Aspects of diamond tool performance improvement

Diamond tool materials have been widely used in construction, building materials, petroleum, geology, metallurgy, machinery, electronics and other industries.In order to ensure that diamond tools do not have accidents during the production process, we should respond to the production materials of single-piece saw blade tools Make the right choice, so how do you choose the diamond tool production material to ensure quality?

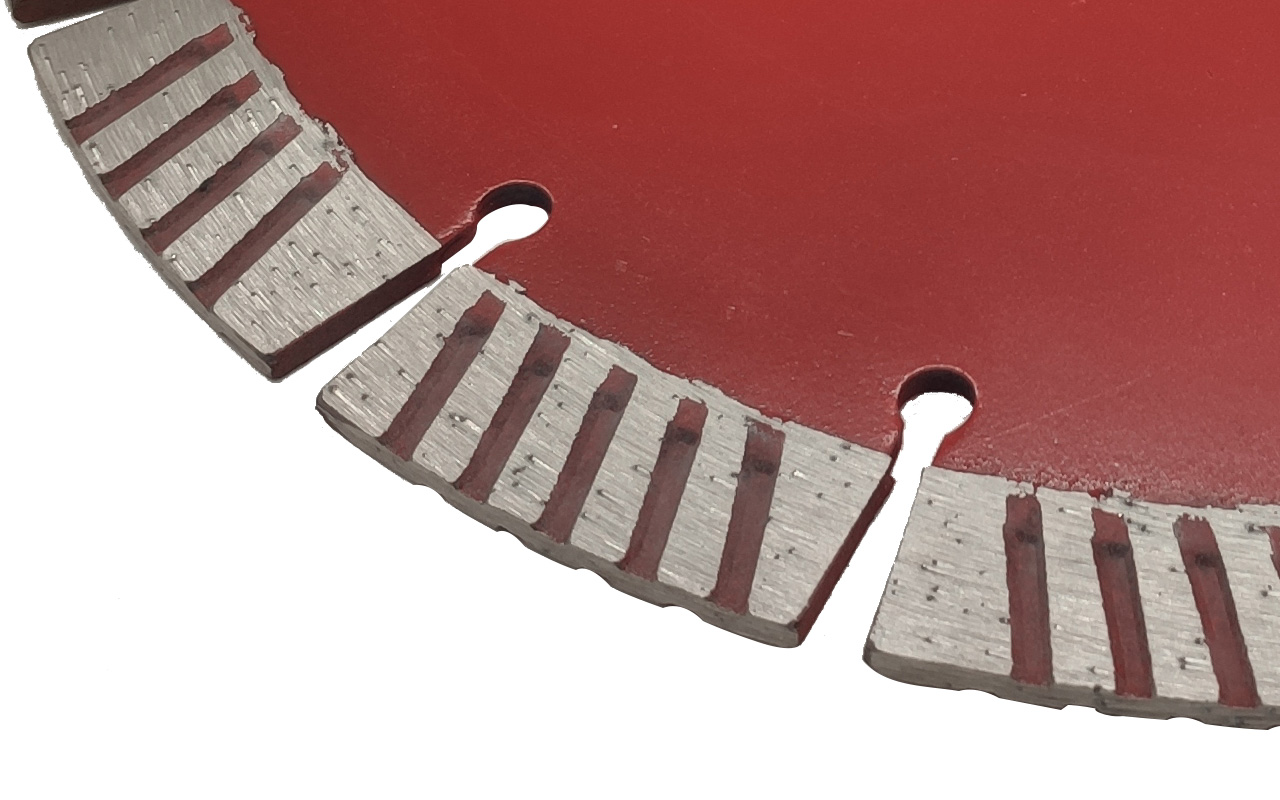

1.Using high-strength diamond with stable production performance, coarse particles and good thermal stability. Diamond tools are basically fixed on the working substrate by diamond and matrix under certain process conditions, and are mainly processed by the abrasive and cutting action of diamond Different stones. Therefore, the quality, particle size and concentration of raw materials have a decisive effect on diamond tools.

2.Although the strong carbon powder element is added to improve the diamond holding force. During the processing of the diamond tool, if the cutter body has a good holding force on the diamond, the diamond will have a good cutting edge and will not fall off prematurely. High efficiency. Because this type of powder has good wettability and affinity for diamond, it can greatly improve the holding power of the matrix to diamond.

3.Improve the particle size ratio of diamond. In the traditional ratio, the cutter head should be sharper, and more coarse-grained diamonds should be used, otherwise fine-grained diamonds are used. It is true, but it can't reach the maximum working efficiency. The modulus of elasticity is high, and plastic deformation is difficult to occur during high temperature sintering. It is beneficial to increase the wear ratio of the tool by choosing a suitable ratio and increasing the packing density of diamond particles before sintering. After several experiments, it is found that the general tool head is coarse. It consists of three kinds of diamonds: medium, coarse and fine.The ratio of particle size is 1 to 1.

4.Using ultra-fine powder and pre-alloy powder. Ultra-fine powder is beneficial to reduce sintering temperature and increase carcass hardness. Pre-alloy powder, through three-dimensional mixing, greatly shortens the contact time between powder and air and prevents low melting point. Premature metal loss and segregation will help improve the strength of sintered products and increase the holding power of diamonds.

5.Add appropriate amount of rare earth element to the carcass powder, which can obviously reduce the wear performance of the binder and improve the cutting efficiency of diamond tools.

6.The cold pressing and hot sintering process is adopted to sinter in a vacuum protective atmosphere. The sintered blade after cold pressing is very sharp in the sawing process and the production efficiency is greatly improved.The vacuum protective atmosphere sintering can prevent powder oxidation. Activated sintering not only improves the performance of the cutter head, but also extends the life of the graphite mold, and can also reduce production costs.

7, the correct welding process, the current diamond garden saw blades are welded with high-frequency welding machine, welding is very prone to the secondary "burn" and drop-out phenomenon of the blade. Not only unsafe, but also affect production, so it should be High-strength, good-permeability silver solder pads are used for welding processing production.

Use of brazing technology in diamond tool processing

Aspects of diamond tool performance improvement

Summary of diamond tools for stone cutting

The development direction of diamond tools in the natural stone and civil engineering industries

Concept of diamond tools concentration

RETURN

RETURN