YOU ARE HERE >

HOME >

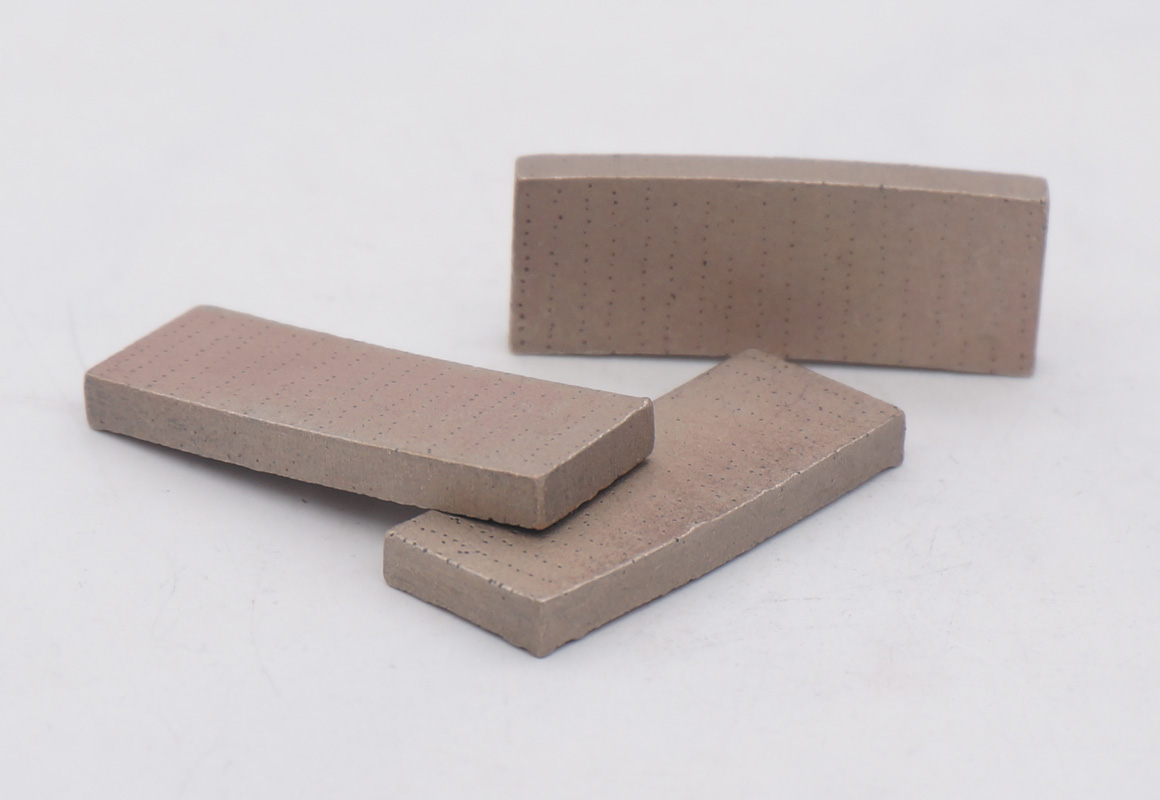

DIAMOND SEGMENT

How to improve the sharpness of diamond segment

Publish Date:2020-12-31

There are two important parameters for the quality of a diamond segment, one is the sharpness and the other is the service life. The higher the sharpness, the higher the grinding performance. The segment will become fast, stable, efficient and save in the process of cutting products. Time cost, labor cost, and energy consumption are reduced. Therefore, improving sharpness is a problem that diamond tool manufacturers must face. In terms of countermeasures, the following points can be improved:

The choice of diamond powder strength. Diamond saw blades rely on abrasives and cutting to process materials. Therefore, in the selection of diamond power with stable performance and not easily broken. Generally, diamonds with higher grades have better cutting results. Of course, all this depends on the object to be cut. If cut a softer stone use a higher grade and stronger hardness diamond powder, the segment will become blunt, resulting in a decrease in efficiency. Therefore, appropriately improving the diamond grade is one of the methods to effectively improve the cutting efficiency of the diamond blade.

