YOU ARE HERE >

HOME >

DIAMOND TOOLS

Summary of diamond tools for stone cutting

Publish Date:2020-09-09

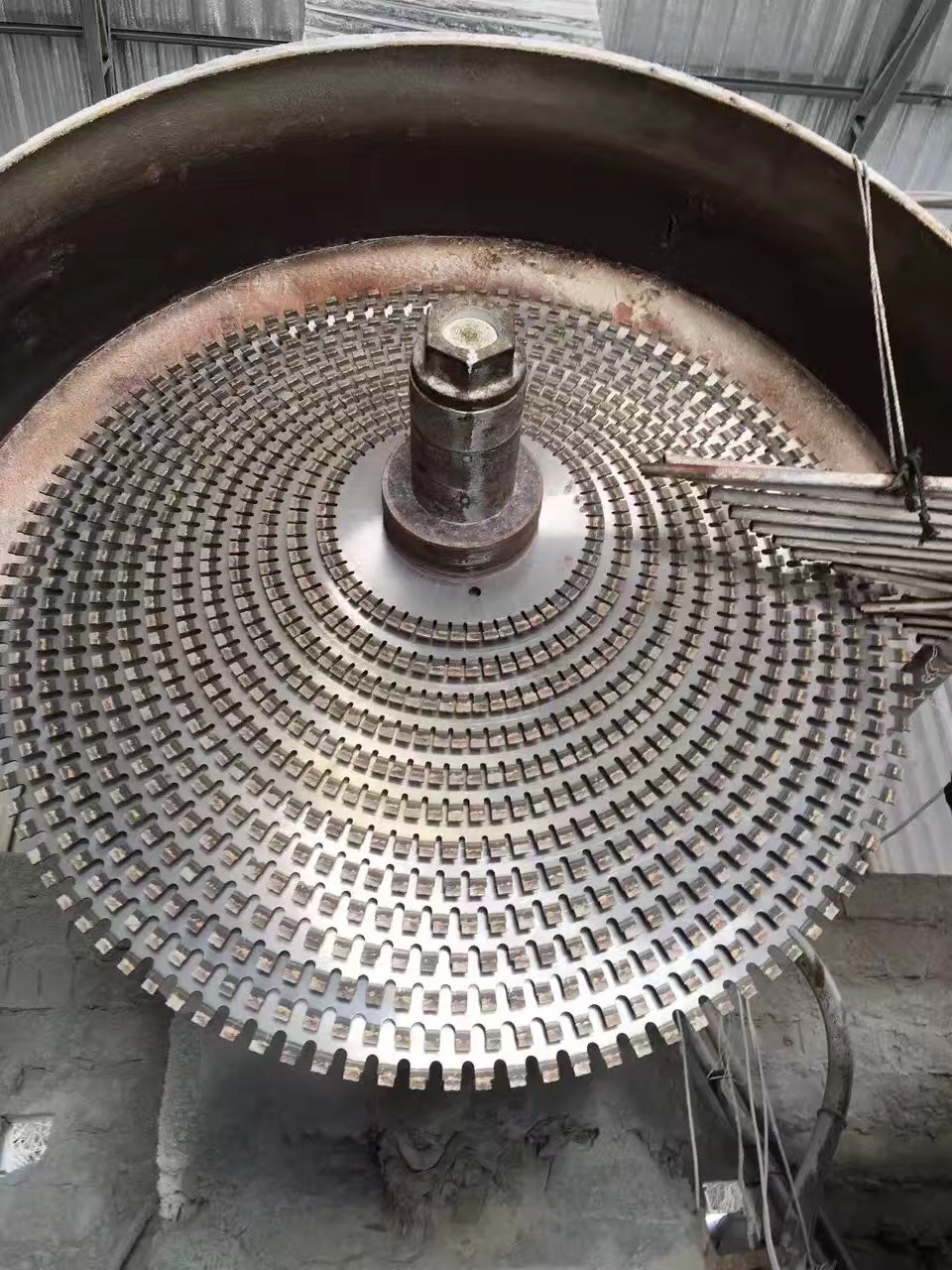

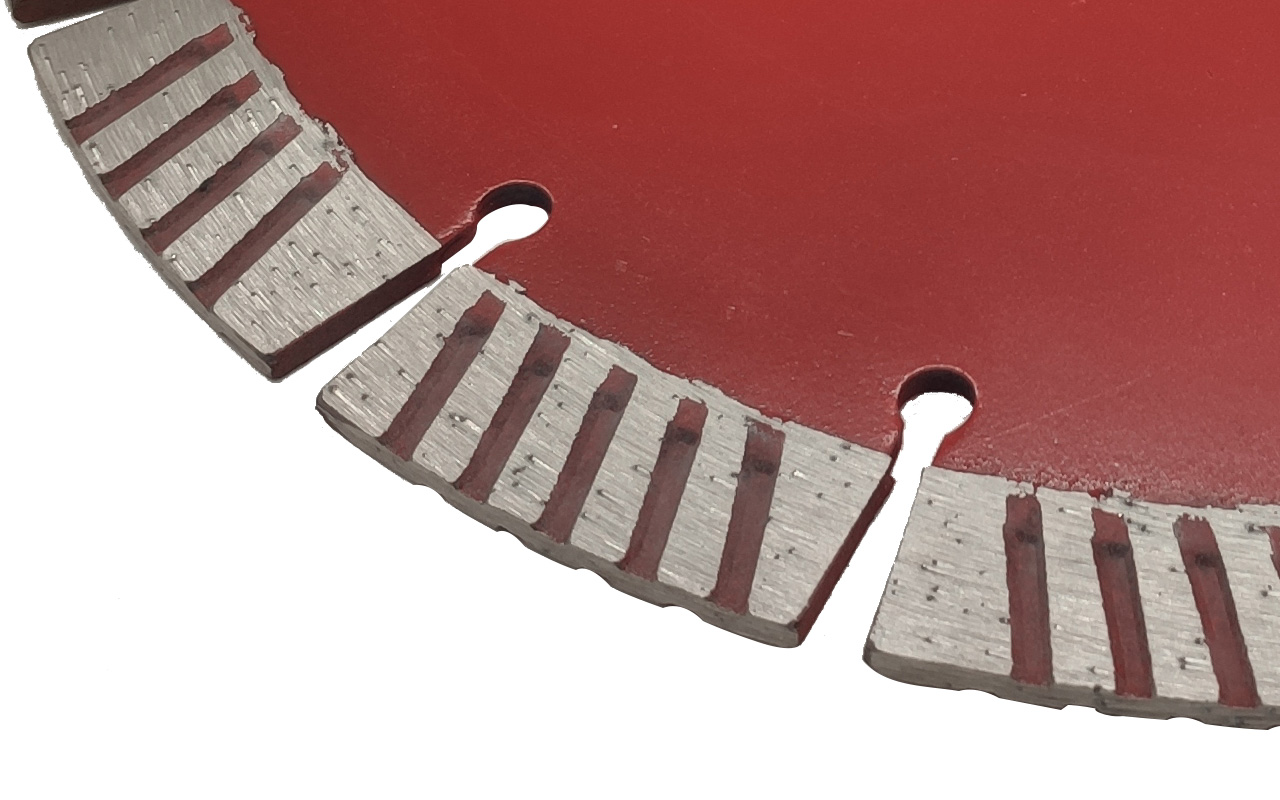

Stone cutting is a very important process in the stone processing. Cutting includes mining, shaping, special-shaped, slab cutting, tile cutting, etc. Let's learn more about the most common stone cutting tools:First: Circular saw blades, from the smallest diameter of 105mm saw blade to the largest diameter of 3500mm saw blade, covering the entire process of stone processing, from mining to interior decoration, circular saw blades are almost ubiquitous, circular saw blades selection are mainly based on different scenarios and stone materials, from marble, granite, to reinforced concrete, ceramic tiles, you can find saw blades that can match the application scenarios

Second: Gang saw

Gang saw blades are generally installed on reciprocating sawing machines (also known as frame saws and gang saws) for cutting blocks. Since the reciprocating motion of the gang saw is not conducive to the grip of the diamond particles by the matrix, it is more difficult to manufacture than the circular saw blade, and it is mainly use for cutting soft stone like marble. it has the advantages of high efficiency and low labor intensity.

Third: Diamond Wire saw

The wire saw is made up of a lot of bead stringed on a steel wire rope. Wire saws are mainly used for mining and squaring stone block. multiwire saws are used for cutting blocks, and can also be used for single wire saws for processing special-shaped stones. The method is to first drill a hole on the mining surface, insert the wire saw into the hole, connect the two ends firmly, and set it on the wheel driven by the power machine. The wheel drives the wire saw to rotate, and the rock is cut side by side. The method saves stone, and the wire saw can be bent according to it, so there is a great advantage in processing special-shaped products.

Fourth: line saw

The line saw is a simple hand sawing tool made by coating diamond powder on steel wire. Mainly used for cutting jade and stone crafts. This kind of tool has low cutting efficiency and high loss, but it saves stone and is suitable for high-value stone processing.

Fourth: wire saw

The wire saw is a simple hand sawing tool made by coating diamond powder on steel wire. Mainly used for cutting jade and stone crafts. This kind of tool has low cutting efficiency and high loss, but it saves stone and is suitable for high-value stone processing.

Fifth: Chain saw

