-

Current status of diamond tools in China

2020-11-09Diamond tools are currently widely used in geology, stone, machinery, automobiles and national defense industries, especially diamond tools in China, the development time is not long, but a large number of high-quality diamond tool manufacturers have emerged. In terms of the industry as a whole, there are still great problems, this article seeks solutions by introducing the problems faced by China's diamond tools....

-

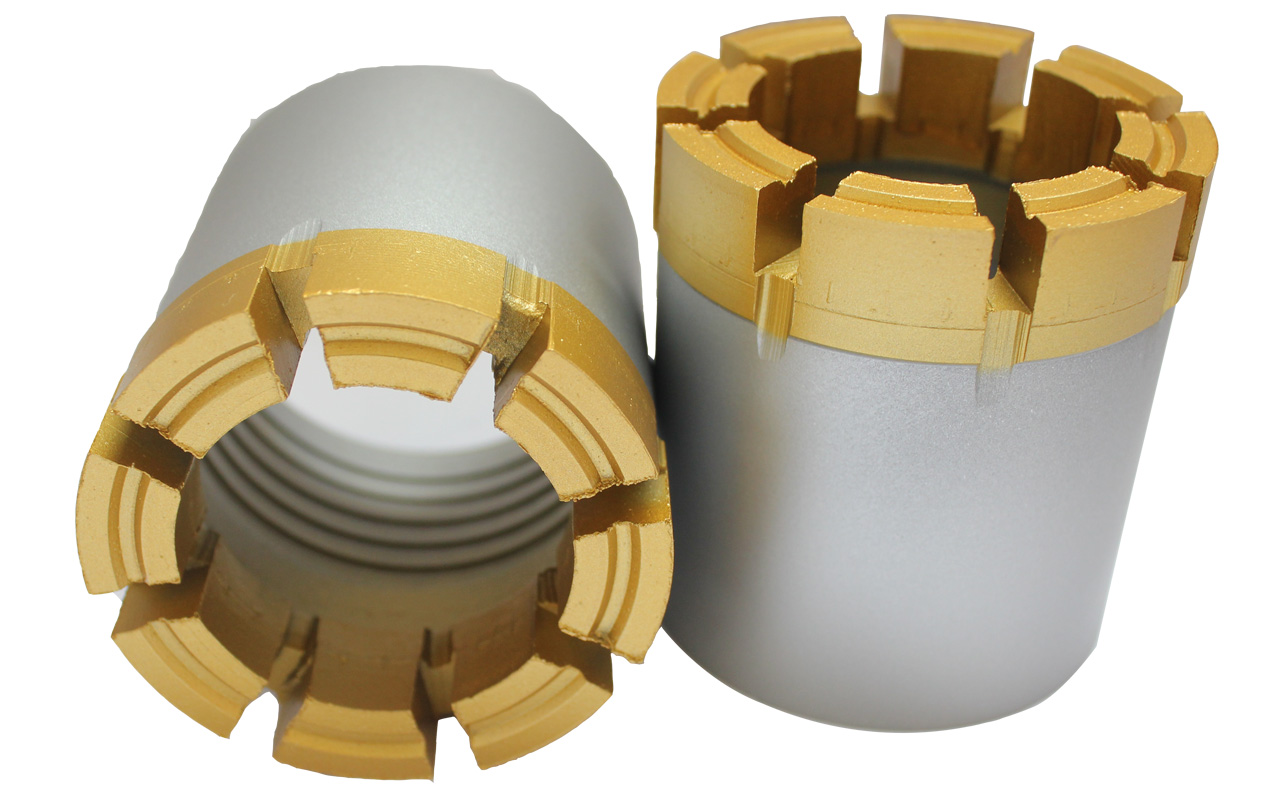

The structure of the diamond bit and cutting material

2020-11-09The diamond drill bit is composed of five parts: drill body, crown, hydraulic structure, gauge, and cutting edge, each of which has its own function. As the main part of cutting, the cutting material of the drill bit is also a very critical part. This article introduces the structure of the diamond bit and the cutting bit, so that everyone has a preliminary understanding of the diamond bit....

-

Advantages of diamond wire saw

2020-10-16Compared with sawing tools, diamond wire saws have many advantages, such as higher cutting efficiency, more shapes of cut stones, and more thickness and randomness of cut stones. In addition, diamond wire saws can process all kinds of special-shaped stones, such as arc plates, which cannot be processed by saw blades. This article mainly combines the processing characteristics of diamond wire saws to let you know about diamond wire saws and their advantages....

