YOU ARE HERE >

HOME >

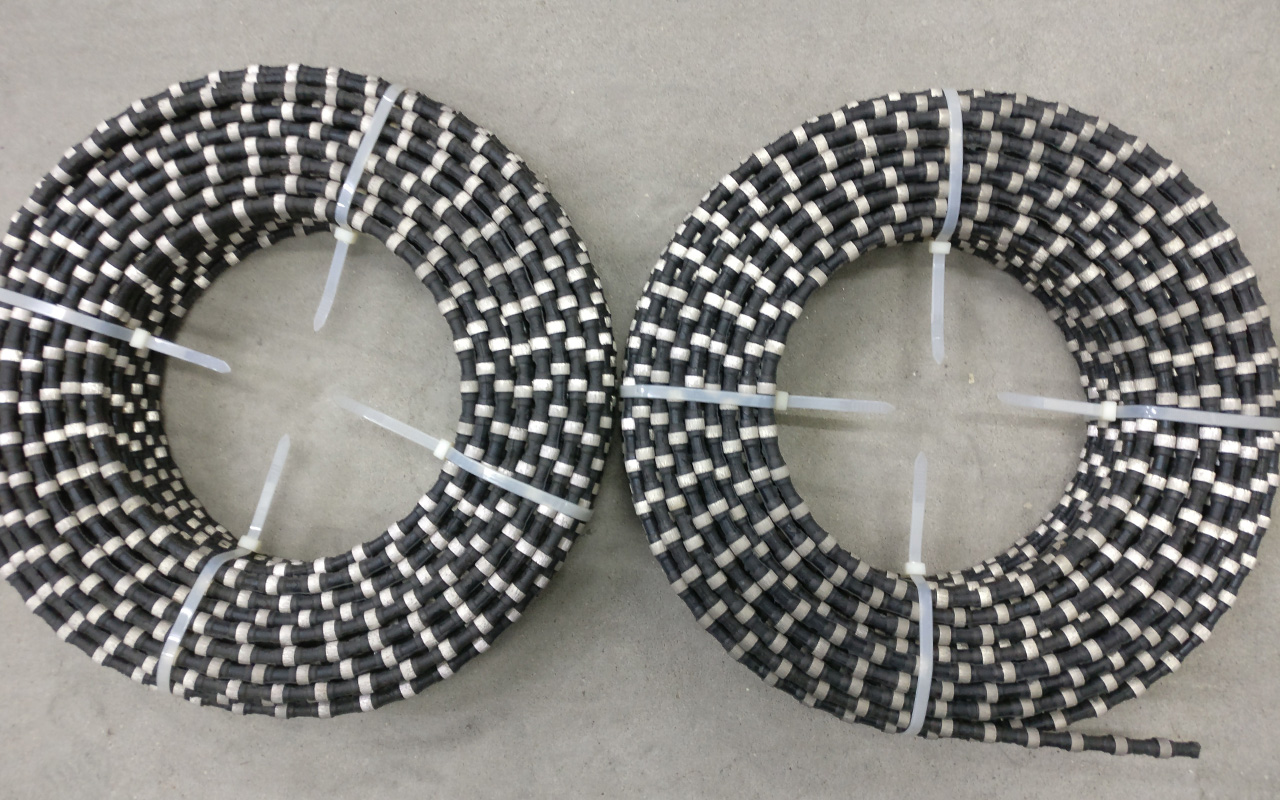

DIAMOND WIRE

How to use diamond wire saw for mining

Publish Date:2020-12-14

Quarry mining is a major project that requires a lot of manpower and material input. For example, roads must be built first. If there is no road near the mine, then even if the stone is extracted, there is no way to transport it out. It just needs water, electricity, no electricity, large machinery can not work, without water, the cutting process cannot be cooled, and the stone cannot be cut, and mining is impossible.

