The reason and sintering technology of the solid phase sintering of diamond segment

Most of the metal matrix of diamond segment contains components with low melting point, such as Sn, Zn, etc., so theoretically, the sintering of diamond nodule belongs to multi-component liquid phase sintering. However, whether the liquid phase sintering can be carried out smoothly depends on three basic conditions related to the properties of the liquid phase, i.e. the better wettability of the liquid phase relative to the surface of the solid phase particles; the certain solubility of the solid phase in the liquid phase; and the appropriate amount of the liquid phase, taking the gap that can fill the solid phase particles as the limit. Because the content of low melting point components in the binder used at present is generally less than 10%, so the sintering of diamond nodule is mainly solid-phase sintering.

The sintering process of diamond bit mainly includes the control of sintering temperature, pressure and time. At present, the typical sintering process curve of double step platform is mostly used, as shown in the figure above. In order to improve the formability of diamond nodal powder, a small amount of liquid paraffin was added. In addition to dewaxing, the first sintering platform with low temperature and pressure in the process curve also needs a small amount of low melting point metal powder in the compact to form a liquid phase, which is then filled into the gap of skeleton phase powder by capillary action. If the temperature and pressure rise too fast, it is easy to produce "flow material" in the sintering process, thus affecting the densification of the nodule. It is generally believed that the sintering temperature has the greatest influence on the hardness and strength of the nodule in the sintering process, followed by the sintering time, while the pressure over a certain value has no significant influence on the nodule performance.

The control ratio of the metal content in the diamond segment bond

Selection of diamond powder for diamond segment

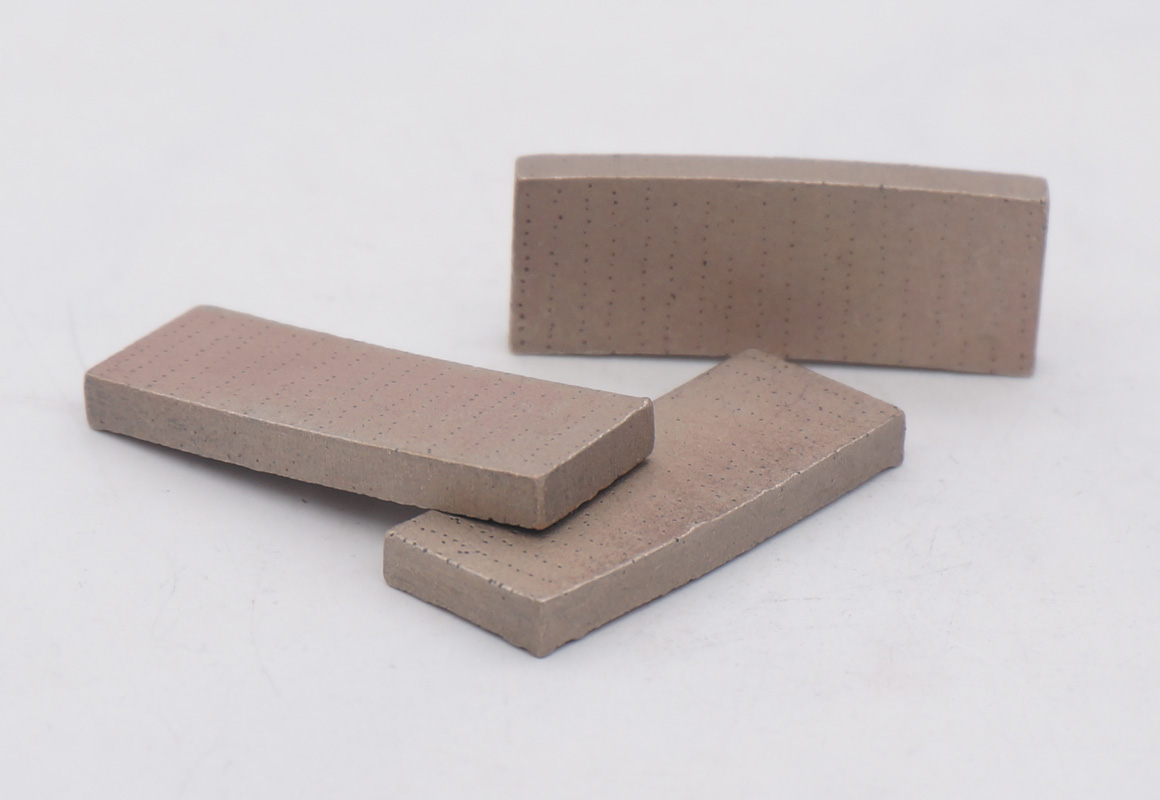

Arrayed diamond segment and the saw blade

Commonly used bond for diamond segment

Common problems and treatment methods of diamond segment

RETURN

RETURN