YOU ARE HERE >

HOME >

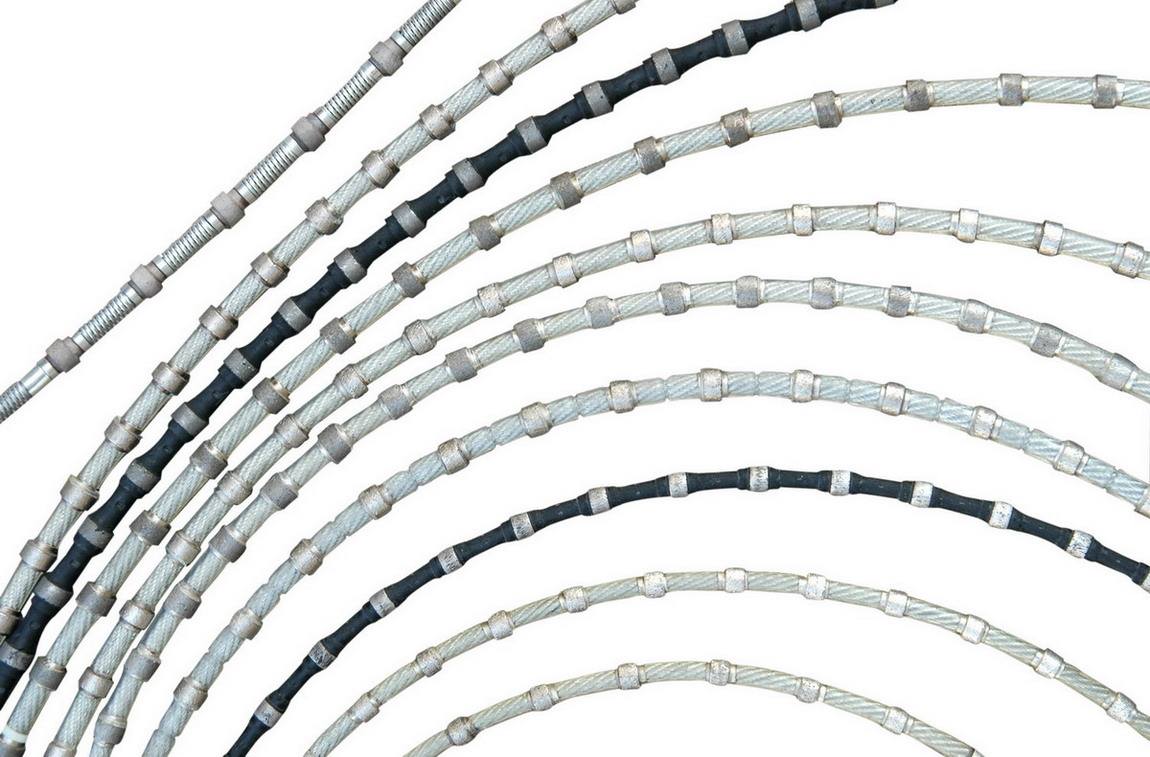

DIAMOND WIRE

The advantages of diamond wire saws for stone mining and cutting

Publish Date:2020-12-31

As a relatively new stone mining and processing tool, diamond wire saws have many advantages, such as small cutting gap, arbitrarily adjustable incisions, and the ability to mine large materials. These advantages gradually make diamond wire saws begin to occupy a dominant position in stone processing. Let’s take a closer look:

1. Diamond wire saws are mainly divided into mining wire saws, profile cutting wire saws, multiwire saws and block dressing wire saws. These wire saws are connected with beads of different diameters and different connectors to meet various cutting requirements. Almost all cutting stone processing can be applied, such as mining, cutting blocks into slab, cutting large slab into size tiles and so on.

2. Diamond wire saws can be adjusted according to the characteristics and hardness of the stone. At present, large wire saw manufacturers can adjust the formula to produce the diamond wire saw according to different stone types (applicable to granite, marble, limestone, sandstone, basalt, Andesite, etc. )

3. The diamond wire saw is a flexible cutting tool, and the process is also the most advanced processing technology. Especially in recent years, increasingly thinner wire saws have been continuously developed. For processing blocks byb multiwire saws, it is even more important. It saves materials, especially when cutting expensive blocks, the value of the saved stones is much higher than the use cost of the sawing tool.

