YOU ARE HERE >

HOME >

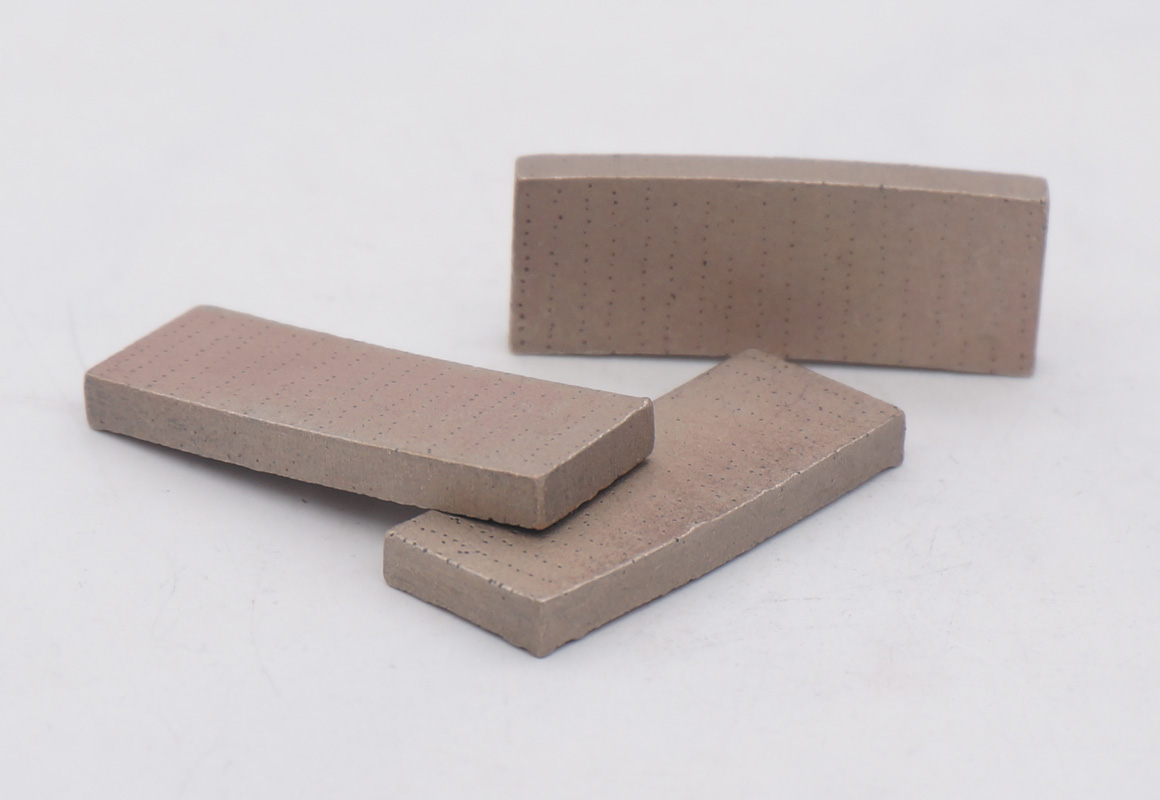

DIAMOND SEGMENT

Structure and characteristics of gangsaw segment

Publish Date:2021-02-03

Gangsaw segment is different from the circular saw blade segment. First, the gang saw segment is used on a gangsaw machine (also called a frame saw). This kind of saw blade uses a saw blade to cut soft stone, such as marble, soft granite, limestone and other blocks through reciprocating motion. Because of the different forces, the diamond distribution of the gangsaw segment is also different. Generally speaking, the diamond of the gang saw can be distributed on the front and rear cutting end. Due to the narrow cutting surface, in addition to high-strength diamonds, the requirements for matrix bond are also very high.

So what are the advantages of diamond gangsaws?

1: High output, cutting one cubic meter of marble blocks, especially for cutting large surfaces. Compared with the traditional large circular saw blade, the gangsaw blade can cut 7-13 square meters more slabs. For cutting expensive imported marble, this cutting method is undoubtedly the best way. At present, cutting luxury stones, most jade stones use this cutting method.

