YOU ARE HERE >

HOME >

DIAMOND TOOLS

Vacuum brazed diamond tools

Publish Date:2020-09-09

Vacuum brazed diamond tools use diamond surface metallization technology to weld diamond with active brazing filler metal or nickel-based brazing filler metal, and form elements or alloys through strong carbides to achieve chemical metallurgical bonding between diamond and tool matrix, which greatly improves the control of diamond force. In addition, the diamond can protrude 2/3, and it is not easy to fall off, and it creates favorable conditions for sharp cutting and good chip removal. In addition, it is easy to combine with the diamond orderly arrangement technology to realize a reasonable and regular distribution of diamond on the surface of the tool, making full use of the cutting effect of diamond, which can save diamond consumption, reduce tool costs, and improve cutting efficiency.The products of vacuum brazed diamond tools are mainly divided into several types of tools such as cutting, grinding, drilling, carving, etc. The following is a detailed introduction to common vacuum brazed diamond tools:

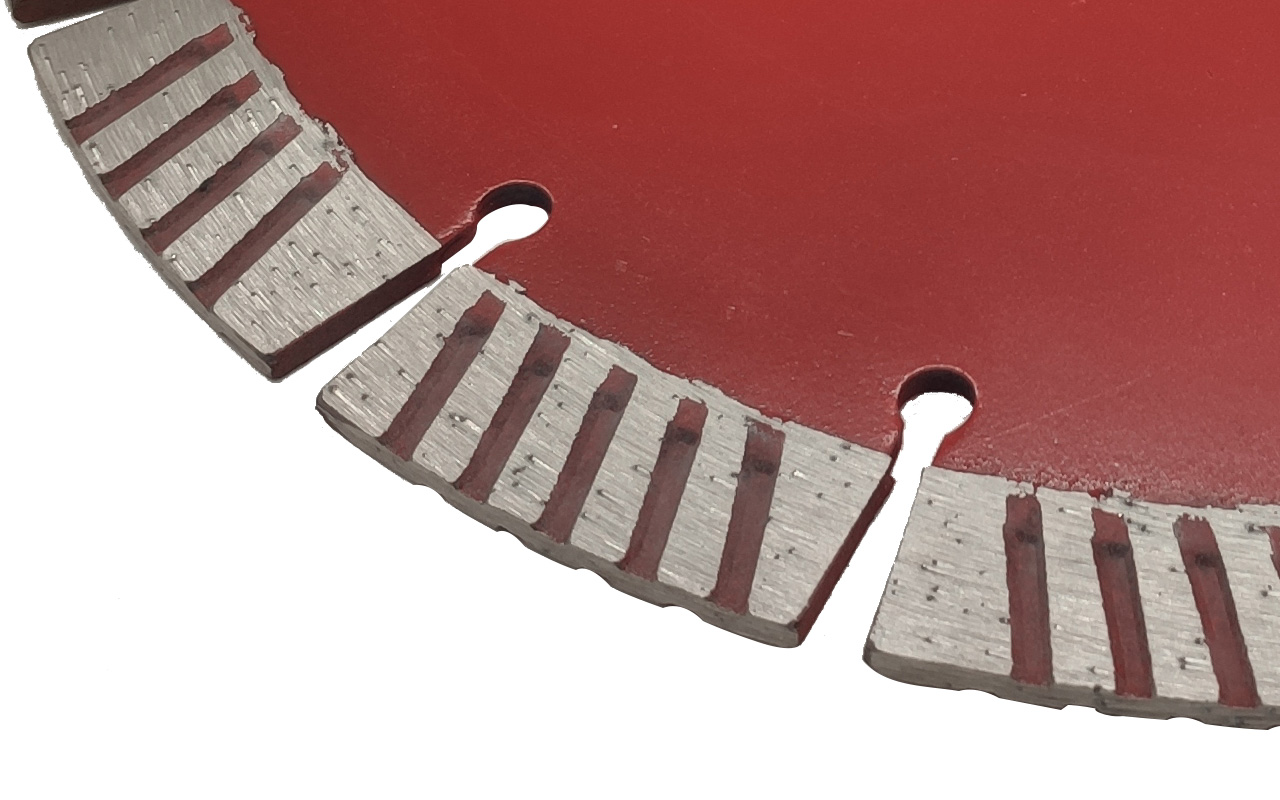

Cutting: vacuum Brazed diamond saw blades, it generally divided into traditional stone cutting blades and concrete & asphalt blades. Such tools are mainly used for dry cutting or wet cutting. Generally, the service life of wet cutting is higher than that of dry cutting. Vacuum brazing saw blades stand out with high efficiency and are often used in scenarios that require higher efficiency, such as cutting building materials during rescue operations. In addition to the saw blade, there is also a vacuum brazed wire saw. Compared with the traditional sintered wire saw, the brazed wire saw is more efficient and has better processing efficiency when cutting marble.

Grinding: vacuum brazed diamond tools can also be used for stone grinding, such as brazed bowl grinding for grinding, brazed cutting wheels for grooving, various CNC tools for special-shaped processing (logic wheels, positioning wheels, leveling wheels, Finger drills, milling cutters, etc.).

Drilling: Vacuum Brazed drill bits are often used for core drilling. Brazed diamond drills are more efficient and are widely used in high-end stone finishing.

Carving bit: Compared with traditional carving bit, brazed carving bis have more shapes, more styles, faster processing efficiency, and more detailed parts can be processed.

There are two main types of brazing equipment currently in use. One is high frequency induction welding machine; the other is high temperature vacuum furnace.

Tags:

Use of brazing technology in diamond tool processing

2020-04-27

This article briefly introduces diamond tools, tool classification, and brazing technology used in t...

Aspects of diamond tool performance improvement

2020-03-06

Diamond tool materials have been widely used in construction, building materials, petroleum, geology...

Summary of diamond tools for stone cutting

2020-09-09

Diamond cutting tools are a very important product of diamond tools, especially important in the stone industry. From mining to the production of final stone products, they will definitely be applied to use these sawing products. Understanding the sawing products can help us better understanding the stone processing technology and the latest stone processing information....

The development direction of diamond tools in the natural stone and civil engineering industries

2020-05-27

Abstract: Metal-bonded diamond tools were introduced in the natural stone and civil engineering industries for processing decades ago. Undoubtedly, their use has brought revolutionary changes to material removal and increased processing productivity. However, although tool performance has improved significantly However, the main factor limiting the widespread use of diamond tools is the high price. Therefore, it is particularly important to fully understand the principle and grinding performance of turning. It is true that one can predict the best processing conditions, but the grinding process Cutting knowledge is the most basic condition to achieve the best machining size and improve diamond performance. This article gives a brief overview of the processing principle and related tool and process design. Considering the stone and civil engineering industry, some diamond tool development directions are also done. Briefly described....

Concept of diamond tools concentration

2020-09-02

The volume ratio of diamond in the matrix is called the concentration, and the concentration can reach up to 400%, but this is an ideal situation. For most diamond tools, the concentration of 300% is already considered as the limit. At present, The concentration of brazing products is the highest....

Current status of diamond tools

2020-08-17

Diamond tools are widely used in various fields such as geological prospecting, stone, machinery, automobiles and national defense industries. The manufacturing technology of abrasive tools, geological drill bits and stone sawing tools for mechanical processing has been greatly improved.

...

RETURN

RETURN