YOU ARE HERE >

HOME >

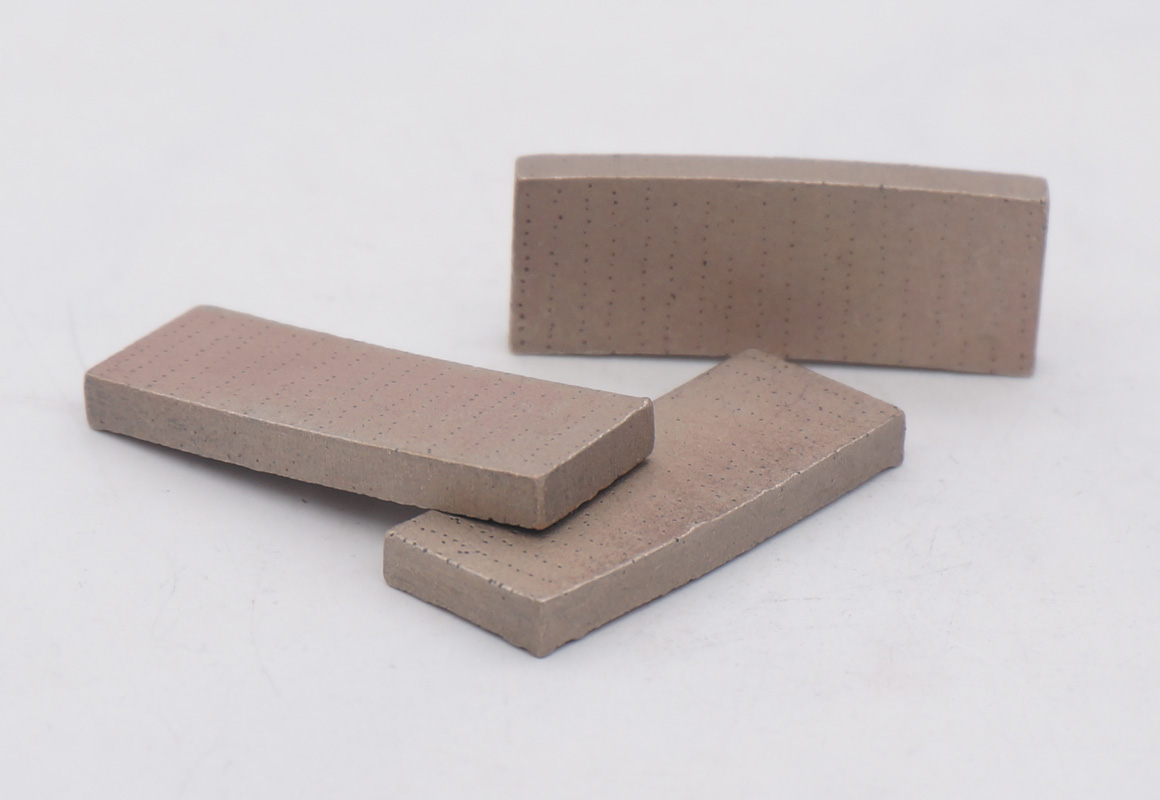

DIAMOND SEGMENT

Formula design of diamond segment

Publish Date:2020-10-16

The performance of the diamond segment mainly depends on the structural parameters of the formula design. The structural parameters of the formula include the grade, the particle size and the concentration of the diamond powder and the ratio of the matrix material components. The ratio of the matrix components determines the strength and hardness, density and wear resistance and toughness. When designing the formula, it should be based on the nature of the processed object, such as the hardness, strength, particle thickness, abrasiveness, the technical parameters of the processing method (such as cutting rate, feed speed, linear speed), processing quality, cutting efficiency and service life to comprehensively consider, and design rationally.

