-

Resin bond diamond fickert

2020-12-31Diamond is the main tool for grinding stone. After rough grinding the granite slab with metal bond diamond fickert, it is necessary to further process the stone that has completed the rough grinding process. At this time, the resin bond diamond fickert which made by diamond and resin bonded came into being. This kind of product performs finer grinding on the surface of granite slabs, also known as fine grinding. After fine grinding, the surface of the slab is basically flat and presents a matt s...

-

Diamond fickert production process

2020-12-31Diamond fickert is composed of steel base and fickert abrasive block. In the process of producing diamond fickert, the steel base is basically purchased from alloy steel supplier. The steel body material requires high temperature resistance and must can be formed into a compact one-piece structure with the fickert abrasive block, and the other part is the fickert abrasive block, which is also the focus of this article....

-

Diamond fickert length and style

2020-12-31The shape of the diamond fickert has already been determined in terms of styling. The main difference lies in the change of its length and the style. Generally speaking, the commonly used lengths of the diamond fickert are 130mm, 135mm, 145mm, 170mm. On the one hand, abrasive agglomeration can be divided into two types: slotted and continuous. This article mainly introduces the influence of diamond fickert different lengths and different styles of on stone processing....

-

Granite Polishing Products-Metal bond diamond fickert afickertsive

2020-12-31Diamond fickert is a product used in the automatic granite polishing line. It is mainly used in fickert-type polishing machine. The biggest feature of this machine is that there are 6-7 firkets installation grooves on the bottom of the polishing head. It is used for rough grinding of granite slabs, so it is placed at the front of the granite polishing line, and the front is connected with the califickertting afickertsives....