4. At present, most of the wire saw machines use automatic cutting equipment. Compared with the previous blasting mining and saw blade cutting stone, the wire saw processing stone is undoubtedly more labor-saving, allowing machinery to replace labor, reducing human errors, and making cutting more Stable to ensure that the stone slab is more smooth.

5. The diameter of the diamond wire saw bead is gradually decreasing, especially for the cutting of blocks, from the earliest diameter of 8.8mm to the diameter of 7.2mm, the commonly used combination wire saw has reached 6.3mm or even 5.4mm. The reduction in diameter has a direct effect on saving stone, and one block can produce more stone.

6. When the diamond wire saw is used to cut stone, it can be used to adjust the cutting angle and cutting depth with a computer, and can complete the cutting process of various angles such as horizontal, vertical, inclined, arc, and corner. From the perspective of block mining, all kinds of blocks can be cut to meet customers' different requirements for stone block sizes.

7. The diamond wire saw combined with a high-power wire saw can quickly process stone. Whether it is mining or processing blocks, the high power of the wire saw can provide a constant sawing pull.

8. In the process of mining stone, the mine wire saw can process large blocks with a cross-section of hundreds to thousands of square meters and a block volume of tens of cubic meters or even hundreds of cubic meters. Such blocks are very rare. With a wire saw, other mining methods can hardly get such large stones.

9. Because the mine wire saw machine is very small in size and takes up almost no space, the wire saw can also be used for mining in relatively harsh mining conditions.

10. In addition to processing stone, the wire saw can also be used to cut reinforced concrete, such as demolition of old buildings, bridge removal, etc., especially for the cutting of bridge piers below the water surface, it is irreplaceable.

Tags:

Comparison of brazed diamond wire saw and electroplated wire saw

2020-10-16

The brazed diamond wire saw is to fix the diamond to the bead steel base by brazing. This is the third form of the wire saw since diamond wire saw birth in 1977. The earliest is the electroplated diamond wire saw, and the second is the sintered diamond wire saw. The brazed diamond wire saw is the third form. Compared with the earliest electroplated wire saw, this form has many improvements. This article mainly distinguishes the difference between the two through these obvious performance improvements....

Reasons for diamond wire saw broken

2020-12-29

During diamond wire saw cutting process of the, it is under extreme conditions such as high temperature, high pressure, strong tension, and strong bending. The steel wire is fatigued and the diamond wire is broken. Then what are the specific reasons that can affect the broken the diamond wire saw?...

Diamond wire saw classification

2020-12-14

Diamond wire saw is a kind of modern sawing tool. For cutting hard materials, it has the characteristics of small kerf and high efficiency, especially in cutting concrete and stone. Because the wire saw is a flexible cutting material, it is processing angle can be adjusted at any time and is currently widely used in the world. This article mainly introduces the classification of diamond wire saw products to let everyone better understand the wire saw products....

Advantages of diamond wire saw

2020-10-16

Compared with sawing tools, diamond wire saws have many advantages, such as higher cutting efficiency, more shapes of cut stones, and more thickness and randomness of cut stones. In addition, diamond wire saws can process all kinds of special-shaped stones, such as arc plates, which cannot be processed by saw blades. This article mainly combines the processing characteristics of diamond wire saws to let you know about diamond wire saws and their advantages....

Common problems of diamond wire saw

2020-10-16

Diamond wire saw is a new type of stone cutting tool. The wire saw has the characteristics of high efficiency, larger cutting surface, cutting angle adjustable and long service life. However, there are many problems in the cutting process. This article provides related solutions for the common problems of diamond wire saws....

How to use diamond wire saw correctly

2020-12-14

Diamond bead wire saw, also known as diamond wire saw, is a diamond tool based on high-quality steel wire rope, which is fixed with plastic, spring or rubber connecting pieces on the outside of the wire rope. It is mainly used for stone and concrete cutting. In the actual operation process, there are many safety precautions that need to be paid attention to in the diamond wire saw....

RETURN

RETURN