YOU ARE HERE >

HOME >

DIAMOND WIRE

Reasons for diamond wire saw broken

Publish Date:2020-12-29

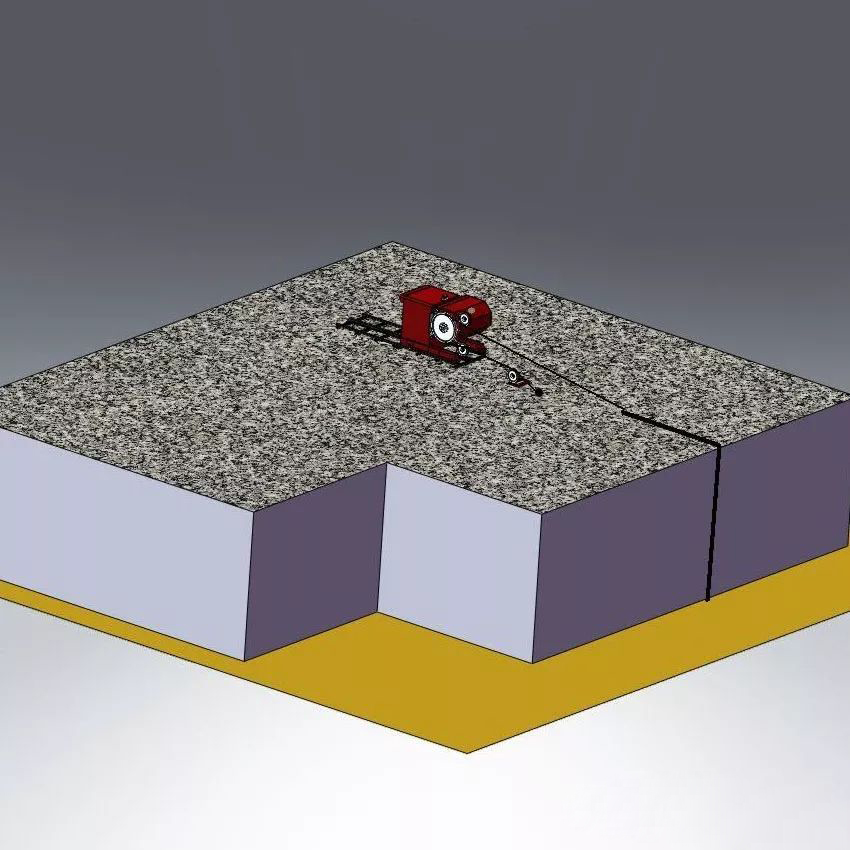

Breaking of other parts in the middle of the wire rope except the diamond wire saw joint is called broken diamond wire saw. In the process of using the diamond wire saw, the rope may be broken. This situation can actually be avoided, or we can deal with it in advance.

After years of experience, Xiamen Super Cut Tool Co., Ltd has summarized the following reasons for the broken rope of the wire saw:

Steel wire rope is used as a beaded carrier, and its service life restricts the service life of the wire saw. Calculated according to the 14.85m profile cutting wire saw, from the beginning of use to the scrap of the wire saw, the use time reaches more than 600H, and its linear speed is 22m/s, then the steel wire rope must be cycled more than 3×106 times under the premise that the wire rope bears the alternating load during the service cycle , It will easily cause the fatigue fracture of the steel wire rope; after the joint is crimped, it will cause certain damage to the wire rope, which will cause the steel wire rope at the joint to break prematurely. Therefore, we must choose extremely excellent steel wire rope.

In addition, the following conditions during use will also cause the wire rope to break prematurely:

1:Due to the machine problem, the wire saw is not running smoothly and frequently shakes, which will easily cause the diamond wire saw break frequently;

2:Due to the manufacturer's reasons, the beads are not firmly fixed, and the beads turn or move. After the beads are rotated, the wire rope will be broken in a short time;

3:If the connection part is too tightly crimped, it will increase the damage of the wire rope and cause the wire rope at the joint to break prematurely;

4:Customers one-sided pursuit of cutting efficiency and forced feeding down, causing the wire saw to run too much arc, the tension is too large, and then cause the steel wire rope to break;

5:After using the diamond wire saw plastic injection type for a certain period of time, some cooling water and chips will be injected between the plastic and the steel wire rope. If the parking time is too long, the wire rope will rust and become brittle, and the middle of the steel wire rope will break in advance;

If the beads on the wire rope of the diamond wire saw are loose, they should be removed to avoid potential safety hazards. The diamond wire saw should be inspected before cutting. If it is found to be unqualified, it should be repaired in time.

Tags:

Comparison of brazed diamond wire saw and electroplated wire saw

2020-10-16

The brazed diamond wire saw is to fix the diamond to the bead steel base by brazing. This is the third form of the wire saw since diamond wire saw birth in 1977. The earliest is the electroplated diamond wire saw, and the second is the sintered diamond wire saw. The brazed diamond wire saw is the third form. Compared with the earliest electroplated wire saw, this form has many improvements. This article mainly distinguishes the difference between the two through these obvious performance improvements....

Reasons for diamond wire saw broken

2020-12-29

During diamond wire saw cutting process of the, it is under extreme conditions such as high temperature, high pressure, strong tension, and strong bending. The steel wire is fatigued and the diamond wire is broken. Then what are the specific reasons that can affect the broken the diamond wire saw?...

Diamond wire saw classification

2020-12-14

Diamond wire saw is a kind of modern sawing tool. For cutting hard materials, it has the characteristics of small kerf and high efficiency, especially in cutting concrete and stone. Because the wire saw is a flexible cutting material, it is processing angle can be adjusted at any time and is currently widely used in the world. This article mainly introduces the classification of diamond wire saw products to let everyone better understand the wire saw products....

Advantages of diamond wire saw

2020-10-16

Compared with sawing tools, diamond wire saws have many advantages, such as higher cutting efficiency, more shapes of cut stones, and more thickness and randomness of cut stones. In addition, diamond wire saws can process all kinds of special-shaped stones, such as arc plates, which cannot be processed by saw blades. This article mainly combines the processing characteristics of diamond wire saws to let you know about diamond wire saws and their advantages....

Common problems of diamond wire saw

2020-10-16

Diamond wire saw is a new type of stone cutting tool. The wire saw has the characteristics of high efficiency, larger cutting surface, cutting angle adjustable and long service life. However, there are many problems in the cutting process. This article provides related solutions for the common problems of diamond wire saws....

How to use diamond wire saw correctly

2020-12-14

Diamond bead wire saw, also known as diamond wire saw, is a diamond tool based on high-quality steel wire rope, which is fixed with plastic, spring or rubber connecting pieces on the outside of the wire rope. It is mainly used for stone and concrete cutting. In the actual operation process, there are many safety precautions that need to be paid attention to in the diamond wire saw....

RETURN

RETURN