YOU ARE HERE >

HOME >

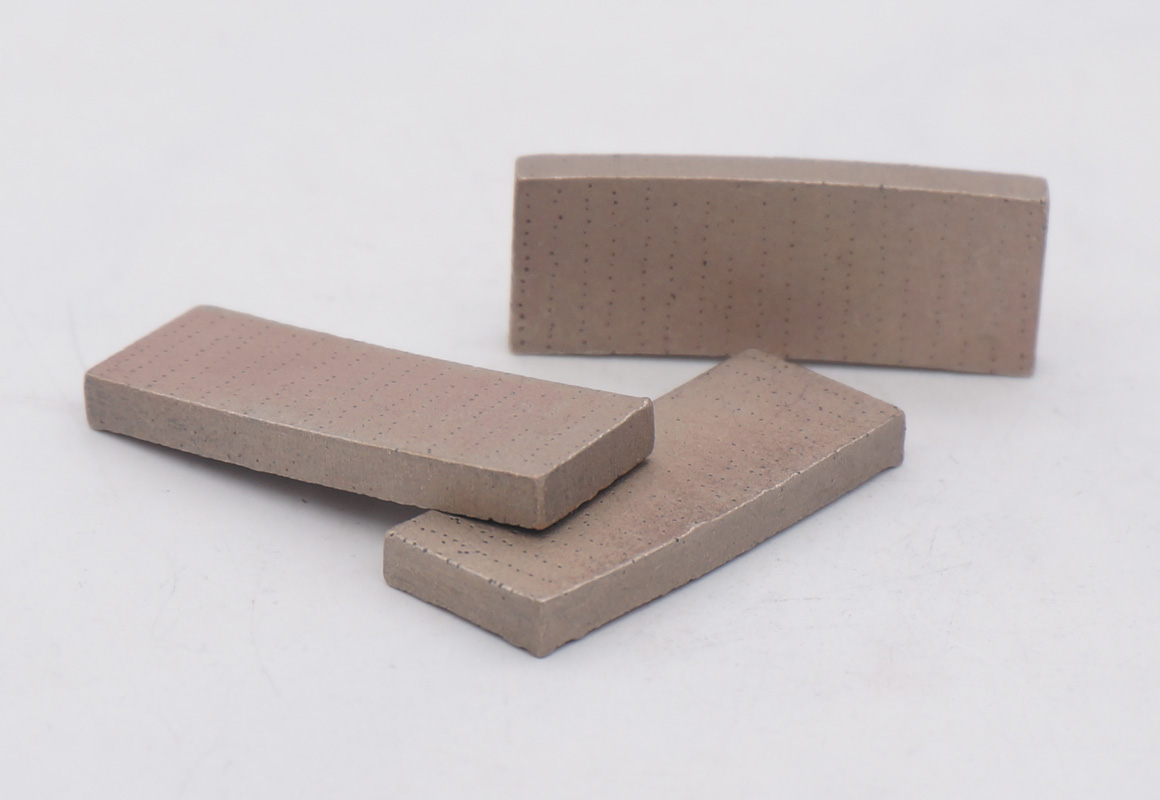

DIAMOND SEGMENT

The importance of the transition of the diamond saw blade and the detection of the segment unloading the die

Publish Date:2020-03-11

The diamond saw blade is composed of a base and a segment. The nodal block consists of impregnated diamond layer and transition layer, as shown in the figure below. The transition layer is a pure matrix layer, which does not contain diamond. It is used to connect the diamond impregnated layer and braze the diamond impregnated layer on the substrate through the transition layer. Therefore, good welding performance is also required. The poor performance of the transition house will cause the segment to fall off from the base under the action of high alternating stress, thus affecting the safety of the saw blade.Generally, the transition layer materials can not contain low melting point metals, such as Sn, Zn and other elements, because these elements are easy to evaporate and vaporize at high temperature and produce pores. Co, Ni and some alloy materials are usually used in the formulation of transition layer. Although WC can increase the wear resistance of the weld and the transition layer, high content of WC will lead to defects such as cavities and slag inclusions, and even brittle fracture. In order to solve this contradiction, adding a small amount of Mn and Cr in the transition layer material can not only produce solution strengthening, increase wear resistance, but also reduce porosity. In addition, if the components of the cutting layer and the transition layer are too different, they are easy to fracture at the junction of the two layers due to the uneven thermal stress.