-

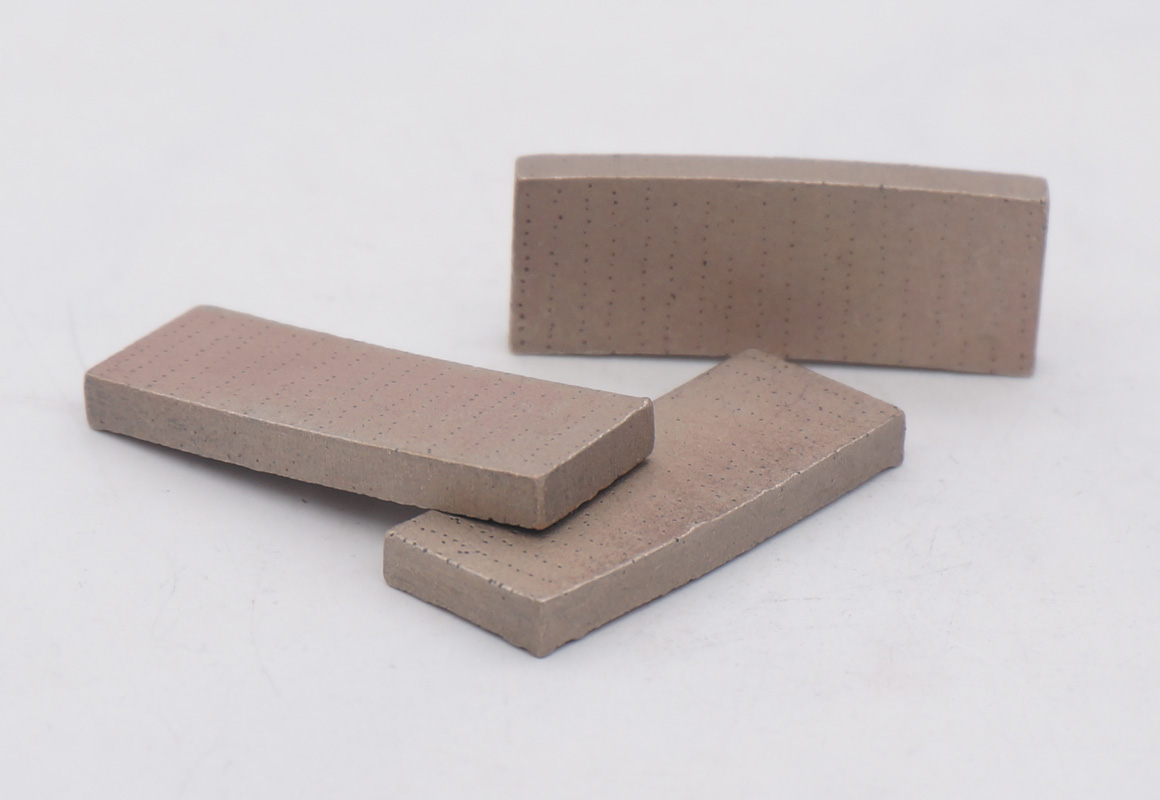

Detailed description of diamond segment manufacturing

2020-12-29The most important thing in the production and shaping of diamond segment is the selection of materials and the sintering process. These two processes seem to be divided into front and back, but in fact the two are mutually matched and mutually achieved. The selection of materials must be matched with the appropriate sintering process. For different materials, the sintering process will also change accordingly....

-

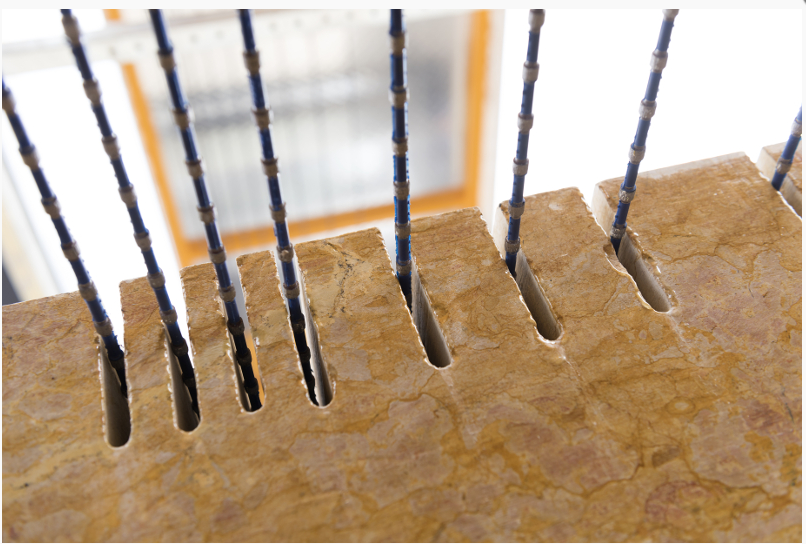

Arrayed diamond segment and the saw blade

2020-12-29In traditional diamond segment products, the diamond powder in the segment is arranged in disorder. During the cutting process, the exposed diamond will impact the stone surface at various angles, and the exposed height of the diamond will vary. As a result, the diamond is not evenly stressed, and diamonds with high exposure are prone to fracture. In order to improve this situation and make the diamond distribution more uniform, arrayed segments have emerged. Weld the arrayed segment on the blad...

-

Reasons for diamond wire saw broken

2020-12-29During diamond wire saw cutting process of the, it is under extreme conditions such as high temperature, high pressure, strong tension, and strong bending. The steel wire is fatigued and the diamond wire is broken. Then what are the specific reasons that can affect the broken the diamond wire saw?...

