy to crack, or the mold wall roughening and deformation during mold unloading, which will affect the use times.

In order to meet the requirements of hot pressing process conditions, when selecting the graphite brand of hot pressing die, the following requirements shall be met as far as possible:

(1) Compressive strength ≥ 35 ~ 45MPa;

(2) Generally, the density is more than 1.6g/cm3, and the porosity is less than 30%.

The control ratio of the metal content in the diamond segment bond

Selection of diamond powder for diamond segment

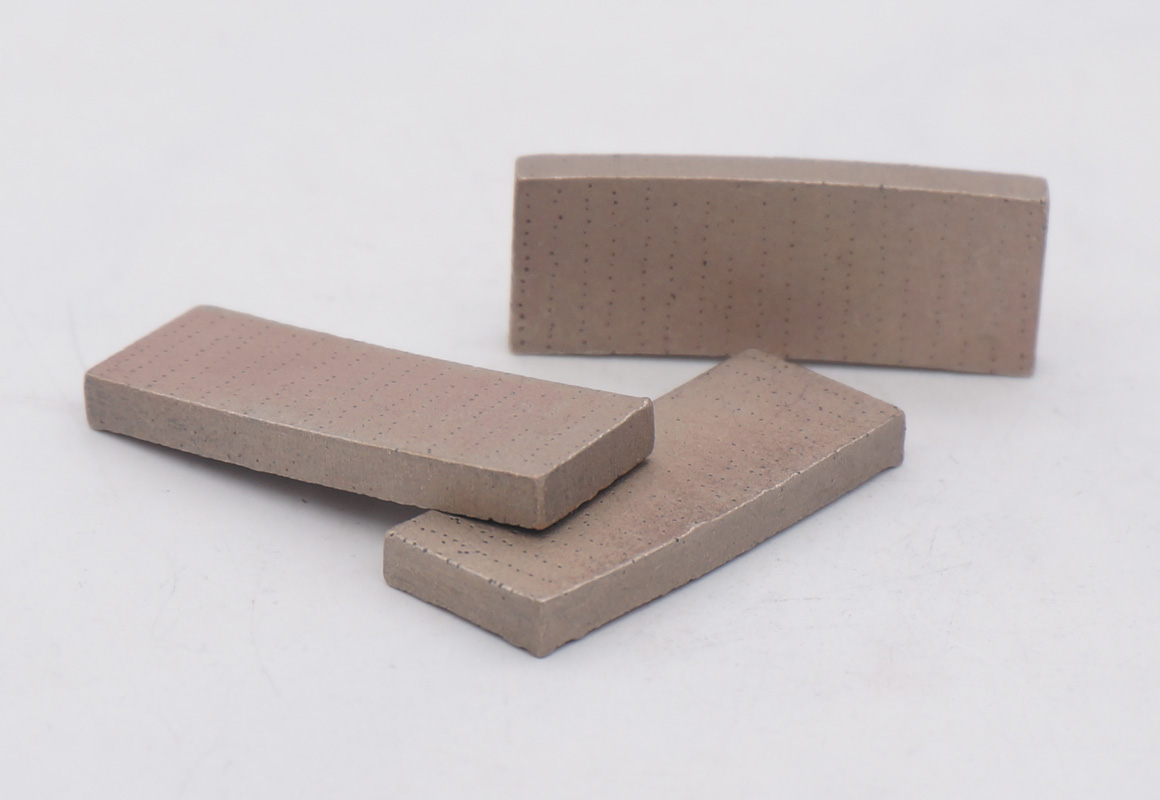

Arrayed diamond segment and the saw blade

Commonly used bond for diamond segment

Common problems and treatment methods of diamond segment

RETURN

RETURN