YOU ARE HERE >

HOME >

DIAMOND WIRE

Diamond wire saw wire steel wire and connectors

Publish Date:2020-10-16

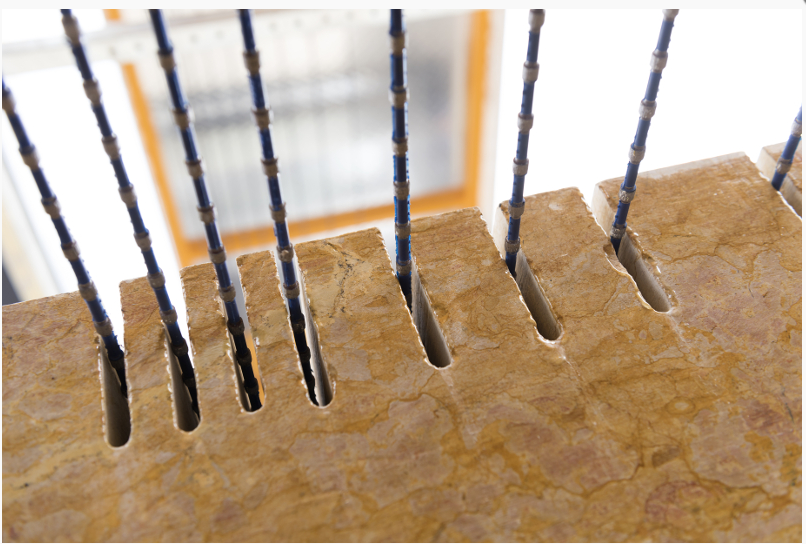

The diamond wire saw is a rope-shaped cutting tool that combination of soft and hard. Compared with the previous extremely rigid sawing products, the diamond wire saw has a processing principle of overcoming strength with softness.During cutting process, the wire saw is straightened by the wire saw machine, and the wire saw is rotated at a high speed, so that the wire saw and the cutting material form different curved shapes. The wire saw maintains the cutting pressure during the cutting process to maintain cutting efficiency.

As the carrier of diamond beads, the steel wire has a significant impact on the cutting performance of the wire saw. If the life of the steel wire is short and broken frequently, the cutting performance of the diamond wire saw cannot be reflected, and the broken steel will cause great danger. Steel wire are also particular about rigidity and flexibility. For example, if the rigidity is too high, the wire rope will easily break if the wire rope is excessively bent. If the wire rope is too flexible, too much flexibility will cause the wire rope to become thinner or deformed, resulting in the entire wire saws are can’t use. Therefore, the steel wire is very important for the diamond wire saw, which can directly determine the life and cutting efficiency of the wire saw.

The early steel wire used cable steel wire, high strength, but insufficient flexibility, such a wire saw has a small chance of breaking the rope, and the cost is also very low. However, this kind steel wiree is not flexible enough. When cutting special-shaped stone or cutting small surface stone, Deformation and bending of the wire saw will occur.

In consideration of rigidity and flexibility, the steel wire must provide a longer service life, preferably higher than the service life of the beads. After a long-term study, it is found that to increase the service life of the steel wire, the fatigue strength should be increased. Among all the mechanical properties of the steel wire, the key indicator is the fatigue strength. Take D9.5mm wire saw with for example, the length is 14.8m with cutting speed 30m/s. Every time the wire saw rotates, it changes from bend to straight, and from straight to bend alternately loops twice. The use time of a wire saw is about 500-1000h (varies depending on the cutting size the cutting object), at least 3.8 million cycles, and more than 7 million cycles of bending and straightening. What's more, when the wire saw is used, high-frequency vibration may occur due to the unstable operation of the machine. Therefore, the steel wire must have a higher fatigue strength to meet the requirements of the wire saw.

