YOU ARE HERE >

HOME >

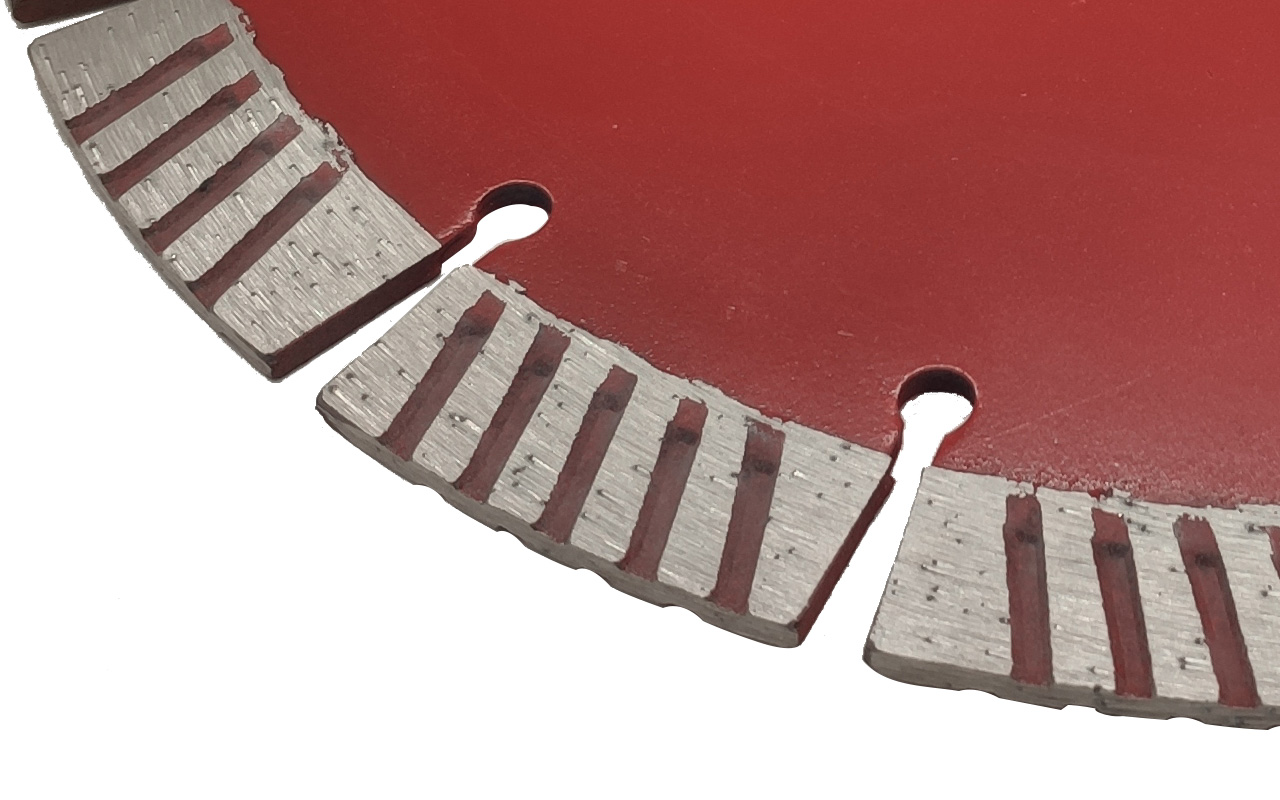

DIAMOND TOOLS

Current status of diamond tools in China

Publish Date:2020-11-09

Diamond tools are widely used in various fields such as geological prospecting, stone, machinery, automobile and national defense industry. The manufacturing technology level of abrasive tools, geological drill bits and stone sawing tools for mechanical processing has been greatly improved. The products have been serialized and standardized, with complete varieties and specifications, and stable product quality. Some products have certain competitiveness in the international market. The vast majority of diamond single crystals are used to make various types of diamond tools. The diamond sawing tools produced in my country have complete varieties and specifications and stable quality. According to statistics, in recent years, diamond drilling tools can basically meet market demand; with the development of the construction industry and the popularization of household air conditioners, they are used for pipeline installation, air conditioning machine installation and old building renovation, and diamond thin-wall engineering drill bits for construction are required The quantity is also increasing, and the demand for PDC drill bits used for petroleum and coal exploration has also increased correspondingly. The quality of the diamond composites produced in China is not good enough. Further research and improvement are needed to continuously improve product quality and change the current PDC. The situation in which drill bits rely on imports.

