Diamond tools are frequently used in the processing industry

Natural diamond has excellent characteristics such as high hardness, abrasion resistance, small friction coefficient, and good thermal conductivity. It is the ideal material for cutting non-ferrous metal and non-metallic materials. It uses natural monocrystalline apatite tools to cut fine ultra-fine parts. Began in the late 1950s. Later, it was required to process aspherical curved surface mirrors, and then to develop large mirrors. High shape accuracy and small appearance roughness were required. Now, the use of natural single crystal diamond tools is now Appropriately sophisticated, but because of its low output value, high price, and the appearance of artificial diamonds, the increase in the use of natural single crystal diamond tools in the field of fine processing has weakened.

Several types of artificial diamonds have excellent functional price ratios and Gradually sophisticated application skills have gradually occupied relatively fine processing malls with relatively low requirements. The excellent functions of diamond have determined its widespread use in machining. Non-ferrous metals such as copper, zinc, aluminum and other non-ferrous metals that are difficult to process are processed. In the case of alloys and alloys, these materials are attached to cutting tools and should not be processed. Diamond has a low coefficient of friction and has an affinity for non-ferrous metals. The diamond tool made can prevent the metal and the tool from sticking together. Because diamond has a large modulus of elasticity, the edge deformation is small during cutting, and the non-ferrous metal that is cut is kneaded and deformed, so that the cutting process is under small deformation. At the end, it can improve the quality of the cut surface. Processing non-metal materials that are difficult to process When processing non-metal materials that contain many high-hardness materials, such as glass fiber reinforced plastics, silicon-filled materials, and hard carbon fiber / epoxy composite materials, the hard points of the data make the tool wear severe, and it is difficult to process with carbide tools, while the diamond tools have high hardness and good wear resistance, so the machining efficiency is high. Ultra-fine machining follows the advent of modern integrated skills, and machining is becoming more advanced.

The development in the direction of accuracy puts forward high requirements for the function of the tool. Because diamond has a small friction coefficient, a low thermal expansion coefficient, and a high thermal conductivity, it can cut very thin chips, the chips simply flow out, and have a low affinity with other substances, making it difficult to produce Chips, small heat generation, high thermal conductivity, can avoid the influence of heat on the cutting edge and the workpiece, so the cutting edge is not easy to passivate, the cutting deformation is small, and high quality can be obtainedAppearance.

Use of brazing technology in diamond tool processing

Aspects of diamond tool performance improvement

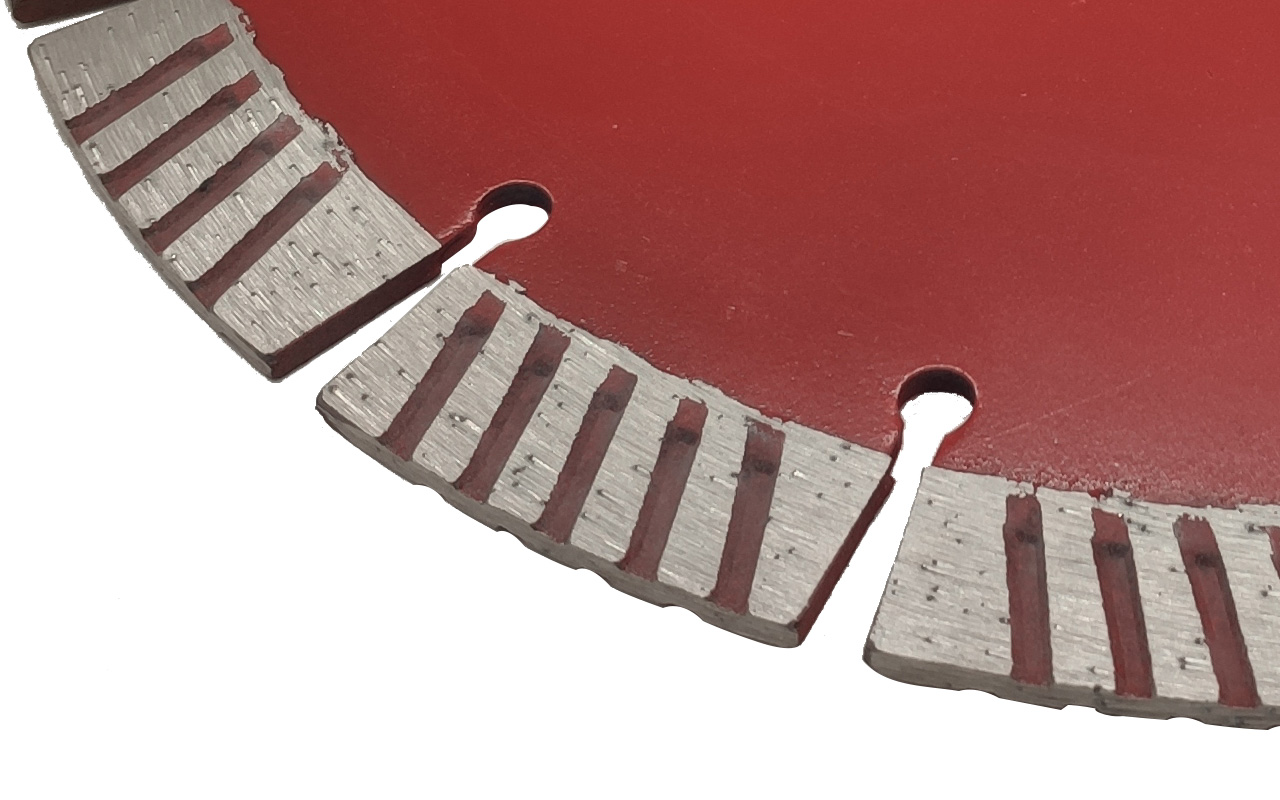

Summary of diamond tools for stone cutting

The development direction of diamond tools in the natural stone and civil engineering industries

Concept of diamond tools concentration

RETURN

RETURN