YOU ARE HERE >

HOME >

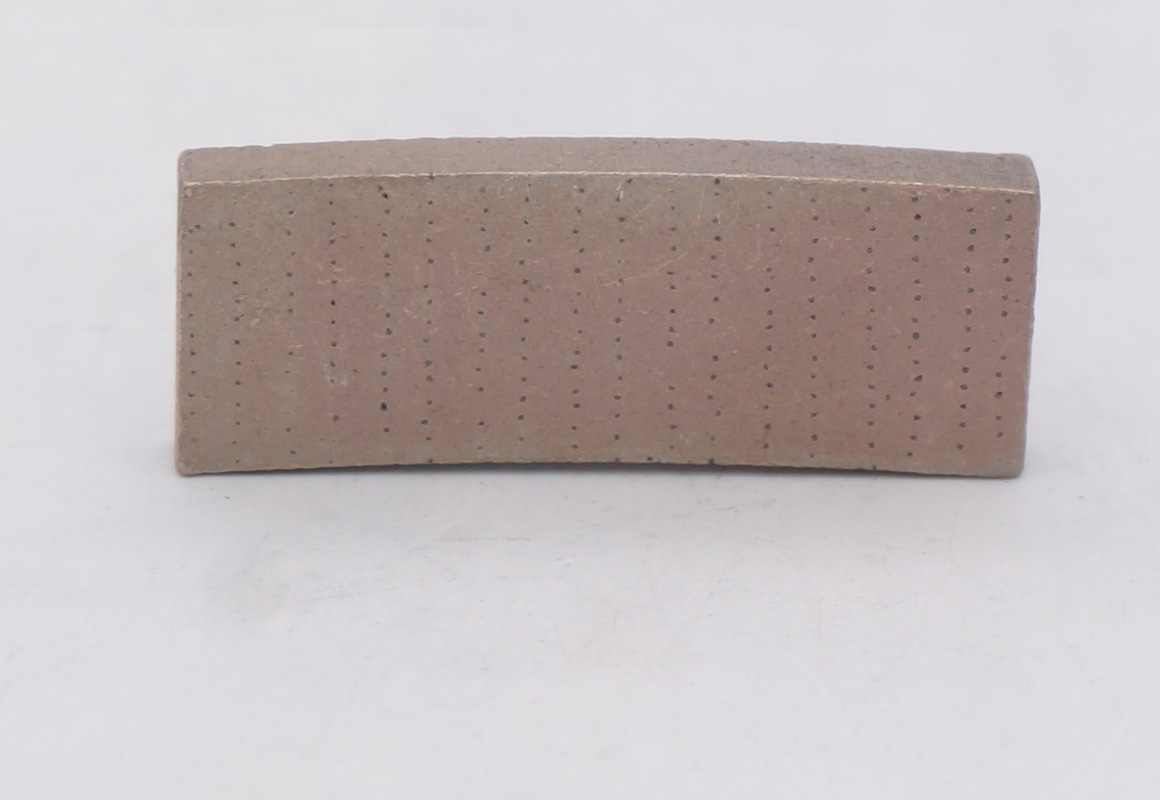

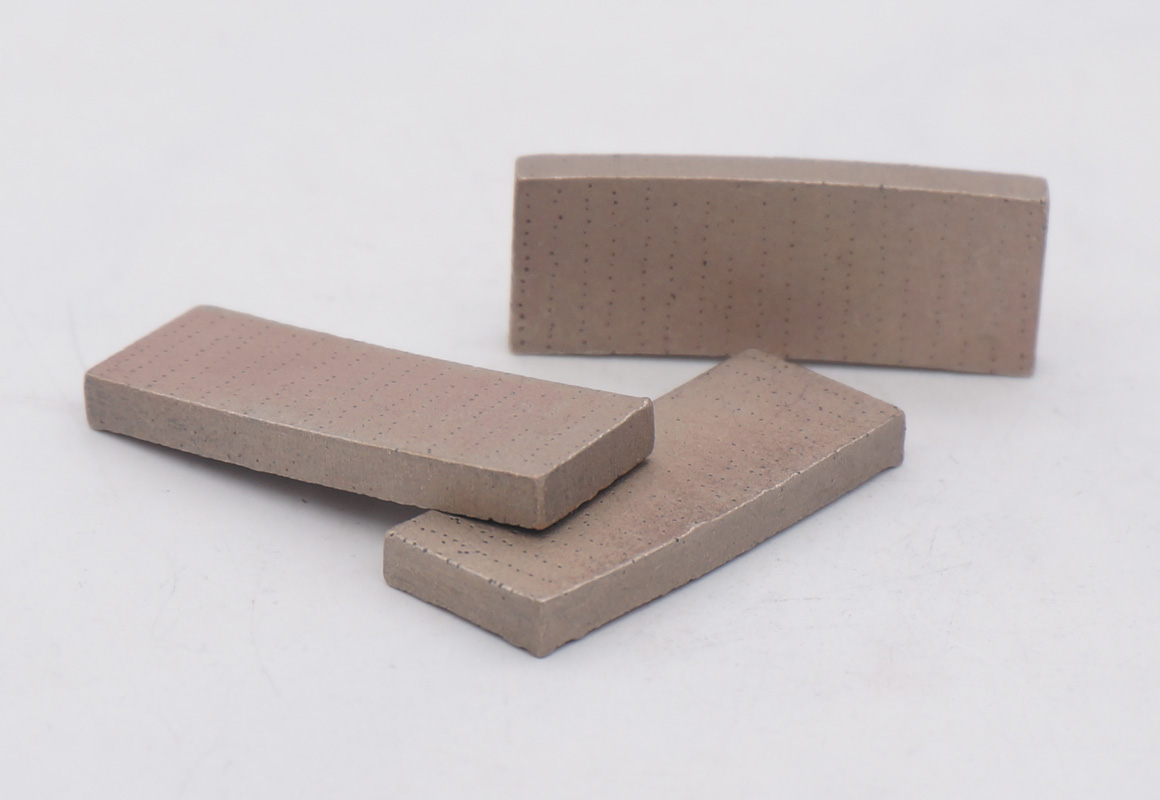

DIAMOND SEGMENT

Arrayed diamond segment and the saw blade

Publish Date:2020-12-29

Diamond segments can be classified according to different sizes and uses. In fact, there is another classification method, which is based on the fixed order of diamond arrangement and disordered arrangement. Facts have proved that the life and efficiency of arrayed segments are 30-40% more disordered segment, therefore, the future development trend of segment should be towards sharper and more efficient trends. Here, by introducing the production process and technology of arrayed diamond segments, let you better understand the arrayed diamond segments and saw blades.

1. The diamond cannot be naturally oriented and arranged in an orderly manner in the pre-alloyed powder, so the matrix powder must be cold pressed into a sheet-like thin blank, and then the diamonds are arranged on the thin blank in an orderly orientation. The number of layers of the thin blank in a segment is calculated according to the number of diamond layers designed (the number of layers of the thin blank = the number of diamond layers -1). The amount of powder used for each thin blank layer = total weight of the segment / number of thin blank layers.

2. Follow the diamond arrangement method designed by calculation and simulation, and use a small and medium power laser to make a regular six-sided hole in the copper template. The thickness of the selected copper plate is slightly larger than the average diameter of the diamond, about 0.5mm, and the size of the hole should be greater than 1 time the average diameter of the diamond and less than 2 times the average diameter to ensure that each hole can be separated One diamond but cannot hold two diamonds. In addition, the diamond single crystals that fall into the hole are aligned forward with a ratio of 75%, thereby realizing the directional distribution of the diamond single crystals.

3. Spray a thin layer of special pressure-sensitive adhesive on the thin matrix blank, then cover the punched red copper plate on the thin matrix blank, sprinkle the diamonds on the copper plate, and then sweep the diamonds into the holes to ensure that each hole a diamond in. Uncovering the copper plate, the diamonds form an orderly arrangement on the matrix.

4. Combine the multi-layer thin blanks with oriented and ordered diamonds together, and use a cold press to make the segment shape. In order to eliminate the sprayed pressure-sensitive adhesive, put the cold-pressed segment into the vacuum sintering furnace, place it at 400 degrees centigrade for about half an hour to fully volatilize the pressure-sensitive adhesive.

5. When sintering, vertical loading molds shall be used to stagger horizontally to ensure that the diamond particles are still arranged in an orderly manner after sintering..

6. Finally, dismantle the mold, grind the arc, weld, sharpen and trim.