After the above basic conditions are met, there are prerequisites for mining. In general, diamond wire saw mining can be divided into four steps, namely, drilling, threading through holes, installing equipment cutting and adjusting. The following article gives a specific introduction to quarry mining:

The first is drilling. drilling is a key preparatory work. If the hole is not well drilled, it will directly affect the penetration of the diamond wire saw and affect the service life and cutting efficiency of the wire saw. Therefore, the process of punching is particularly important. for cutting a large block, it need to make three holes, one vertical hole and two horizontal holes.

Secondly, the diamond wire is threaded and perforated. At present, we mostly use the manual method of threading, fixing one end of the rope with a multi-strand loop cord, passing it in from one hole, and using iron wire to lead out from the other hole. In foreign countries, there is a method of animal threading, like mouse is tied to a wire and filled with water to allow the mouse to drill out of another hole.

Then install the wire saw machine. because the equipment is heavy, and after cutting a flat surface, the equipment needs to be re-adjusted, so it require a lifting equipment around it, which can be lifted at any time. After the equipment is installed, you can start cutting. Generally, the horizontal cutting is performed first, and then the vertical cutting is performed to prevent the wire saw from idling or jamming the beaded rope after the vertical cutting at the final stage of the horizontal cutting process. Must pay attention to the water supply during the cutting process, otherwise the large amount of heat generated by the cutting will cause the steel wire to deform, or the rubber will age, and the spring will melt and lose the role of fixing the beads, which will shorten the life of the wire saw.

Adjustment, In the process of mining, the bending angle of the wire saw is constantly shrinking. In the last part, the bending angle of the wire saw is very large, so at this time, we must pay attention to the running state of the wire saw. If there is sparks or the sound of the wire saw cutting is too large, it is best to find a good location and add a flywheel, so as to keep the wire saw from over-bending and causing deformation, thereby shortening the service life.

Tags:

Comparison of brazed diamond wire saw and electroplated wire saw

2020-10-16

The brazed diamond wire saw is to fix the diamond to the bead steel base by brazing. This is the third form of the wire saw since diamond wire saw birth in 1977. The earliest is the electroplated diamond wire saw, and the second is the sintered diamond wire saw. The brazed diamond wire saw is the third form. Compared with the earliest electroplated wire saw, this form has many improvements. This article mainly distinguishes the difference between the two through these obvious performance improvements....

Reasons for diamond wire saw broken

2020-12-29

During diamond wire saw cutting process of the, it is under extreme conditions such as high temperature, high pressure, strong tension, and strong bending. The steel wire is fatigued and the diamond wire is broken. Then what are the specific reasons that can affect the broken the diamond wire saw?...

Diamond wire saw classification

2020-12-14

Diamond wire saw is a kind of modern sawing tool. For cutting hard materials, it has the characteristics of small kerf and high efficiency, especially in cutting concrete and stone. Because the wire saw is a flexible cutting material, it is processing angle can be adjusted at any time and is currently widely used in the world. This article mainly introduces the classification of diamond wire saw products to let everyone better understand the wire saw products....

Advantages of diamond wire saw

2020-10-16

Compared with sawing tools, diamond wire saws have many advantages, such as higher cutting efficiency, more shapes of cut stones, and more thickness and randomness of cut stones. In addition, diamond wire saws can process all kinds of special-shaped stones, such as arc plates, which cannot be processed by saw blades. This article mainly combines the processing characteristics of diamond wire saws to let you know about diamond wire saws and their advantages....

Common problems of diamond wire saw

2020-10-16

Diamond wire saw is a new type of stone cutting tool. The wire saw has the characteristics of high efficiency, larger cutting surface, cutting angle adjustable and long service life. However, there are many problems in the cutting process. This article provides related solutions for the common problems of diamond wire saws....

How to use diamond wire saw correctly

2020-12-14

Diamond bead wire saw, also known as diamond wire saw, is a diamond tool based on high-quality steel wire rope, which is fixed with plastic, spring or rubber connecting pieces on the outside of the wire rope. It is mainly used for stone and concrete cutting. In the actual operation process, there are many safety precautions that need to be paid attention to in the diamond wire saw....

RETURN

RETURN