Consider formula design based on the nature of the processing object: rock hardness, high strength, fine particles, strong abrasiveness, it requires to use diamonds with high grade and fine particle size, and matrix bond with higher hardness and strength. If the rock is softer, coarser particles, and weak abrasiveness, it can be used for diamond with lower grade and coarser particle size and matrix with lower hardness and strength.

Consider the formula based on the technical parameters of the processing method: When at high linear speed and fast cutting rate, diamond and the matrix are mainly impact wear, in this case, need to use the diamond with high grade, high strength and fine particle size and the matrix with high strength and good toughness are required. When the linear speed and cutting rate are low, diamond and the matrix are mainly worn by grinding, diamond with lower strength and coarser particle size and the matrix with better wear resistance can be used. Usually the rotation speed of the equipment is fixed, the linear speed of the saw blade is unchanged, and the speed of the cutting speed is controlled by the operator. When high grade and fine particle size diamond in the segment, and high strength and hardness of the matrix, it can allow the cutting rate to increase. The cutting rate is equal to the cutting speed by cutting depth. When the cutting rate is the same, fast cutting speed with small cutting depth is beneficial to the diamond segment.

Consider the formula according to the processing quality requirements: high cutting efficiency, use of high-grade and coarse grit diamonds. To have a long service life, prepare fine grit diamonds, higher diamond concentration and matrix with good wear resistance, strength and toughness.

In summary, the following elements need to be considered during the processing of diamond segments:

The hardness, strength, particle size, abrasiveness, processing method, machinery used, processing efficiency (speed and efficiency) and service life of the processing object are the basic parts of the formula design. With these parameters to have the benchmark policy for adjusting segment. According to these different parameters, it uses different diamond particle size, concentration and strength, different matrix binders and other materials, and then according to the matrix binder material to control the sintering temperature and pressure, and finally form a personalized and unique diamond segment product.

Tags:

The control ratio of the metal content in the diamond segment bond

2020-08-17

The diamond segment is composed of two parts of the bond and the diamond, and the bond is actually not just one component, it is made of paraffin, nickel, tin, zinc, copper, iron, silicon carbide, tungsten and other metal powders, and non-metallic powder, in which copper, iron, silicon carbide and tungsten are the main components, while nickel, tin, and zinc are the metal binders, which make the diamond and the bond more firmly....

Selection of diamond powder for diamond segment

2020-09-24

During the diamond segment working process, the role of diamond powder crystals is very important, especially in the cutting process, a good crystal can be very good in anti-breakage ability, reduce the power consumption of the equipment, and extend the life of the cutting....

Arrayed diamond segment and the saw blade

2020-12-29

In traditional diamond segment products, the diamond powder in the segment is arranged in disorder. During the cutting process, the exposed diamond will impact the stone surface at various angles, and the exposed height of the diamond will vary. As a result, the diamond is not evenly stressed, and diamonds with high exposure are prone to fracture. In order to improve this situation and make the diamond distribution more uniform, arrayed segments have emerged. Weld the arrayed segment on the blade steel body to be an arrayed saw blade....

Commonly used bond for diamond segment

2020-09-09

There are four commonly used bonds for diamond segment. These four bonds are matched with different diamond powders according to different materials to make diamond segments for different purposes. Each bond has its advantages and disadvantages. In the process of designing the diamond segment, we must take advantage and reinforce its shortcomings. This is the charm of diamond segment production and design....

Common problems and treatment methods of diamond segment

2020-08-17

Diamond segment is a non-standard industry in modern industry. The instability of product quality is the most common problem. The following are some of the most prone problems and related solutions in producing diamond segments. Through these instructions, Let everyone better understand the details of diamond segments production process....

Formula design of diamond segment

2020-10-16

Diamond segment is a very special segmented product. Through different formulas and different processes, products with different appearances, different cutting performances and different cutting life can be produced. The most attractive part of this product is that it is not Certainty, especially the new formula, needs to consider factors such as the object to be processed, the matrix metal bond, diamond grade and particle size, pressure and sintering temperature....

RETURN

RETURN