Enhance the bonding level of diamond. A layer of strong carbon compound is plated on the diamond surface, which will form metal elements such as plating titanium, nickel, tungsten, etc., covering the surface of the diamond to improve the bonding of the diamond and increase the cohesion of the diamond. The diamond is not easy to fall off prematurely during the cutting process and keep the diamond sharp. This method is mainly to increase the holding force of the diamond through the matrix bond, thereby increasing the cutting performance of the segment. If the holding force is not enough, the diamond will fall off quickly, and the high-efficiency cutting requirements will naturally not be met.

Match the diamond particles correctly. Within a certain range, the sharpness of the saw blade changes with the concentration of diamond, the lower the concentration, the sharper the saw blade. Due to the high requirements of diamond hardness and elastic modulus, the segment needs to be sharp, and the diamond power grit requirements are different. After many manufacturing experiments, the best rate of the diamond grit coarse, medium and fine is 1:0.0227:0.071. Of course, these data are based on the current cutting performance, and there may be more configuration ratios, which require continuous research and development. In general, the diamond grit ratio will affect the cutting performance of the diamond segment.

The fine powder helps reduce the sintering temperature and strengthen the hardness of the matrix. The pre-alloyed powder shortens the contact time between the powder and the air, prevents the premature loss and segregation of low melting point metals, and enhances the holding diamond powder. Therefore, many manufacturers currently use pre-alloyed powder as the matrix binder, which also has a good effect. However, the price of this type of segment is higher. And for different processing objects, it is difficult to adjust the segment made of prefabricated alloy powder to the best.

Rare earth elements and the correct welding technology, rare earth elements can reduce the wear of the bonding agent, and the correct welding ensures that the diamond segment is not burned and does not drop.

In summary, the improvement of segment performance requires long-term continuous R&D and improvement to achieve breakthroughs. At present, there is still a long way to go if you want to break through the bottleneck in a short time and achieve revolutionary efficiency improvements.

Tags:

The control ratio of the metal content in the diamond segment bond

2020-08-17

The diamond segment is composed of two parts of the bond and the diamond, and the bond is actually not just one component, it is made of paraffin, nickel, tin, zinc, copper, iron, silicon carbide, tungsten and other metal powders, and non-metallic powder, in which copper, iron, silicon carbide and tungsten are the main components, while nickel, tin, and zinc are the metal binders, which make the diamond and the bond more firmly....

Selection of diamond powder for diamond segment

2020-09-24

During the diamond segment working process, the role of diamond powder crystals is very important, especially in the cutting process, a good crystal can be very good in anti-breakage ability, reduce the power consumption of the equipment, and extend the life of the cutting....

Arrayed diamond segment and the saw blade

2020-12-29

In traditional diamond segment products, the diamond powder in the segment is arranged in disorder. During the cutting process, the exposed diamond will impact the stone surface at various angles, and the exposed height of the diamond will vary. As a result, the diamond is not evenly stressed, and diamonds with high exposure are prone to fracture. In order to improve this situation and make the diamond distribution more uniform, arrayed segments have emerged. Weld the arrayed segment on the blade steel body to be an arrayed saw blade....

Commonly used bond for diamond segment

2020-09-09

There are four commonly used bonds for diamond segment. These four bonds are matched with different diamond powders according to different materials to make diamond segments for different purposes. Each bond has its advantages and disadvantages. In the process of designing the diamond segment, we must take advantage and reinforce its shortcomings. This is the charm of diamond segment production and design....

Common problems and treatment methods of diamond segment

2020-08-17

Diamond segment is a non-standard industry in modern industry. The instability of product quality is the most common problem. The following are some of the most prone problems and related solutions in producing diamond segments. Through these instructions, Let everyone better understand the details of diamond segments production process....

Formula design of diamond segment

2020-10-16

Diamond segment is a very special segmented product. Through different formulas and different processes, products with different appearances, different cutting performances and different cutting life can be produced. The most attractive part of this product is that it is not Certainty, especially the new formula, needs to consider factors such as the object to be processed, the matrix metal bond, diamond grade and particle size, pressure and sintering temperature....

RETURN

RETURN