Chain saws use holder to embed PDC on the cutting chain. They are generally used for chain arm saw mining. At present, chain saws are not widely used in the world, and they are still in the initial stage of development.

Tags:

Use of brazing technology in diamond tool processing

2020-04-27

This article briefly introduces diamond tools, tool classification, and brazing technology used in t...

Aspects of diamond tool performance improvement

2020-03-06

Diamond tool materials have been widely used in construction, building materials, petroleum, geology...

Summary of diamond tools for stone cutting

2020-09-09

Diamond cutting tools are a very important product of diamond tools, especially important in the stone industry. From mining to the production of final stone products, they will definitely be applied to use these sawing products. Understanding the sawing products can help us better understanding the stone processing technology and the latest stone processing information....

The development direction of diamond tools in the natural stone and civil engineering industries

2020-05-27

Abstract: Metal-bonded diamond tools were introduced in the natural stone and civil engineering industries for processing decades ago. Undoubtedly, their use has brought revolutionary changes to material removal and increased processing productivity. However, although tool performance has improved significantly However, the main factor limiting the widespread use of diamond tools is the high price. Therefore, it is particularly important to fully understand the principle and grinding performance of turning. It is true that one can predict the best processing conditions, but the grinding process Cutting knowledge is the most basic condition to achieve the best machining size and improve diamond performance. This article gives a brief overview of the processing principle and related tool and process design. Considering the stone and civil engineering industry, some diamond tool development directions are also done. Briefly described....

Concept of diamond tools concentration

2020-09-02

The volume ratio of diamond in the matrix is called the concentration, and the concentration can reach up to 400%, but this is an ideal situation. For most diamond tools, the concentration of 300% is already considered as the limit. At present, The concentration of brazing products is the highest....

Current status of diamond tools

2020-08-17

Diamond tools are widely used in various fields such as geological prospecting, stone, machinery, automobiles and national defense industries. The manufacturing technology of abrasive tools, geological drill bits and stone sawing tools for mechanical processing has been greatly improved.

...

RETURN

RETURN