In mechanical processing, diamond grinding wheels, PCD tool cutters, honing stones, dressing rollers, wire drawing dies, etc. have been widely used; the performance of diamond polycrystalline wire drawing dies is better than natural diamond dies and cemented carbide dies, so it is used in the wire drawing industry Many, especially the emergence of CVD diamond wire drawing dies, provide reliable wire drawing tools for controlling wires below 15mm. PCD tools are mainly used for the processing of non-ferrous metals and non-metal materials. According to reports, the demand for PCD tools in industries such as automobiles, motorcycles, household appliances, wood processing and general machinery has increased year by year. Although the various diamond tools produced in my country have been widely used in various industries and have achieved significant economic benefits, there is still a certain gap in their technical level compared with similar foreign products, mainly in:

(1) The entire diamond tool industry lacks unified management and macro-control. Due to blind development, the entire diamond tool production layout is scattered and blooming everywhere. The tool sales market has unstable product quality, disorderly competition and chaotic prices.

(2) Due to the uncoordinated development of diamond single crystal production and diamond tool production, the development of diamond tools in China lags behind the growth rate of diamond single crystal production, resulting in diamond backlogs and slow sales, affecting and restricting the sustainable development of my country’s diamond industry. The economic benefits of diamond production enterprises have seriously declined.

(3) The application field of diamond tools is narrow, the product variety is single, the quality is unstable, and some product technical quality standards are chaotic, and there is no unified management norms and standards for product quality testing and supervision.

(4) The production equipment and overall technical level of diamond tools are relatively backward, and the popularization and application of some more advanced new technologies and processes is slow.

(5) The scale of production enterprises is generally small, production is not concentrated, process technology is poor, lack of market competitiveness, and economic benefits are not high.

(6) Insufficient capital investment in diamond tool production, new product development, process technology research, etc.

(7) During the use of diamond tools, the use rate of matrix materials is low, and the waste of steel is serious; there are more abnormal wear, shedding, and residual diamonds during use, which makes the actual utilization rate of diamonds lower and more diamond material waste.

Tags:

Use of brazing technology in diamond tool processing

2020-04-27

This article briefly introduces diamond tools, tool classification, and brazing technology used in t...

Aspects of diamond tool performance improvement

2020-03-06

Diamond tool materials have been widely used in construction, building materials, petroleum, geology...

Summary of diamond tools for stone cutting

2020-09-09

Diamond cutting tools are a very important product of diamond tools, especially important in the stone industry. From mining to the production of final stone products, they will definitely be applied to use these sawing products. Understanding the sawing products can help us better understanding the stone processing technology and the latest stone processing information....

The development direction of diamond tools in the natural stone and civil engineering industries

2020-05-27

Abstract: Metal-bonded diamond tools were introduced in the natural stone and civil engineering industries for processing decades ago. Undoubtedly, their use has brought revolutionary changes to material removal and increased processing productivity. However, although tool performance has improved significantly However, the main factor limiting the widespread use of diamond tools is the high price. Therefore, it is particularly important to fully understand the principle and grinding performance of turning. It is true that one can predict the best processing conditions, but the grinding process Cutting knowledge is the most basic condition to achieve the best machining size and improve diamond performance. This article gives a brief overview of the processing principle and related tool and process design. Considering the stone and civil engineering industry, some diamond tool development directions are also done. Briefly described....

Concept of diamond tools concentration

2020-09-02

The volume ratio of diamond in the matrix is called the concentration, and the concentration can reach up to 400%, but this is an ideal situation. For most diamond tools, the concentration of 300% is already considered as the limit. At present, The concentration of brazing products is the highest....

Current status of diamond tools

2020-08-17

Diamond tools are widely used in various fields such as geological prospecting, stone, machinery, automobiles and national defense industries. The manufacturing technology of abrasive tools, geological drill bits and stone sawing tools for mechanical processing has been greatly improved.

...

RETURN

RETURN