YOU ARE HERE >

HOME >

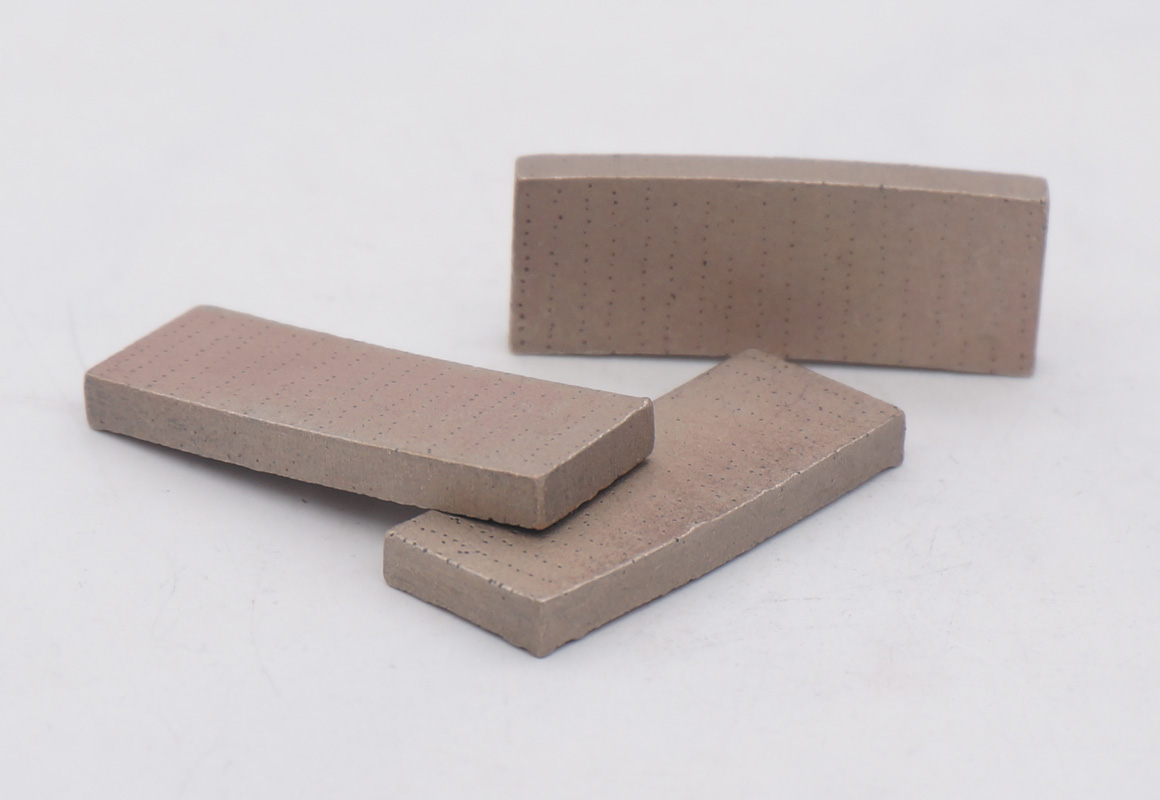

DIAMOND SEGMENT

How to extend the cutting life of diamond segment

Publish Date:2020-12-31

The diamond segment is a diamond agglomerated product welded to the saw blade body. During the diamond segment production process, through high temperature and high pressure, the diamond and the matrix powder are firmly combined physically and chemically to form a stronger structure. However, in the process of cutting stone, both the diamond powder and the matrix will be consumed. Under normal circumstances, the consumption of diamond is synchronized with the matrix, and the diamond segment can reach the best service life. This article introduces how to reduce the consumption of diamond and how to reduce the consumption of matrix, hoping to help you extend the cutting life of the diamond segment.

