YOU ARE HERE >

HOME >

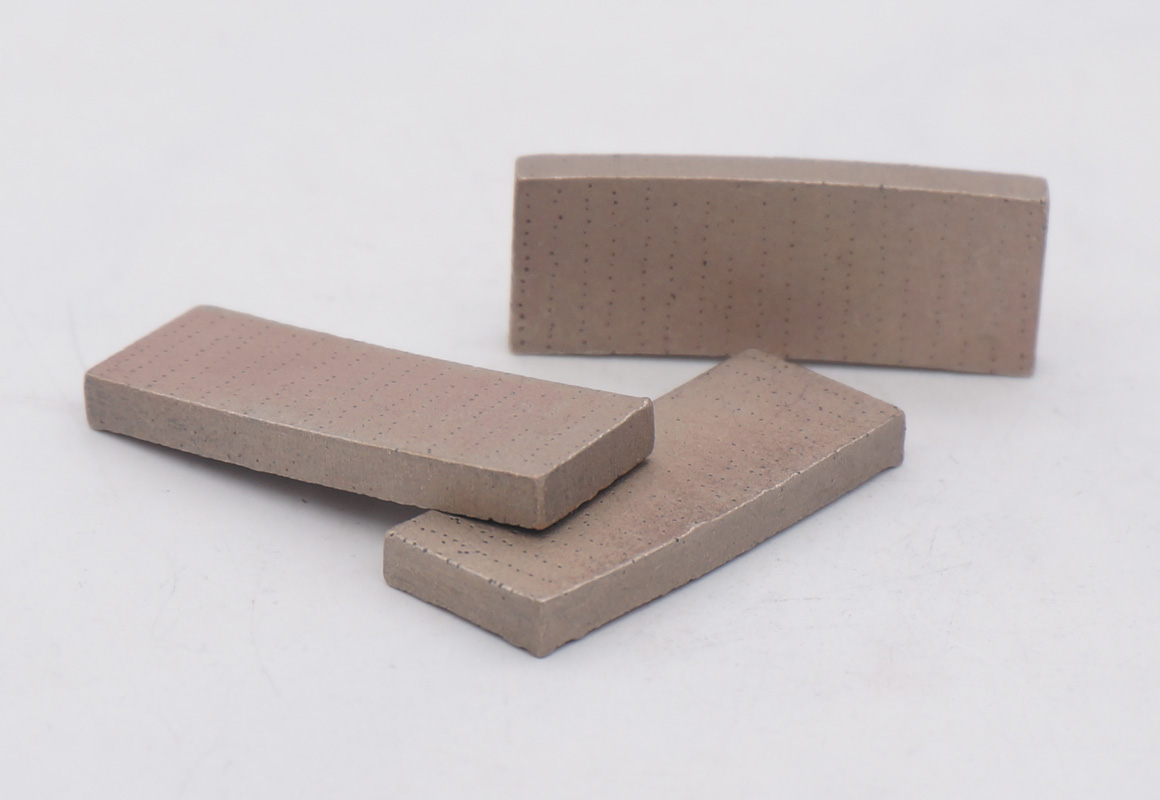

DIAMOND SEGMENT

The role of matrix binder in diamond segment

Publish Date:2021-02-03

Diamond segment is made of diamond and matrix bond through high temperature and high pressure sintering, so matrix bond is an extremely important part of diamond segment. Its composition is mainly metal powder, but also some non-metal powder. High temperature and high pressure form liquid metal. After cooling at room temperature, after the metal solidifies, a stronger sintered segment is formed, which plays a role in fixing the diamond. So does the matrix bond have any other functions besides fixing diamond? Let’s take a look:1. Dispersion and control of diamonds: Dispersion means that the diamonds can be distributed evenly. Many diamonds are together, in the process of cutting the stone, the impact and friction will cause the diamond to fall off very quickly. Therefore, in order to better increase the holding force, the best choice is to disperse the diamonds. Therefore, whether it is the preliminary work of the segment production process of stirring or in the later period sintering, it is intended to melt the metal so that the liquid metal can better disperse the diamond powder, and because the elements used in the matrix bond are mostly close for diamond, it also makes the diamond dispersion more uniform.