-

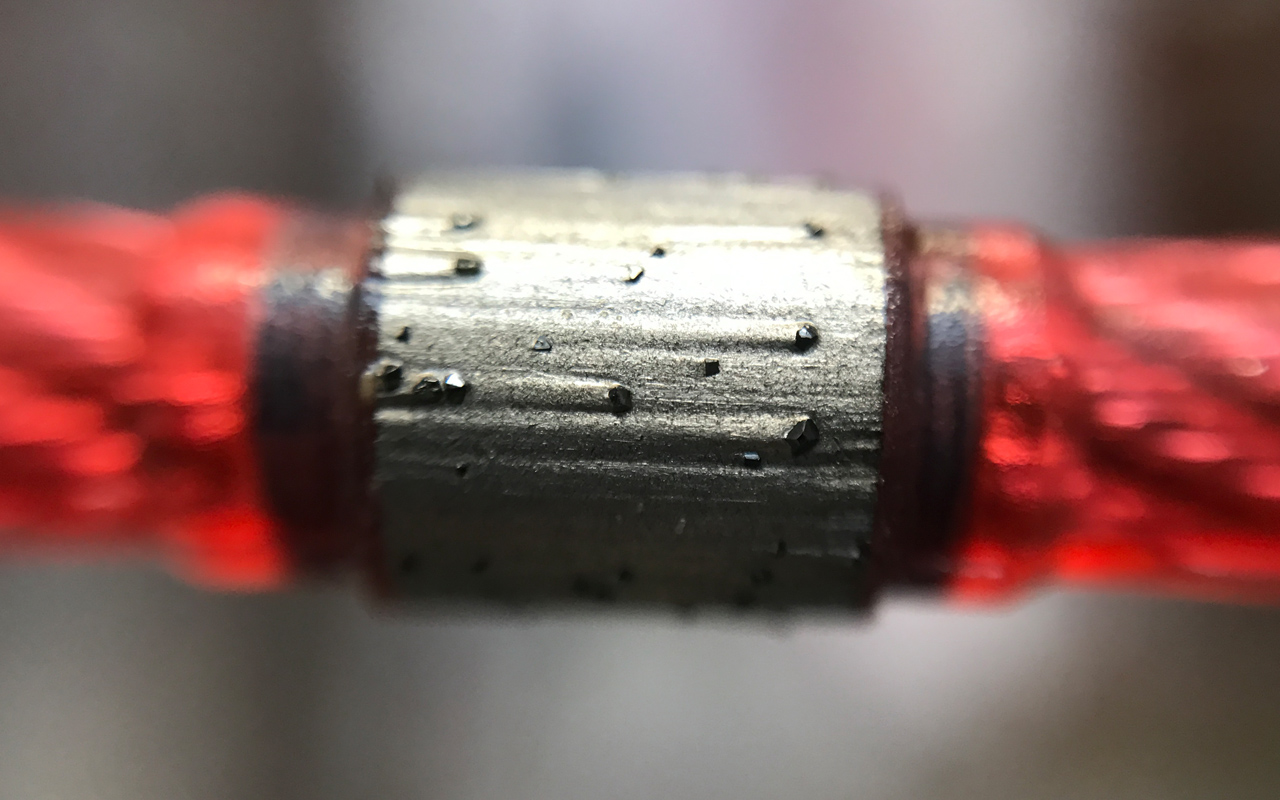

What should we do if the diamond wire saw is eccentrically worn?

2020-12-14The diamond wire saw is in the shape of a hollow cylinder. In normal use, the surface of the wire saw will continue to wear during cutting. Eventually, with the consumption of beads and rubber & plastic, it will eventually be scrapped. However, in practical applications, diamond wire saws often have various problems, such as eccentric wear problems often occur. This article introduces why the diamond wire saw eccentric wear occurs? How to solve the problem of eccentric wear? Let everyone better ...

-

The solution to bead rotation during diamond wire saw working

2020-12-14The diamond wire saw has some problems constantly during the cutting process. The loosening of the beads is very common. The specific performance is that the beads can be rotated at will. What is more verified is that the beads can even move forward and backward. The beads will not participate in cutting. In severe cases, the rubber around the beads will be worn away by the beads, and finally the beads will begin to grind the steel wire rope, which will eventually cause the wire rope to break. ...

-

What should I do if the diamond wire is cut?

2020-12-14Diamond wire saw is a diamond tool with steel wire rope as the core connection material. In the application, the wire rope is of poor quality, or melted by heat, or the cutting material is too hard, or the steel wire rope bending angle is too large, the joint is tightly pressed, etc. The situation that causes the diamond diamond wire to break occurs, but what should to doif the wire saw is broken? Many people don't know how to deal with it. This article will answer this question in detail....