Quality inspection must be done after the head is sintered to check the quality of sintering. The quality inspection of the diamond segment produced by the hot pressing method includes:

1. Observe whether the shape is combined to make single requirements, that is, the graphite mold is not wrong, and each segment is required to observe;

2. Use vernier caliper to measure whether its length, thickness and height meet the requirements. The general causes of oversize include: the pressure is too small or the temperature is too low, the pressure position is not flattened; the pressure head is installed wrongly, the height of the upper pressure head is too small; the pressure head strength is low or the installation is skewed, and the pressure head is broken during the pressurization process. The reason for the small size of the segment is similar to it, generally because the upper head is too high or the upper and lower heads are installed; if the size of the segment is too large or too small, it will be burned, processed or scrapped according to the actual situation; the same type of segment can also be welded on the same pair of saw blades.

3. Calculate the loss of sintering and the density of the segment by weighing with a pharmaceutical balance. Generally, the weight consumption is not more than 7-8%.

4. The hardness value of the cutting head with the hardness tester is usually Rockwell hardness tester, which can measure the HRB and HRC values. Different saw blades have different requirements for the hardness of the segment. For example, the hardness of marble saw blade head is required to be over hrb65, granite saw blade head is required to be over hrb75, and concrete saw blade is required to be over hrb90.

Tags:

blade

The control ratio of the metal content in the diamond segment bond

2020-08-17

The diamond segment is composed of two parts of the bond and the diamond, and the bond is actually not just one component, it is made of paraffin, nickel, tin, zinc, copper, iron, silicon carbide, tungsten and other metal powders, and non-metallic powder, in which copper, iron, silicon carbide and tungsten are the main components, while nickel, tin, and zinc are the metal binders, which make the diamond and the bond more firmly....

Selection of diamond powder for diamond segment

2020-09-24

During the diamond segment working process, the role of diamond powder crystals is very important, especially in the cutting process, a good crystal can be very good in anti-breakage ability, reduce the power consumption of the equipment, and extend the life of the cutting....

Arrayed diamond segment and the saw blade

2020-12-29

In traditional diamond segment products, the diamond powder in the segment is arranged in disorder. During the cutting process, the exposed diamond will impact the stone surface at various angles, and the exposed height of the diamond will vary. As a result, the diamond is not evenly stressed, and diamonds with high exposure are prone to fracture. In order to improve this situation and make the diamond distribution more uniform, arrayed segments have emerged. Weld the arrayed segment on the blade steel body to be an arrayed saw blade....

Commonly used bond for diamond segment

2020-09-09

There are four commonly used bonds for diamond segment. These four bonds are matched with different diamond powders according to different materials to make diamond segments for different purposes. Each bond has its advantages and disadvantages. In the process of designing the diamond segment, we must take advantage and reinforce its shortcomings. This is the charm of diamond segment production and design....

Common problems and treatment methods of diamond segment

2020-08-17

Diamond segment is a non-standard industry in modern industry. The instability of product quality is the most common problem. The following are some of the most prone problems and related solutions in producing diamond segments. Through these instructions, Let everyone better understand the details of diamond segments production process....

Formula design of diamond segment

2020-10-16

Diamond segment is a very special segmented product. Through different formulas and different processes, products with different appearances, different cutting performances and different cutting life can be produced. The most attractive part of this product is that it is not Certainty, especially the new formula, needs to consider factors such as the object to be processed, the matrix metal bond, diamond grade and particle size, pressure and sintering temperature....

RETURN

RETURN