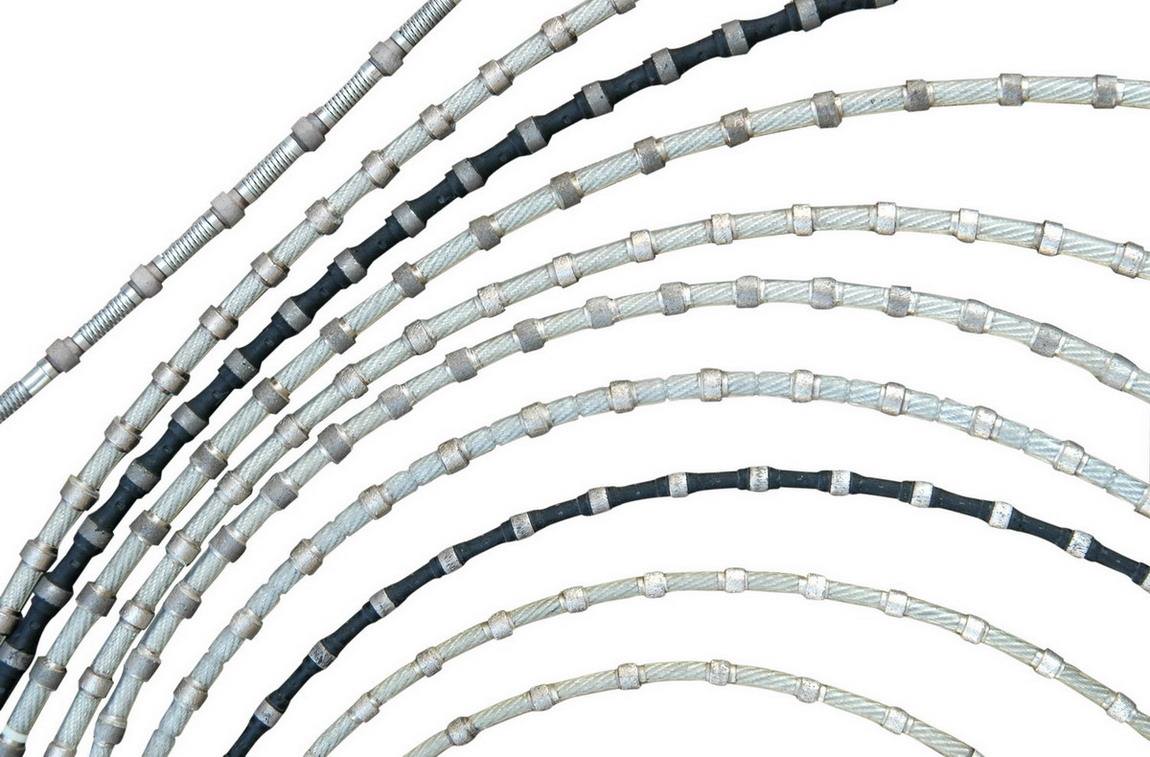

After talking about the steel wire, the connectors piece are also very important. it is related to the bead fixing technology. The common bead fixing methods include spring fixing, plastic or rubber fixing, spring + plastic or rubber composite fixing. Let's take a look at the usage of these connectors.

Spring fixed wire saws are mostly used for marble mining, and plastic wire saws are mainly used for shaped stone shaping and block cutting. Rubber rope is mainly used for granite mining, and springs and rubber are mostly used for domestic marble mining and block shaping. The spring + plastic is mostly used for the shaping of domestic blocks.

Tags:

Comparison of brazed diamond wire saw and electroplated wire saw

2020-10-16

The brazed diamond wire saw is to fix the diamond to the bead steel base by brazing. This is the third form of the wire saw since diamond wire saw birth in 1977. The earliest is the electroplated diamond wire saw, and the second is the sintered diamond wire saw. The brazed diamond wire saw is the third form. Compared with the earliest electroplated wire saw, this form has many improvements. This article mainly distinguishes the difference between the two through these obvious performance improvements....

Reasons for diamond wire saw broken

2020-12-29

During diamond wire saw cutting process of the, it is under extreme conditions such as high temperature, high pressure, strong tension, and strong bending. The steel wire is fatigued and the diamond wire is broken. Then what are the specific reasons that can affect the broken the diamond wire saw?...

Diamond wire saw classification

2020-12-14

Diamond wire saw is a kind of modern sawing tool. For cutting hard materials, it has the characteristics of small kerf and high efficiency, especially in cutting concrete and stone. Because the wire saw is a flexible cutting material, it is processing angle can be adjusted at any time and is currently widely used in the world. This article mainly introduces the classification of diamond wire saw products to let everyone better understand the wire saw products....

Advantages of diamond wire saw

2020-10-16

Compared with sawing tools, diamond wire saws have many advantages, such as higher cutting efficiency, more shapes of cut stones, and more thickness and randomness of cut stones. In addition, diamond wire saws can process all kinds of special-shaped stones, such as arc plates, which cannot be processed by saw blades. This article mainly combines the processing characteristics of diamond wire saws to let you know about diamond wire saws and their advantages....

Common problems of diamond wire saw

2020-10-16

Diamond wire saw is a new type of stone cutting tool. The wire saw has the characteristics of high efficiency, larger cutting surface, cutting angle adjustable and long service life. However, there are many problems in the cutting process. This article provides related solutions for the common problems of diamond wire saws....

How to use diamond wire saw correctly

2020-12-14

Diamond bead wire saw, also known as diamond wire saw, is a diamond tool based on high-quality steel wire rope, which is fixed with plastic, spring or rubber connecting pieces on the outside of the wire rope. It is mainly used for stone and concrete cutting. In the actual operation process, there are many safety precautions that need to be paid attention to in the diamond wire saw....

RETURN

RETURN