-

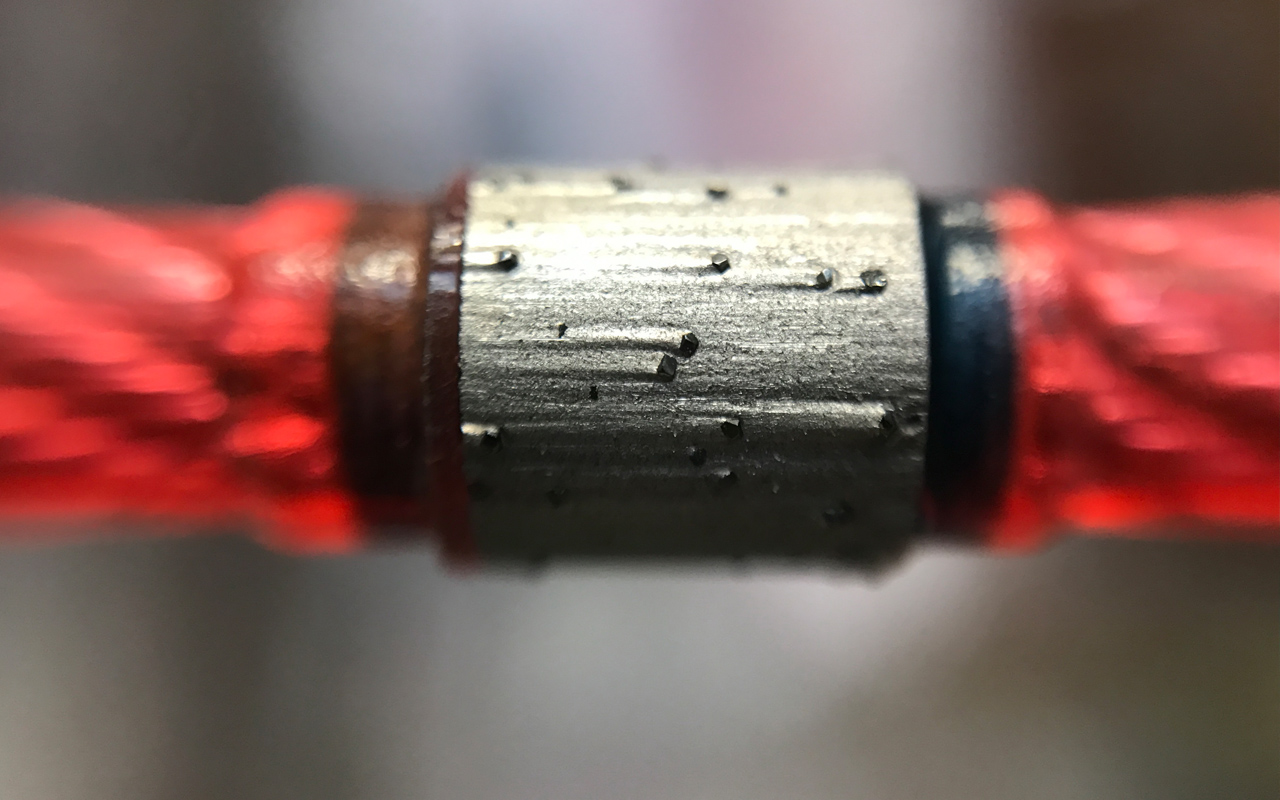

Diamond wire saw wire steel wire and connectors

2020-10-16The diamond wire saw is composed of beads, steel wire, and connectors. The core part is the beads and the steel wire. The beads are mainly used for cutting, and the steel wire is connected to the beads, so that the beads can be better cut. Of course, the part wrapped on the outside of the steel wire plays a role in protecting the steel wire and fixing the beads....

-

Comparison of brazed diamond wire saw and electroplated wire saw

2020-10-16The brazed diamond wire saw is to fix the diamond to the bead steel base by brazing. This is the third form of the wire saw since diamond wire saw birth in 1977. The earliest is the electroplated diamond wire saw, and the second is the sintered diamond wire saw. The brazed diamond wire saw is the third form. Compared with the earliest electroplated wire saw, this form has many improvements. This article mainly distinguishes the difference between the two through these obvious performance improve...

-

The development of diamond wire saw

2020-10-16Since the advent of diamond wire saws, it has been a process of continuous innovation in the manufacturing process of wire saws, as well as a process of continuous development and expansion. At present, there are more than 8,000 wire saw machines for mining marble in the world, and more than 17,000 wire saw machines for mining granite. The number of wire saws machines for block shaping and cutting is increasing. and there are also increasing cases of using wire saws in large-scale engineering re...

-

Diamond wire saw characteristics

2020-10-16The diamond wire saw has not been around for a long time, and it has a short history of 50 years from concept design to practical application. However, in the short application process, it has continuously refreshed the history of the stone processing industry. From the earliest simple tests, It has become the best tool for stone mining and block cutting, and has become the most efficient cutting tool for stone processing....

-

Common problems of diamond wire saw

2020-10-16Diamond wire saw is a new type of stone cutting tool. The wire saw has the characteristics of high efficiency, larger cutting surface, cutting angle adjustable and long service life. However, there are many problems in the cutting process. This article provides related solutions for the common problems of diamond wire saws....

-

Formula design of diamond segment

2020-10-16Diamond segment is a very special segmented product. Through different formulas and different processes, products with different appearances, different cutting performances and different cutting life can be produced. The most attractive part of this product is that it is not Certainty, especially the new formula, needs to consider factors such as the object to be processed, the matrix metal bond, diamond grade and particle size, pressure and sintering temperature....

-

Introduction of diamond fickert

2020-10-16Diamond fickert is a common abrasive used in stone polishing machinery. It is mainly composed of diamond segment and steel base. The steel base part is used to be fixed on the grinding head of the polishing machine. A grinding head can be inlaid with 6-7 pieces diamond fickert. During the operation, the diamond fickert polishes the slabs in all directions through the rotation of the grinding head on the polishing machine and the forward and backward movement of the grinding machine crossbeam....