The production process for arrayed segment diamond saw blades in each unit takes an average of more than 30 minutes longer than the production of ordinary diamond saw blades, plus the investment in supporting equipment, the addition of auxiliary facilities, and the demand for high-tech workers, resulting the development and production costs of arrayed diamond saw blades remain high, and the market benefit is still unclear, which is difficult to be generally accepted by the current Chinese stone tool industry. However, in the future, due to the increase in the cost of diamonds, there will be a place for the energy-saving, material-saving, and processing efficiency of orderly segments.

Tags:

The control ratio of the metal content in the diamond segment bond

2020-08-17

The diamond segment is composed of two parts of the bond and the diamond, and the bond is actually not just one component, it is made of paraffin, nickel, tin, zinc, copper, iron, silicon carbide, tungsten and other metal powders, and non-metallic powder, in which copper, iron, silicon carbide and tungsten are the main components, while nickel, tin, and zinc are the metal binders, which make the diamond and the bond more firmly....

Selection of diamond powder for diamond segment

2020-09-24

During the diamond segment working process, the role of diamond powder crystals is very important, especially in the cutting process, a good crystal can be very good in anti-breakage ability, reduce the power consumption of the equipment, and extend the life of the cutting....

Arrayed diamond segment and the saw blade

2020-12-29

In traditional diamond segment products, the diamond powder in the segment is arranged in disorder. During the cutting process, the exposed diamond will impact the stone surface at various angles, and the exposed height of the diamond will vary. As a result, the diamond is not evenly stressed, and diamonds with high exposure are prone to fracture. In order to improve this situation and make the diamond distribution more uniform, arrayed segments have emerged. Weld the arrayed segment on the blade steel body to be an arrayed saw blade....

Commonly used bond for diamond segment

2020-09-09

There are four commonly used bonds for diamond segment. These four bonds are matched with different diamond powders according to different materials to make diamond segments for different purposes. Each bond has its advantages and disadvantages. In the process of designing the diamond segment, we must take advantage and reinforce its shortcomings. This is the charm of diamond segment production and design....

Common problems and treatment methods of diamond segment

2020-08-17

Diamond segment is a non-standard industry in modern industry. The instability of product quality is the most common problem. The following are some of the most prone problems and related solutions in producing diamond segments. Through these instructions, Let everyone better understand the details of diamond segments production process....

Formula design of diamond segment

2020-10-16

Diamond segment is a very special segmented product. Through different formulas and different processes, products with different appearances, different cutting performances and different cutting life can be produced. The most attractive part of this product is that it is not Certainty, especially the new formula, needs to consider factors such as the object to be processed, the matrix metal bond, diamond grade and particle size, pressure and sintering temperature....

RETURN

RETURN