2. Make the diamond exposed to a certain extent and provide matching wear: After the sintering of the segment, it needs to be opened. After open, the diamond will be exposed, and the matrix bond is to expose the exposed diamond longer, so the cutting life will be improved, so the matrix bond is mostly matched with the selected diamond wear resistance.

3. Prevent the diamond from falling off prematurely. The diamond in the diamond segment cannot fall too early, so the matrix bond is required to hold it well, including physical and chemical holding power, and after the matrix is melted, it form a new chemical holding power, and at the same time, a harder sintered agglomerate is formed which improves the physical holding power. The two parts of the holding power are improved so that the diamond will not fall off prematurely. It also maximizes the use of diamond, saves material, and increases cutting life.

4. Acting as a heat sink to quickly transfer the heat generated during work: When the saw blade is cutting the stone, it generates a large amount of heat energy during continuous friction. This heat cannot be dissipated in a short time, so it needs to be cooled by cooling water , But if it is an insulator diamond, the heat dissipation is poor, the diamond will be excessively carbonized and the life will be shortened, and the metal matrix bond can help diamond segment to quickly transfer heat to the blade body, and it will be continuously sprayed by cooling water which greatly alleviate the large amount of heat generated during the cutting process.

5. When the diamond is impacted, the matrix bond bears and disperses the impact and load: the diamond segment in the cutting process, the strong impact force is given to the diamond, and the diamond alone cannot withstand it, so such impact will be pass to matrix bond to share the load.

Although diamond is a very important part of the diamond segment, the metal bond forming the united front with it also plays a very important role. Both are indispensable. The quality of which part is poor will cause the quality of the segment to deteriorate or unavailable.

Tags:

The control ratio of the metal content in the diamond segment bond

2020-08-17

The diamond segment is composed of two parts of the bond and the diamond, and the bond is actually not just one component, it is made of paraffin, nickel, tin, zinc, copper, iron, silicon carbide, tungsten and other metal powders, and non-metallic powder, in which copper, iron, silicon carbide and tungsten are the main components, while nickel, tin, and zinc are the metal binders, which make the diamond and the bond more firmly....

Selection of diamond powder for diamond segment

2020-09-24

During the diamond segment working process, the role of diamond powder crystals is very important, especially in the cutting process, a good crystal can be very good in anti-breakage ability, reduce the power consumption of the equipment, and extend the life of the cutting....

Arrayed diamond segment and the saw blade

2020-12-29

In traditional diamond segment products, the diamond powder in the segment is arranged in disorder. During the cutting process, the exposed diamond will impact the stone surface at various angles, and the exposed height of the diamond will vary. As a result, the diamond is not evenly stressed, and diamonds with high exposure are prone to fracture. In order to improve this situation and make the diamond distribution more uniform, arrayed segments have emerged. Weld the arrayed segment on the blade steel body to be an arrayed saw blade....

Commonly used bond for diamond segment

2020-09-09

There are four commonly used bonds for diamond segment. These four bonds are matched with different diamond powders according to different materials to make diamond segments for different purposes. Each bond has its advantages and disadvantages. In the process of designing the diamond segment, we must take advantage and reinforce its shortcomings. This is the charm of diamond segment production and design....

Common problems and treatment methods of diamond segment

2020-08-17

Diamond segment is a non-standard industry in modern industry. The instability of product quality is the most common problem. The following are some of the most prone problems and related solutions in producing diamond segments. Through these instructions, Let everyone better understand the details of diamond segments production process....

Formula design of diamond segment

2020-10-16

Diamond segment is a very special segmented product. Through different formulas and different processes, products with different appearances, different cutting performances and different cutting life can be produced. The most attractive part of this product is that it is not Certainty, especially the new formula, needs to consider factors such as the object to be processed, the matrix metal bond, diamond grade and particle size, pressure and sintering temperature....

RETURN

RETURN