Diamond is the hardest material in nature discovered by humans so far. In the cutting process, the wear of stone powder to diamond is extremely small. There are three main reasons for the wear of diamond. First, the strong collision between diamond and stone. The force causes the diamond to break and shatter; second, the diamond generates high heat during the cutting process, and this heat cannot be dissipated, resulting in high-temperature carbonization of the diamond, causing the diamond to become brittle and causing consumption; third, the use of poor grade diamonds, In the process of cutting the stone, it is constantly smoothed. In order to avoid these problems, it is very important to choose diamond that matches the hardness of the stone during the cutting process. Then, the amount of cooling water and the use of coolant during the cutting process are also effective methods to help improve the service life of the diamond segment.

Of course, the main problem with the diamond segment life is the matrix. The main reason for most of the diamond segment are not durable is that the material of the matrix is too soft or not wear-resistant in the process of cutting the stone The diamond powder will fall off in large quantities, which is the main reason for the insufficient diamond segment life.

The matrix, also known as diamond bond, is mainly composed of metal powders, such as copper, iron, cobalt, silicon carbide, tin and other metals. Since it is composed of different metal powders, the matrix will appear if the content of various metals is inconsistent. The hardness is different, but no matter which kind of matrix, its hardness is lower than diamond, so in the process of processing stone, especially granite stone, the use of circulating water will cause the stone powder or particles to affect the matrix twice. Wear, this kind of wear is very fatal, and it is also the most important factor affecting the life of the diamond segment.

In order to reduce the wear of stone powder and stone particles on the diamond segment, we can adopt several methods. When the stone powder is purified, you can choose: natural sinking method, mechanical removal method, chemical flocculation method. The natural sinking method is more suitable for removing stone powder with relatively large particles, but it takes time to filter. The best method at present is to filter the water inlet with a mesh screen. The mechanical removal method and chemical flocculation method are suitable for removing small and medium stone particles powder are widely used. In addition to these, in the cutting process, increasing the water intake, the design of the diamond segment with a multi-layer non-working layer structure, the design of the upper width and the lower narrow, etc. can improve the chip removal and increase diamond segment life.

Tags:

The control ratio of the metal content in the diamond segment bond

2020-08-17

The diamond segment is composed of two parts of the bond and the diamond, and the bond is actually not just one component, it is made of paraffin, nickel, tin, zinc, copper, iron, silicon carbide, tungsten and other metal powders, and non-metallic powder, in which copper, iron, silicon carbide and tungsten are the main components, while nickel, tin, and zinc are the metal binders, which make the diamond and the bond more firmly....

Selection of diamond powder for diamond segment

2020-09-24

During the diamond segment working process, the role of diamond powder crystals is very important, especially in the cutting process, a good crystal can be very good in anti-breakage ability, reduce the power consumption of the equipment, and extend the life of the cutting....

Arrayed diamond segment and the saw blade

2020-12-29

In traditional diamond segment products, the diamond powder in the segment is arranged in disorder. During the cutting process, the exposed diamond will impact the stone surface at various angles, and the exposed height of the diamond will vary. As a result, the diamond is not evenly stressed, and diamonds with high exposure are prone to fracture. In order to improve this situation and make the diamond distribution more uniform, arrayed segments have emerged. Weld the arrayed segment on the blade steel body to be an arrayed saw blade....

Commonly used bond for diamond segment

2020-09-09

There are four commonly used bonds for diamond segment. These four bonds are matched with different diamond powders according to different materials to make diamond segments for different purposes. Each bond has its advantages and disadvantages. In the process of designing the diamond segment, we must take advantage and reinforce its shortcomings. This is the charm of diamond segment production and design....

Common problems and treatment methods of diamond segment

2020-08-17

Diamond segment is a non-standard industry in modern industry. The instability of product quality is the most common problem. The following are some of the most prone problems and related solutions in producing diamond segments. Through these instructions, Let everyone better understand the details of diamond segments production process....

Formula design of diamond segment

2020-10-16

Diamond segment is a very special segmented product. Through different formulas and different processes, products with different appearances, different cutting performances and different cutting life can be produced. The most attractive part of this product is that it is not Certainty, especially the new formula, needs to consider factors such as the object to be processed, the matrix metal bond, diamond grade and particle size, pressure and sintering temperature....

RETURN

RETURN