2: High efficiency, the cutting efficiency is 5-10 times higher than that of a large sand saw. Compared with a single circular saw blade, it is also 3-6 times more efficient. Compared with a single wire saw, it is 4-8 times higher processing efficiency, gang saw is the best cutting machine for marble cutting.

3: The processed slab has a high surface finish, and the subsequent surface processing can omit rough grinding, and only need fine grinding, polishing or direct polishing, which reduces the processing steps and increases the stone processing efficiency.

4: It can process larger stone blocks. Compared with ordinary circular saw blades, the diameter of the saw blade of 3000 meters is already very large, while the processed slab can only reach about 1300mm, but the gangsaw blade can processing large blocks with a height of 3 meters, the gang saw is a good choice in the process of cutting large slabs.

5: Save energy, greatly reduce energy consumption per unit output. Therefore, its comprehensive production cost is low, and it has gradually replaced sand saws. It is mainly reflected in the shortening of cutting time, saving of power and water consumption, as well as labor costs and corresponding reductions in management costs, which greatly reduces production costs.

6: The gangsaw segment has a longer life. The gangsaw segment uses a high-cobalt bond formula. Although its price is high, the cutting efficiency and life are greatly improved. In the process of cutting stone, the consumption is extremely low , So the gangsaw segment has a long cutting life.

Of course, gangsaw not good for cutting hard stone, such as for cutting granite. In addition, the price of the gangaw segment is expensive, and the welding cost of the segment also high. That’s why the gangsaw segment has not been widely promoted. But with the development of the times, people's demand for large slab is increasing, so in the future, gangsaw segment applications will be more and more, and the products will become more and more mature.

Tags:

The control ratio of the metal content in the diamond segment bond

2020-08-17

The diamond segment is composed of two parts of the bond and the diamond, and the bond is actually not just one component, it is made of paraffin, nickel, tin, zinc, copper, iron, silicon carbide, tungsten and other metal powders, and non-metallic powder, in which copper, iron, silicon carbide and tungsten are the main components, while nickel, tin, and zinc are the metal binders, which make the diamond and the bond more firmly....

Selection of diamond powder for diamond segment

2020-09-24

During the diamond segment working process, the role of diamond powder crystals is very important, especially in the cutting process, a good crystal can be very good in anti-breakage ability, reduce the power consumption of the equipment, and extend the life of the cutting....

Arrayed diamond segment and the saw blade

2020-12-29

In traditional diamond segment products, the diamond powder in the segment is arranged in disorder. During the cutting process, the exposed diamond will impact the stone surface at various angles, and the exposed height of the diamond will vary. As a result, the diamond is not evenly stressed, and diamonds with high exposure are prone to fracture. In order to improve this situation and make the diamond distribution more uniform, arrayed segments have emerged. Weld the arrayed segment on the blade steel body to be an arrayed saw blade....

Commonly used bond for diamond segment

2020-09-09

There are four commonly used bonds for diamond segment. These four bonds are matched with different diamond powders according to different materials to make diamond segments for different purposes. Each bond has its advantages and disadvantages. In the process of designing the diamond segment, we must take advantage and reinforce its shortcomings. This is the charm of diamond segment production and design....

Common problems and treatment methods of diamond segment

2020-08-17

Diamond segment is a non-standard industry in modern industry. The instability of product quality is the most common problem. The following are some of the most prone problems and related solutions in producing diamond segments. Through these instructions, Let everyone better understand the details of diamond segments production process....

Formula design of diamond segment

2020-10-16

Diamond segment is a very special segmented product. Through different formulas and different processes, products with different appearances, different cutting performances and different cutting life can be produced. The most attractive part of this product is that it is not Certainty, especially the new formula, needs to consider factors such as the object to be processed, the matrix metal bond, diamond grade and particle size, pressure and sintering temperature....

RETURN

RETURN