YOU ARE HERE >

HOME >

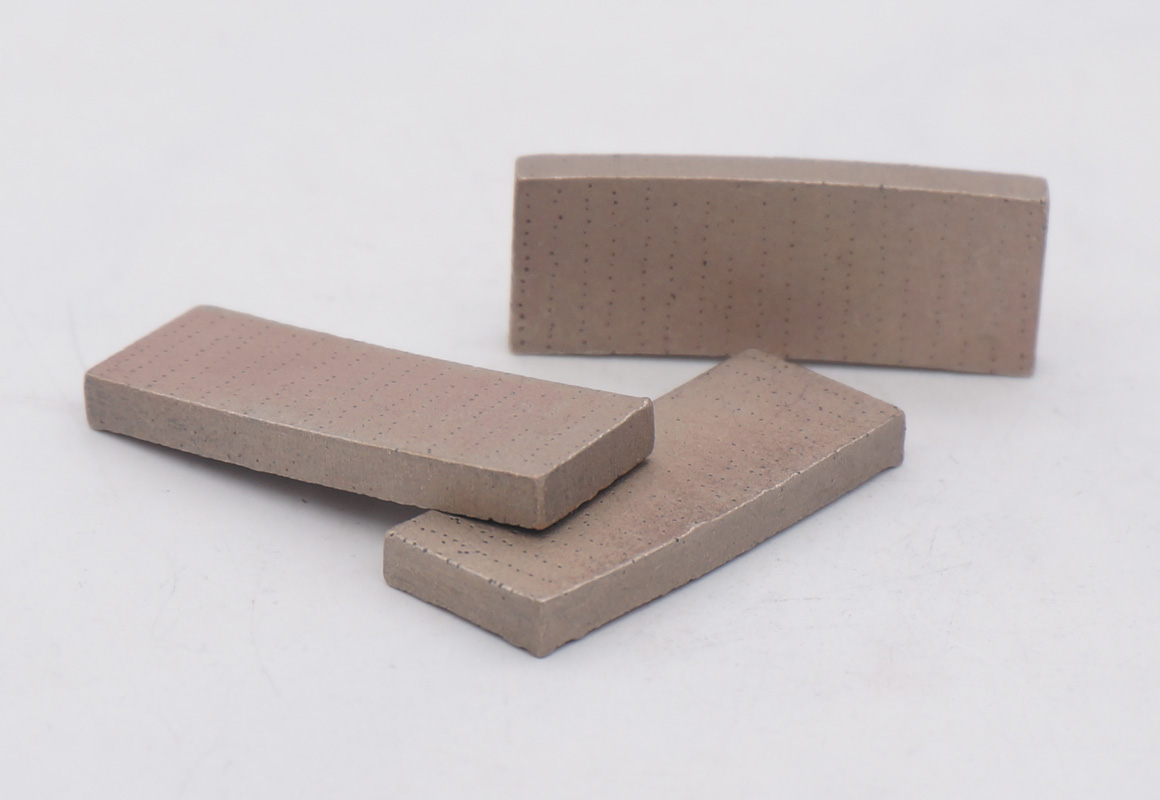

DIAMOND SEGMENT

The control ratio of the metal content in the diamond segment bond

Publish Date:2020-08-17

So since these bonding agents can make the material bond stronger, do they need a lot of use? This is not the case. The bonding agent has a bonding effect, and a large amount of the bonding agent will cause the tool tip to flow. What if there is too little binder? Then there will be insufficient adhesion, insufficient wear resistance of the segment, and some metal powder in the carcass can play a role in fixing the diamond, which greatly improves the life of the segment. Below we talk about the role and dosage of the three commonly used metal binding agents.Nickel is a kind of metal powder commonly used in diamond segments. Nickel and iron elements are very good combination. They can form a stable and rust-proof metal material tightly, and nickel has good holding power and certain wear resistance to diamond In addition, the nickel material has both polishing properties, so it is often used in iron-based granite segments. However, the price of nickel powder is relatively expensive, so it should not be used in large quantities. Generally, it is controlled between 5% and 6%. The nickel content of the granite blade with better wear resistance can be adjusted to 8-9%, usually more than 10%, because the ingredients exceeding 10% will cause uneven sintering of the segment, and the quality problem of the deviation of the segment size. Of course, the combination of copper base and nickel commonly used in marble segments can also make the segment not easy to rust, so almost all manufacturers will add this metal element to the segment.

Tin and zinc are low-melting metals. The sintering temperature of the segment is generally around 800 degrees. At 730 degrees Celsius, tin and zinc are completely melted during the sintering process of the segment. The molten metal passes through the gap between the powder of the segment. Cast iron, nickel, copper, diamond, etc. play a bonding role. Generally speaking, the tin content in the segment will be too much. Zinc will start to oxidize at 225 degrees. During the cutting process, the oxidized zinc has a negative effect on the segment, so the tin content is controlled at about 8% Or the total content of tin + zinc is about 8%.

The metal bond must be consistent with the diamond wear rate. The advantage of this is that the diamond particles are continuously exposed to the working surface of the segment, so that the sharpness and processing efficiency of the saw blade can be better maintained. The strength of the bond is higher than that of diamond wear, so the segment has no cutting edge, and the segment will not be able to cut directly. Conversely, if the wear resistance of the bond is very low, then the diamond wear speed cannot keep up with the shedding speed, and it will become intolerant to cutting. Therefore, the amount of metal elements in the binder still depends on the actual cutting situation.

Tags:

The control ratio of the metal content in the diamond segment bond

2020-08-17

The diamond segment is composed of two parts of the bond and the diamond, and the bond is actually not just one component, it is made of paraffin, nickel, tin, zinc, copper, iron, silicon carbide, tungsten and other metal powders, and non-metallic powder, in which copper, iron, silicon carbide and tungsten are the main components, while nickel, tin, and zinc are the metal binders, which make the diamond and the bond more firmly....

Selection of diamond powder for diamond segment

2020-09-24

During the diamond segment working process, the role of diamond powder crystals is very important, especially in the cutting process, a good crystal can be very good in anti-breakage ability, reduce the power consumption of the equipment, and extend the life of the cutting....

Arrayed diamond segment and the saw blade

2020-12-29

In traditional diamond segment products, the diamond powder in the segment is arranged in disorder. During the cutting process, the exposed diamond will impact the stone surface at various angles, and the exposed height of the diamond will vary. As a result, the diamond is not evenly stressed, and diamonds with high exposure are prone to fracture. In order to improve this situation and make the diamond distribution more uniform, arrayed segments have emerged. Weld the arrayed segment on the blade steel body to be an arrayed saw blade....

Commonly used bond for diamond segment

2020-09-09

There are four commonly used bonds for diamond segment. These four bonds are matched with different diamond powders according to different materials to make diamond segments for different purposes. Each bond has its advantages and disadvantages. In the process of designing the diamond segment, we must take advantage and reinforce its shortcomings. This is the charm of diamond segment production and design....

Common problems and treatment methods of diamond segment

2020-08-17

Diamond segment is a non-standard industry in modern industry. The instability of product quality is the most common problem. The following are some of the most prone problems and related solutions in producing diamond segments. Through these instructions, Let everyone better understand the details of diamond segments production process....

Formula design of diamond segment

2020-10-16

Diamond segment is a very special segmented product. Through different formulas and different processes, products with different appearances, different cutting performances and different cutting life can be produced. The most attractive part of this product is that it is not Certainty, especially the new formula, needs to consider factors such as the object to be processed, the matrix metal bond, diamond grade and particle size, pressure and sintering temperature....

RETURN

RETURN