-

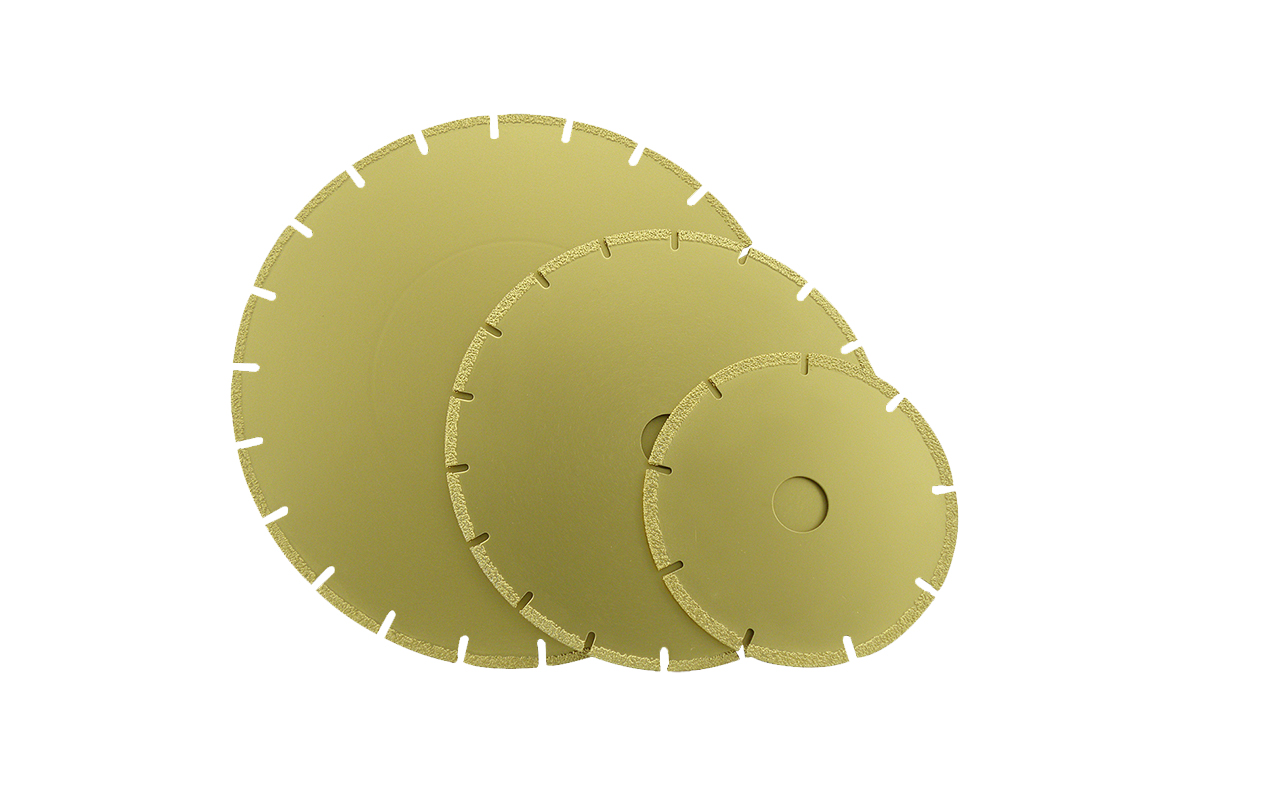

Vacuum brazed diamond tools

2020-09-09Vacuum Brazed diamond tools are one of modern diamond tools. Compared with traditional diamond tools, brazed diamond tools have the advantages of low diamond consumption, reduced tool costs, and high efficiency. Of course, the disadvantages are also obvious, cutting hard materials will make its low life, non-reusable, it increase the cost of sawing....

-

Commonly used bond for diamond segment

2020-09-09There are four commonly used bonds for diamond segment. These four bonds are matched with different diamond powders according to different materials to make diamond segments for different purposes. Each bond has its advantages and disadvantages. In the process of designing the diamond segment, we must take advantage and reinforce its shortcomings. This is the charm of diamond segment production and design....

-

Concept of diamond tools concentration

2020-09-02The volume ratio of diamond in the matrix is called the concentration, and the concentration can reach up to 400%, but this is an ideal situation. For most diamond tools, the concentration of 300% is already considered as the limit. At present, The concentration of brazing products is the highest....

-

Current status of diamond tools

2020-08-17Diamond tools are widely used in various fields such as geological prospecting, stone, machinery, automobiles and national defense industries. The manufacturing technology of abrasive tools, geological drill bits and stone sawing tools for mechanical processing has been greatly improved. ...

-

Advantages and disadvantages of diamond drill bits

2020-08-17Diamond drill bits have obvious advantages and disadvantages. The advantages are high hardness, high compressive strength and good wear resistance. But the shortcomings are also obvious, such as relatively brittle, easy to crack, and then low thermal stability, easy to become graphite with low hardness. This article helps us understand this part of knowledge....

-

Polishing technology and principle of natural stone

2020-08-17Natural stone needs to face the most basic technological processes such as cutting, grinding and polishing during the processing. Polishing is an important step in stone processing. We need to understand the polishing process and principles of stone processing, so as to facilitate us to master stone processing Basic knowledge also gives us a better understanding of the stone industry....

-

How to identify the sharpness of diamond circular saw blades

2020-08-17The most inescapable performance of diamond saw blades is its sharpness. A good saw blade has a very good sharpness, because it improves the cutting efficiency and saves time and cost in the stone processing, creates more Value. so, people are very concerned about the sharpness of saw blades. What kind of saw blade has good sharpness? This article will introduce in detail...

-

The composition and common specifications of diamond wire saws

2020-08-17Diamond wire saw is a new tool for modern stone processing. It is a cutting material that is most likely to replace saw blade products in the future. It is currently mainly used for concrete cutting and stone cutting. Under different cutting needs, diamond wire saws Products have become richer, with the most obvious changes in composition and specifications....

-

The structure and characteristics of diamond drill bits

2020-08-17Diamond bit is a very broad concept. It is a tool for drilling with diamond powder embedded in the bit body. Because diamond products are very rich, such as PCD, PDC, ordinary diamond powder, etc., it is formed a series of product lines of diamond drill bits. This article mainly introduces common diamond drill bits and their common structures and characteristics....

-

The control ratio of the metal content in the diamond segment bond

2020-08-17The diamond segment is composed of two parts of the bond and the diamond, and the bond is actually not just one component, it is made of paraffin, nickel, tin, zinc, copper, iron, silicon carbide, tungsten and other metal powders, and non-metallic powder, in which copper, iron, silicon carbide and tungsten are the main components, while nickel, tin, and zinc are the metal binders, which make the diamond and the bond more firmly....